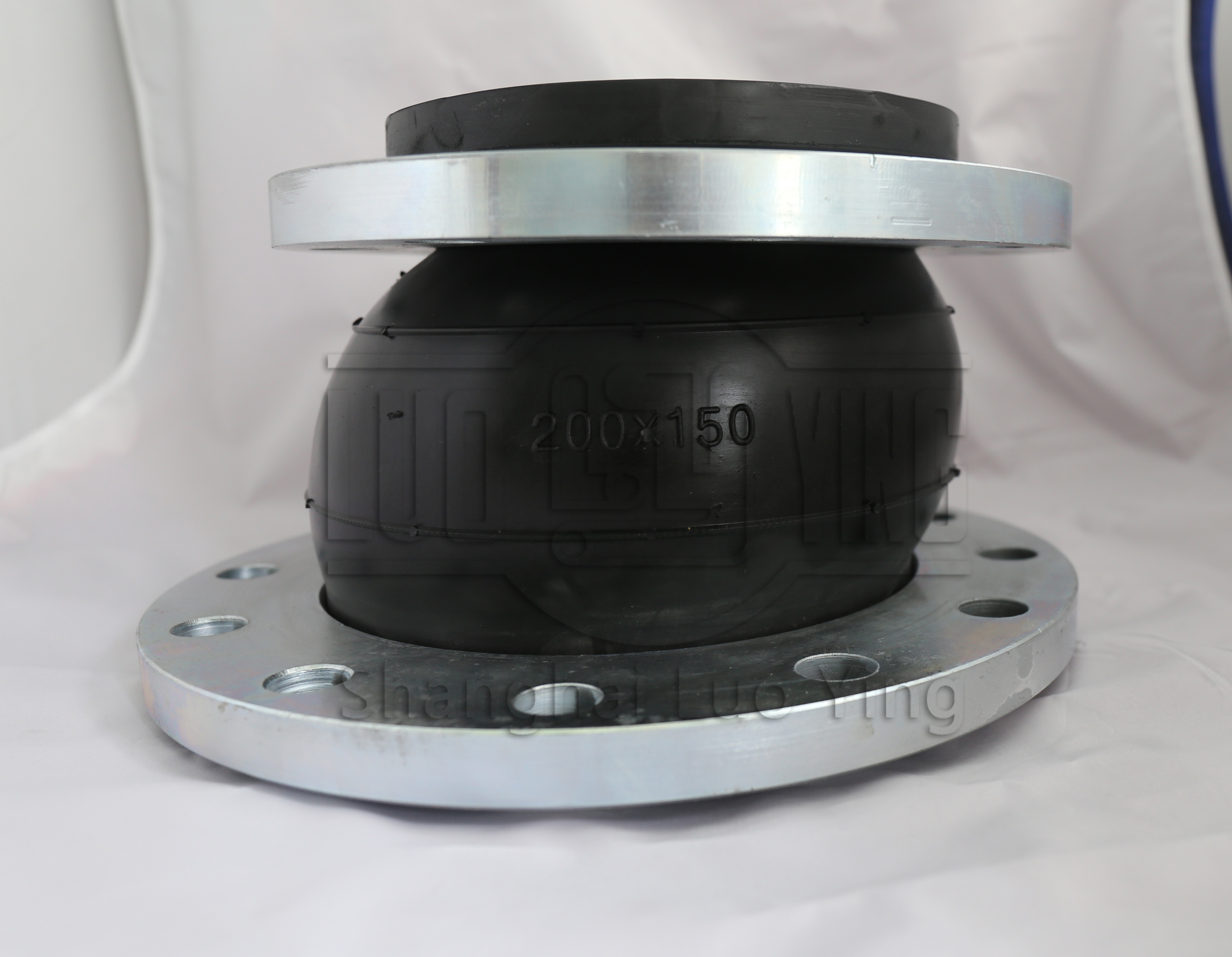

Installation of the reducer rubber expansion joint.

Nov-22-24

When installing the reducer rubber expansion joint, make it in a natural state and do not deform the product artificially during the installation process. This can avoid the early damage of the product and the weakening of the use effect, and the installation is strictly prohibited to exceed the displacement limit.If the installation is designed near the pump outlet or at the corner of the pipeline, when used in high-pressure, high-rise buildings, the pipeline has fixed brackets or fixed brackets, the fixed brackets and fixed brackets are subjected to forces greater than the axial force, otherwise, anti-drawing limit devices should be installed.

Reducing rubber expansion joint in the installation, shall make both ends of the sphere to enhance the ring (protruding part of the inner rigid wire rope) all stuck into the flange groove to prevent the pipeline pressure when the sphere and flange pull off. On the bolt, the first symmetrical bolts (six or four) tightened to ensure that the sphere in the flange of all in place.

When the reducer rubber expansion joint is used in close proximity to the water (oil) pump outlet or under frequent start-stop conditions, in order to reduce the length of the rubber expansion joint stretching and compressing too much to the pump and pipeline, the flange should be increased at both ends of the limit device.

When the rubber expansion joint is connected to the pipe flange, the bolt fillet should be extended to one end of the pipe flange to prevent the threads from being squeezed or stabbed when the arch of the rubber expansion joint is expanded under pressure, and the bolts at each end need to be tightened symmetrically under pressure so that all bolts are loosened and tightened in the same way.

Installation and use of large-diameter bendable rubber expansion joint, in order to facilitate the installation and reduce labor intensity, should be made in the flange end of a section of the appropriate length of short pipe, to be rubber joints and short pipe and the other end of the pipe is connected, and then the short pipe and the counterpart end of the long pipe welding.