The main role of rubber expansion joints in pipelines.

Nov-22-27

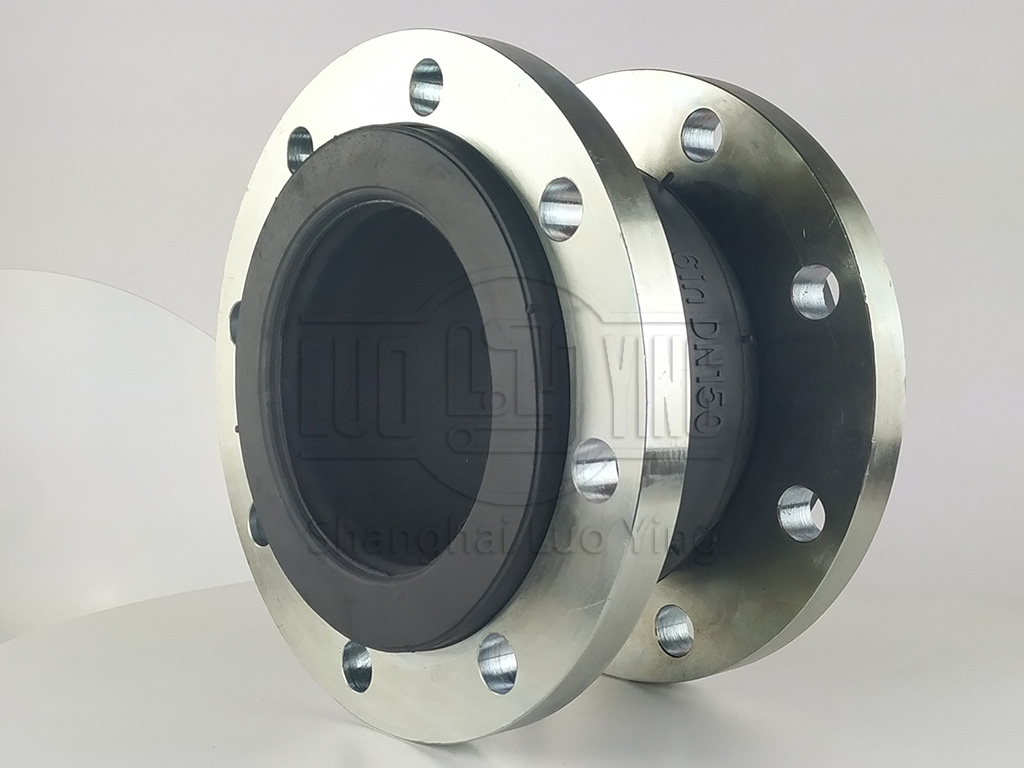

Rubber joints can also be called: bendable rubber joints, rubber flexible joints, soft joints, rubber expansion joints, shock absorbers, etc. It is a highly elastic, high airtight, media and weather resistant pipeline connection.According to the different materials, it can be made into acid-resistant, alkali-resistant, corrosion-resistant, oil-resistant, high-temperature-resistant, radiation-resistant, wear-resistant, aging-resistant and other varieties to adapt to a variety of media and environments. Widely used in chemical industry, construction, water supply, drainage, petroleum, light and heavy industry, refrigeration, sanitation, plumbing, fire-fighting, electric power and other basic projects.

It can reduce the noise generated by the vibration of pipeline pumps and so on, and has strong vibration absorption ability. As some pipelines work with strong vibration, it brings great threat to the service life of pipelines and causes great damage to the living environment. Because of the vibration conduction of flexible rubber joints, the pipeline is greatly protected and its service life is extended, which also brings improvement to people's living environment.

In the hot and cold changes of pipeline temperature, it plays the role of thermal expansion and contraction. Because of the elastic deformation effect of the rubber joint, it can be used in some pipelines with frequent hot and cold changes.

After installation, it can absorb lateral, axial and angular displacements produced by pipeline vibration; it is not restricted by the fact that the pipeline is not concentric and the flanges are not parallel.

Inside seamless high pressure rubber joints, in high temperature resistant, acid and alkali resistant, oil resistant pipelines more effectively prevent the erosion of corrosive media on the inner wall of rubber joints and improve the service life.