The advantages of eccentric reducer rubber expansion joint.

Nov-22-21

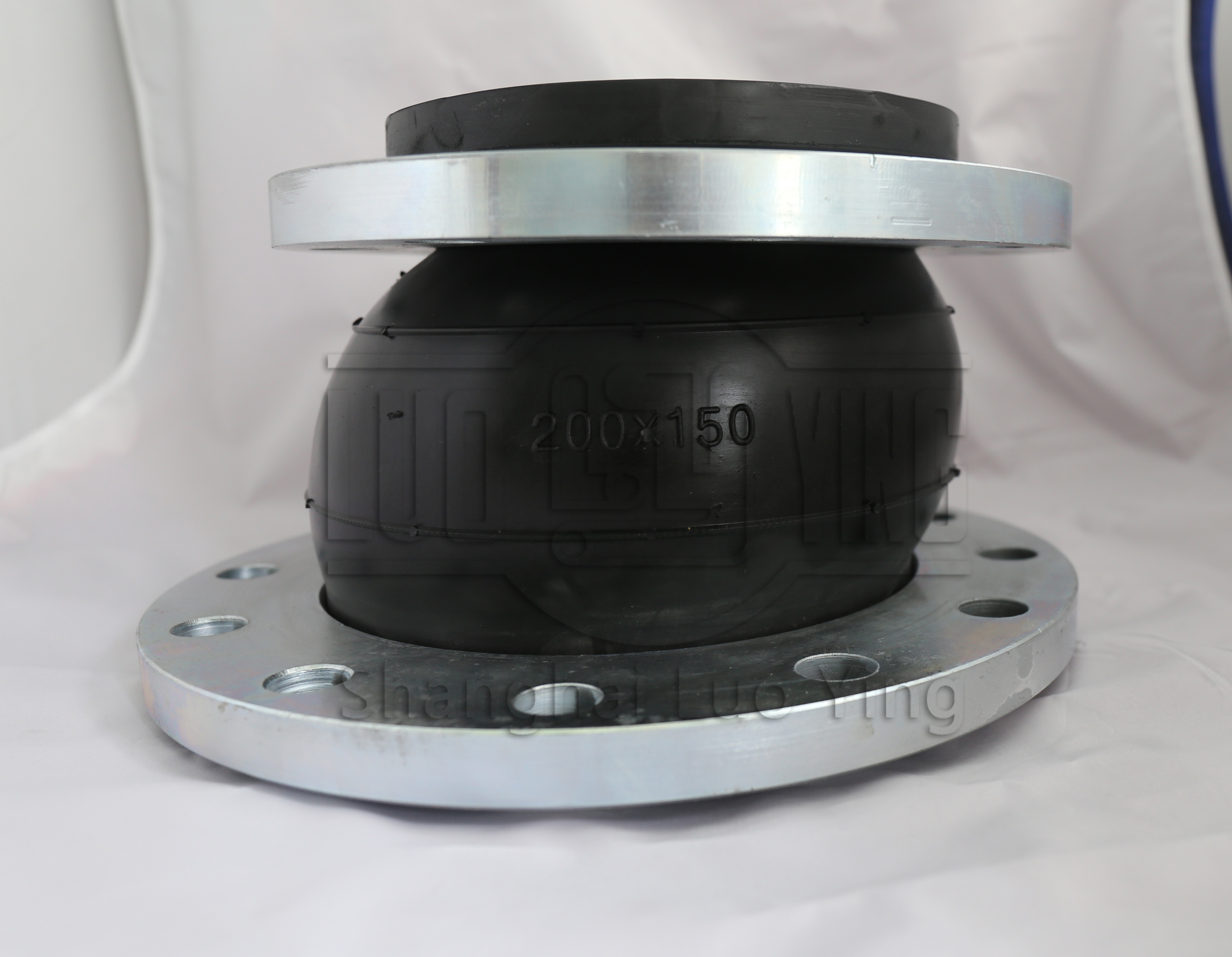

Bendable eccentric reducer rubber expansion joint is usually used natural synthetic rubber, production is made of inner and outer rubber and high strength, cold and heat stability of polyester cord fabric oblique intersection with the composite and steel wire ring composition of tubular rubber parts, after vulcanization molding and then with metal steel slotted flange is the combination of rubber expansion joint flange. With small volume, light weight, high pressure resistance, good ductility, large offset, balanced pipeline error, vibration absorption, noise reduction effect is very good, easy installation and other characteristics. It can deal with the problem of different specifications when connecting metal pipes, and at the same time has the effect of shock absorption and noise reduction, which is widely used in industry and can save pipeline construction parts and save costs.Special eccentric reducer rubber expansion joint is customized according to customer needs, which also has the above characteristics and can be widely used in water supply and drainage, circulating water, HVAC, fire fighting, paper making, pharmaceuticals, petrochemicals, ships, pumps, compressors, fans and other piping systems.

Pipeline installation eccentric size head: is used to prevent cavitation, and the size head of the pump inlet should generally be installed top flat, which is to prevent the accumulation of gas phase in the pipeline at the pump mouth, forming large bubbles into the pump cavity and damaging the pump. Only one case can be installed bottom flat.

Key features and efficacy of eccentric reducer rubber expansion joint: pipeline construction coaxial eccentric reducer: there is a difference between the pump inlet and outlet and external piping system software. Used to coaxial eccentric reducer pipe, can complete two different specifications pipeline parallel line coupling. Used to reduce the pipe of pipe warp.