Vibration Isolation

Vibration isolation can be achieved by using materials capable of providing a combination of highly elastic behavior in conjunction with damping properties. Pneumatic, hydraulic, elastic metal, and elastomeric designs are commonly used in commercial vibration isolation applications. Elastomeric materials are arguably most common and are extensively used in the industry with a very commonly used design consisting of elastomeric material bonded to metal plates or a metal core. Such isolators are typically called elastomeric mounts. Natural rubber, neoprene, and butyl rubber are some of the commonly used elastomers in commercial vibration isolators. Elastomers provide a designer with a range of stiffness and damping characteristics as well as an ability to withstand different environmental conditions. This ability to satisfy performance requirements over a wide range of rugged conditions along with the ease of manufacturing through a molding process make elastomers a common choice for isolators during the design process. Table 1.1 lists some of the commonly used elastomers for manufacturing passive vibration isolators with a listing of some of their characteristics that can be considered during design. In addition to the commonly used elastomers, manufacturers often develop proprietary elastomeric recipes to serve the needs of a specific design that may require a combination of properties from different materials. Properties of elastomeric materials can be changed significantly by changing their composition or by using different blends. A typical manufacturing process of the raw material involves vulcanization by adding sulfur and by the addition of accelerators, fillers, and plasticizers (Mark, Erman, & Roland, 2013). The raw material is then used in a molding process to produce a vibration isolator of the designed shape and size to deliver the necessary stiffness and damping properties. While there are many characteristics that are sought from the design of a vibration isolator, some of the common technical properties that a designer seeks to comprehend are damping, dynamic stiffness, environmental resistance, and some of the inherent nonlinearities.

-

Brand

BrandLUOYING

-

Classify

ClassifyPneumatic, hydraulic, elastic metal

-

Material

MaterialNatural rubber, neoprene, and butyl rubber

-

Common

CommonElastomeric materials

Product Range

-

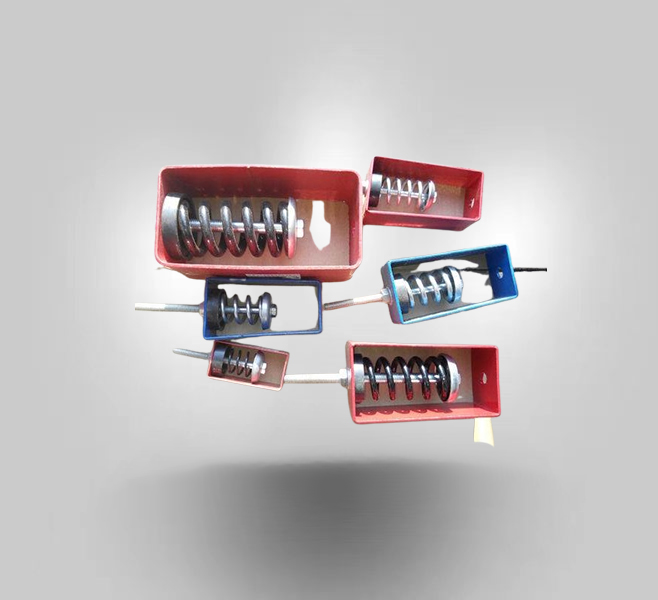

CR wire rope vibration isolator

1、The product has the comprehensive function and effect of vibration isolation and buffering, and the design structure is compact and simple.

2、The installation and use of a variety of setting methods can absorb the left and right. Up and down. Before anView More

-

GSG wire rope vibration isolator

GSG series stainless steel wire rope vibration isolator is a new vibration isolator redesigned and developed on the basis of GS series vibration isolator, its positive and lateral bearing capacity is basically close, the lateral is 70% of the positive bea

View More

-

ZTY type hanging spring vibration isolator

ZTY type spring vibration isolator is used in fan coil and other small equipment vibration damping, in the installation of central air conditioning, fan coil vibration isolation installation can improve the operation of the wind plate to extend the servic

View More

-

ZTA type damping spring vibration isolator

ZTA type damping spring vibration isolator main features and uses: ZTG type damping spring vibration isolator is composed of spring, upper rubber sleeve, lower rubber pad, upper and lower iron parts, etc. The vibration isolator has the advantages of simpl

View More

-

JS type combined spring vibration isolator

JS type combined spring vibration isolator uses multiple combined springs as the main body, the upper and lower configuration of steel plates and non-slip rubber pads, the product makes full use of the integrated steel spring low frequency and rubber vibr

View More

-

JD type damping spring vibration isolator

The difference between JD type spring vibration isolator and JC type is that the base area of the product has been doubled.

