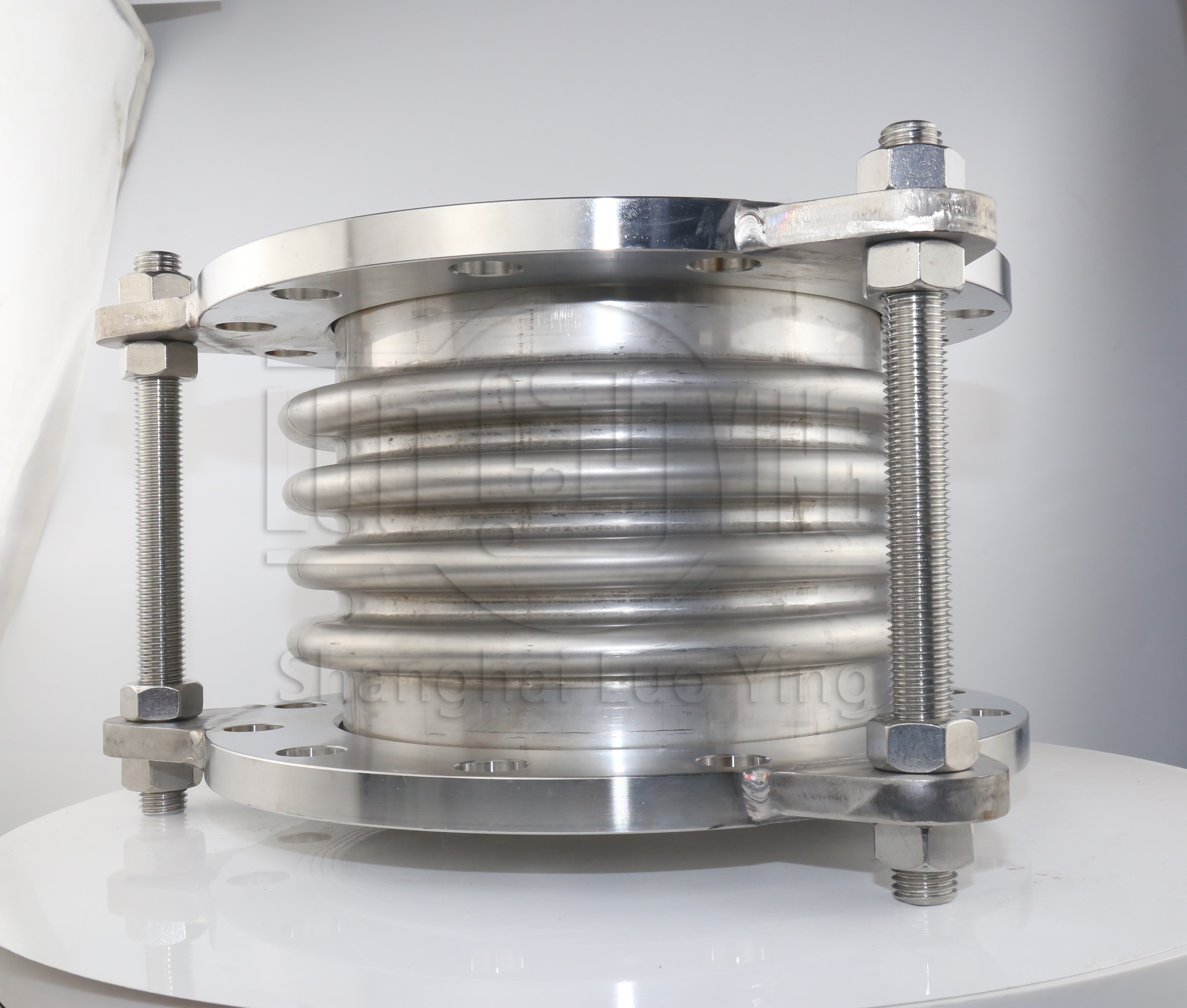

The main role of the flow guide tube in the expansion joint

Dec-22-02

When the medium passes through the bellows, the flowing medium can flow smoothly. As the bellows is bellows, it also reduces the vibration of the bellows caused by the flowing medium in the bellows, thus protecting the bellows in the case of special media, such as stones in the medium, gas, etc. The guide cylinder can play a wear-resistant, anti-corrosion role to prevent direct damage to the bellows by the medium after direct contact with the bellows, extending the service life of the bellows expansion joint.

2. Deflector role in the strong scouring force of the pipe expansion joint, can play a wear-resistant role, so that the bellows from media scouring, to extend the life of the role of the expansion joint.

3. In addition, the guiding role of the guide barrel can avoid the bellows instability caused by the expansion joint in absorbing the deformation of the pipe, so that the expansion joint to achieve its normal service life and role.

Generally speaking, the small diameter corrugated expansion joint with nominal diameter DN100 does not need to be lined with a guide barrel. On the one hand, it is easy to replace the small diameter corrugated expansion joint at a later stage. On the other hand, the size of the bellows is too small to weld the guide barrel in, so there is no need to increase the lining guide barrel. However, large diameter corrugated expansion joints above DN100 need to be lined with a guide barrel so as to really extend the service life of the pipe. Large-diameter corrugated expansion joints are inconvenient to replace and maintain later, and require additional lining guide barrels.

In general, the guide barrel will not be damaged in the early stage of use, but will not fracture in more than half a year of continuous use. It can be ruled out that under normal circumstances, since the guide barrel did not break at the beginning and then fracture occurred after six months of continuous use, so in general, it can be ruled out that resonance may occur due to the inherent vibration frequency of the guide barrel and the vibration frequency of the pipeline system under normal working conditions within ten days or ten days, the guide barrel will be damaged, and even the metal bellows will be damaged.