Performance and service life of damping dampers.

Nov-22-28

Damping damper performance and service life, to a large extent, depends on the choice of spring materials, so the total requirements for the manufacture of damping damper spring yellow is a high elasticity and fatigue strength, but also have sufficient toughness and plasticity, but because the spring is used in a wide range of different working conditions, so the spring material should also be selected according to its working environment and the requirements of the spring characteristics.

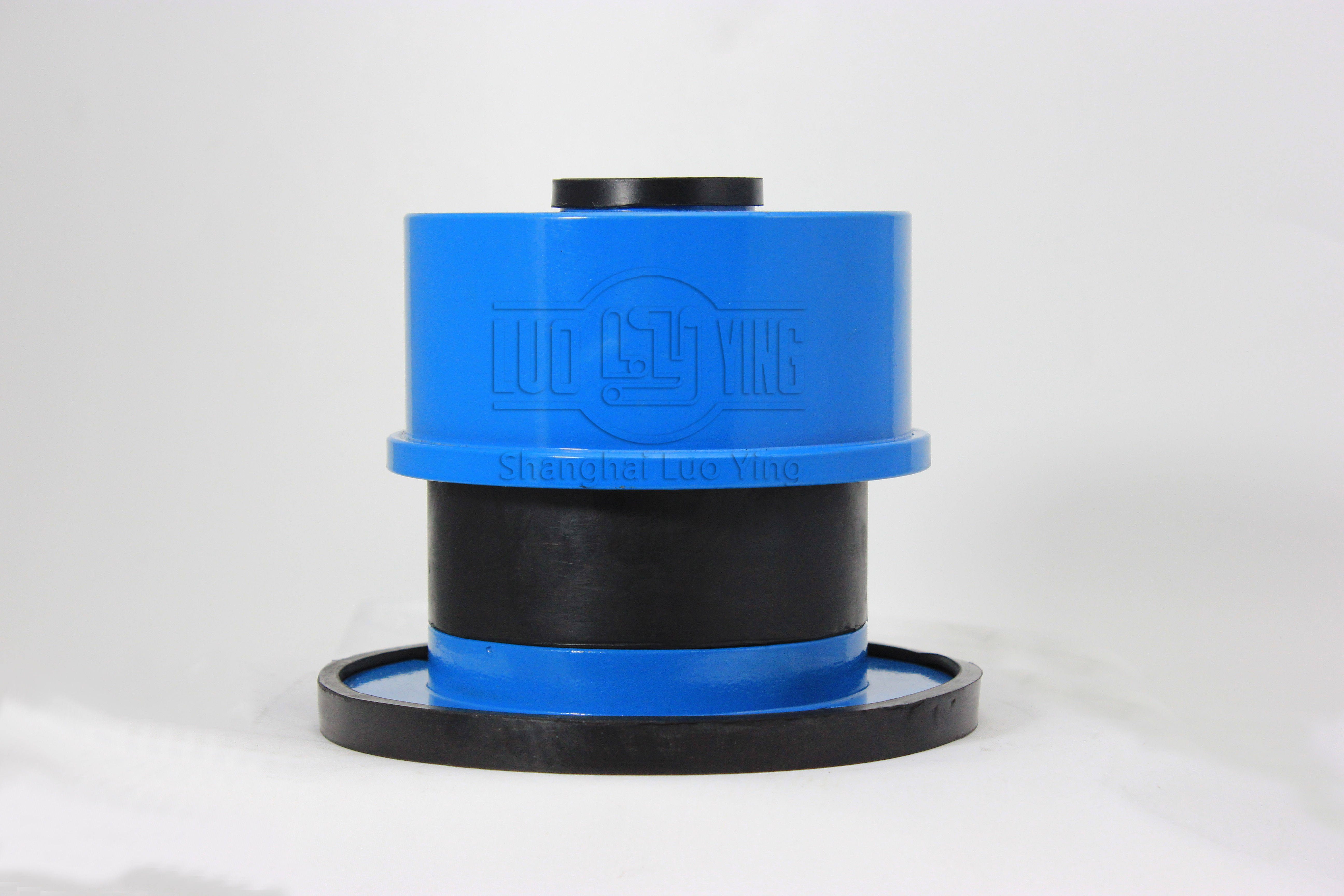

The structure of damping damper damping control system is developed and produced according to the external energy input can be divided into passive control, active control, semi-active control, intelligent control and hybrid control. Passive damping control of motors refers to the attachment of energy-consuming devices or sub-structure systems in certain parts of the structure low-frequency damping spring composite dampers, or the structure of the damping damper itself to make structural treatment of certain components, in order to change the dynamic characteristics of the structural system. Passive control does not require external energy input to provide control force, and the control process does not depend on structural response and external disturbance information. And because of its simple structure, low cost, easy maintenance and no external energy support and many other advantages shear dampers, so it has attracted wide attention of the engineering community, become the current application of the development of the hot spot, so many passive control technology is becoming increasingly mature, and in the motor damping damper installation projects are used. At present, the commonly used passive control systems are foundation vibration isolation, energy-consuming damping and vibration-absorbing damping.