View More

-

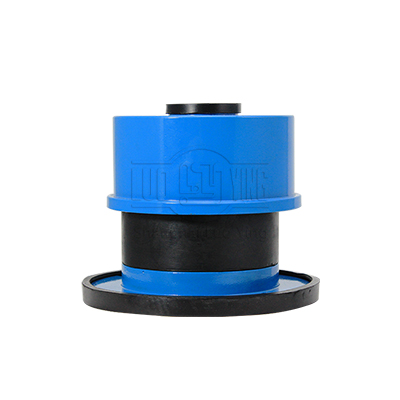

JNH Rubber vibration isolators

JNH mounts are fail safe marine engine mounts that have a higher profile, the high profile rubber section produces larger deflections and low natural frequencies. These marine engine mounts work the rubber in shear and compression. JNH mounts are designed

View More

-

HVG wire rope isolators

HVG wire rope isolators are special wire rope isolators that are small in size for applications in which space is limited. These wire rope isolators provide the same vibration and shock isolation capabilities as normal wire rope mounts just in a smaller s

View More

-

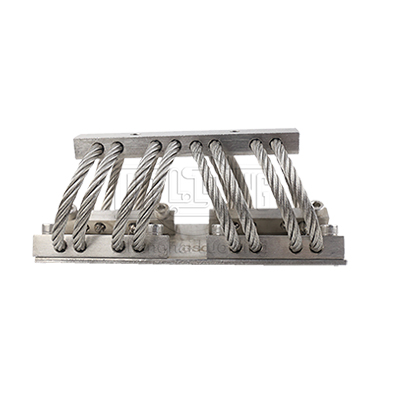

GS wire rope vibration isolator

wire rope isolators are large wire rope isolators that feature a large stainless steel braided cable for applications in which the most powerful vibration isolation is required. These wire rope isolators provide multi-dimensional vibration and shock isola

View More

-

JC type spring vibration isolator

The spring structure of JC type spring shock absorber is designed with low frequency value, strong pressure-bearing and small natural frequency, which has good anti-vibration effect for products and equipments. The spring base is made of nitrile rubber, a

View More

-

JB type damping spring vibration isolator

The upper and lower ends of the JB type spring shock absorber have screws and screw holes, and the upper end of the spring has a height adjustment nut, so the height can be adjusted freely according to the actual installation needs. The upper and lower en

View More

-

Type JA adjustable spring vibration isolator

Spring vibration isolators are mainly used in nuclear power plants, thermal power plants, chemical plants, steel plants and other pipelines and equipment anti-vibration. Commonly used to control the continuous fluid vibration excitation (such as fluid pul

View More

-

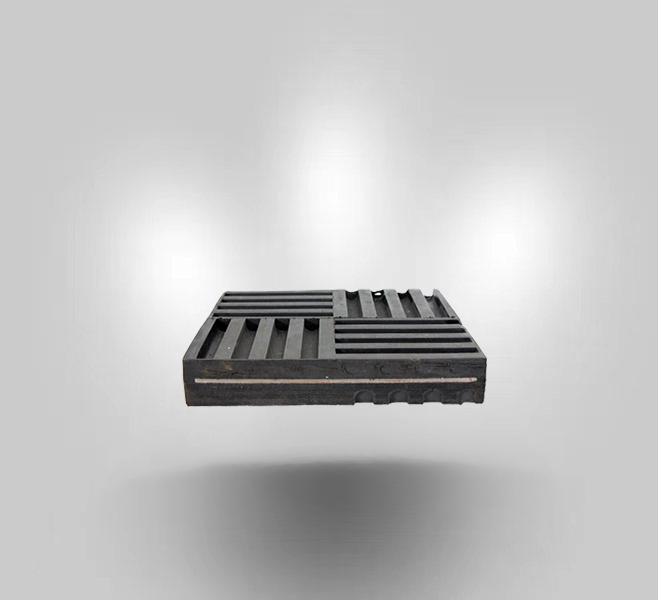

SD Rubber Damping Pad

View More

-

Rubber Cutting Vibration Isolator

Rubber Cutting Vibration Isolators are specifically designed to give high load capacity with relatively large static deflections and are compact in weight and easy to install. Normally, cone mountings are assembled with overload and rebound washers to con

View More

-

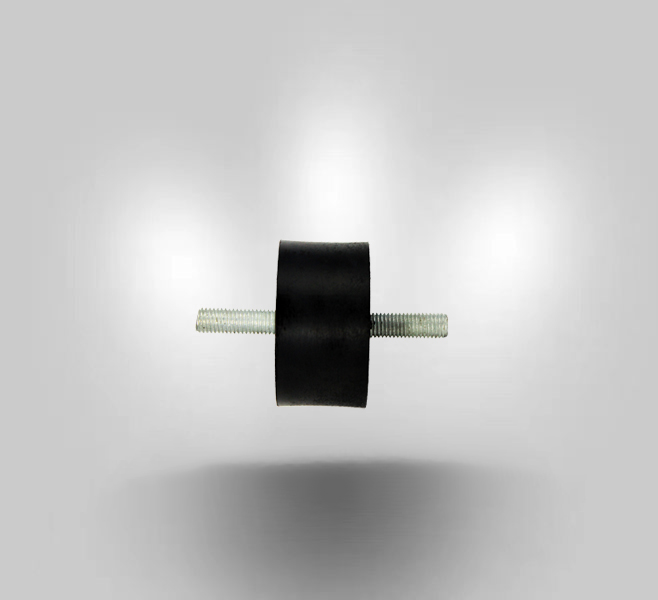

YZT Ruber shock absorber

YZT Rubber Shock Absorber can effectively bear all levels of load and deformation of wide range, especially suitable for the installation of electronic instruments.

View More

-

V hanger, suspension shock absorber

In suspension shock absorber simplest form, shock absorbers are hydraulic (oil) pump like devices that help to control the impact and rebound movement of vehicle's(or other equipment) springs and suspension. Along with smoothening out bumps and vibration

View More

-

JSD Rubber shock absorber

JSD Type rubber shock absorber is composed of metal and rubber composite material, the surface is covered with rubber, can prevent metal from corrosion.

View More

-

RM Rubber mount

View More

Customized Products

Technical Notes

Factors influencing the selection of passive vibration isolators

Shock Isolation

Shock can be described as a motion in which the velocity changes very suddenly causing a single or multiple impact into the ground or surrounding structure. Consequently, the theory of isolation outlined above is not applicable as the forcing (disturbing) frequency is usually low (less than 100 cpm). However, best results are obtained with isolators providing low natural frequencies. The design and selection of an isolation system for impact machines such as drop hammers and punch presses, must take into account that the energy of each blow is dissipated before the next impact occurs. when necessary, use of inertia mass and damping devices may be employed to attain desired stability.

Noise

An additional benefit of machinery isolation is the associated noise reduction. Introduction of a resilient medium between the equipment and the structure acts to break the path of structural borne noise. This results in noise reduction in areas outside the machinery room and to limited extent, in the area around the machine. This is achieved by reducing the sounding board effect normally associated with machinery mounted solidly to the structure. use of isolation does not reduce sir-borne noise if found to be above allowable levels. Air-borne noise must be treated acoustically with acoustic enclosures or other sound absorbing devices.

Location

In evaluating and selecting an effective isolation system, consideration must be given to identifying critical areas. In buildings where equipment is located directly over or adjacent to quiet areas, offices, libraries, studios, operating rooms, etc., a very critical condition exists, requiring extremely high isolation efficiency. Basement locations and areas with high ambient noise such as factories, warehouses, power plants, etc., are considered less critical and can tolerate larger transmitted forces. In addition, the geographic location of the building is also important. if located in a designated earthquake zone, the potential seismic forces produced will dictate the incorporation of restraints to protect the resilient isolated equipment.

Materials

After the desired static deflection has been established the isolating medium is selected. Steel springs and elastomers are generally accepted material that meet the requirements of resiliency for isolation.

Elastomers describes natural rubber and the various synthetic materials such as neoprene. It possesses inherent damping and sound deadening characteristics and can be molded into any shape or hardness and vulcanized to metal. The term rubber-in-shear is used to describe the deflection in shear rather than compression. Elastomers limit static deflection to a maximum of 1/2 inch and can be incorporated to provide damping in spring isolators.

Metal springs become preferable when the required static deflection exceeds 1/2 inch. they can be designed to provide large static deflection and depending on the application are available either free standing, housed or vertically restrained. Free standing springs are usually unrestrained devices which must be laterally stable meeting a minimum of 0.8 ration of spring diameter to compressed height. housed springs are used to counteract the effect of lateral forces, while vertically restrained springs are used for equipment whose weight varies with the addition or removal of large amounts of water and for rooftop equipment subject to wind loads. Since steel springs will transmit noise, introducing an elastomer pad to break the direct structural borne noise path is necessary.

Definitions

Frequency is defined as the number of complete cycles of oscillation that occur per unit of time.

Natural frequency is the number of complete cycles of oscillation a mass will vibrate in a given unit of time if a force displaces it from its equilibrium position and allows it to vibrate freely.

Disturbing frequency is the frequency of vibration produced by an unbalanced, rotating or reciprocating movement in mass.

Resonance is when the disturbing frequency equals the natural frequency of the isolation system resulting in an amplification of vibration producing an excessive violent movement. This is common as the system passes through resonance.

Static deflection is the distance an isolator will deflect under the static or dead weight of the equipment.

Spring rate is the weight required to induce a spring to deflect a given distance.

Damping is the ability of an isolation system to absorb and dissipate a significant amount of energy and convert it to heat. The importance of damping is to reduce the tendencies of the isolated equipment to "bounce." This occurs during acceleration or slowing of the equipment when the speed reaches resonance and the amplification of the unbalanced forces occurs. It will be noted, damping reduces the efficiency of the isolator. However, this reduction is so minor it can well be ignored or compensated, by a very small increase in the static deflection requirements for the isolation system.

Advantage

Nsure that the hose meets the published levels.-

environment

Resistant to high and low temperature, large temperature difference, high vacuum, strong radiation and corrosive environment. -

storage

High bearing capacity, fatigue resistance, no aging phenomenon, long service life and storage time. -

satisfy

It can meet the needs of damping, vibration damping, sealing, filtering, throttling and sound absorption and noise reduction, etc. It is the best substitute for ordinary rubber products and other porous material products under special industry and mining. -

performance

The performance index is designable, changing different process parameters and methods -

prepare

Can prepare metal rubber products with different structure size and performance characteristics. -

Applicable

Applicable to various fields such as aerospace, bullet ship and starship, national defense weaponry, petrochemical industry and automobile industry, etc., with distinctive characteristics of both military and civilian use.

Expansion joint accessories

Quality decides value-

Flange

Piping components can be bolted together between flanges. Flanges are used to connect pipes with each other, to valves, to fittings, and to specialty items such as strainers and pressure vessels. A cover plate can be connected to create a "blind flange" Flanges are joined by bolting, and sealing is often completed with the use of gaskets or other methods. Mechanical means to mitigate effects of leaks, like spray guards or specific spray flanges, may be included. Industries where flammable, volatile, toxic or corrosive substances are being processed have greater need of special protection at flanged connections. Flange guards can provide that added level of protection to ensure safety.

-

Covers

Fasteners are used for fastening and securing materials such as wood, metal, plastic, or concrete. They include nuts and bolts, threaded rods, structural bolts, machine screws, wedge anchors, washers, rivets, and more in a variety of types and sizes, including metric and inch.

-

Particulate barriers/purge connectors

In systems that have a media with significant particulate content (i.e. flash or catalyst), a barrier of ceramic fiber can be utilized to prevent corrosion and restricted bellows flexibility resulting from the accumulation of the particulate. Purge connectors may also be utilized to perform this same function. Internal liners must also be included in the design if the expansion joint includes purge connectors or particulate barriers.

-

Liners

A gasket is a mechanical seal which fills the space between two or more mating surfaces, generally to prevent leakage from or into the joined objects while under compression. It is a deformable material that is used to create a static seal and maintain that seal under various operating conditions in a mechanical assembly.