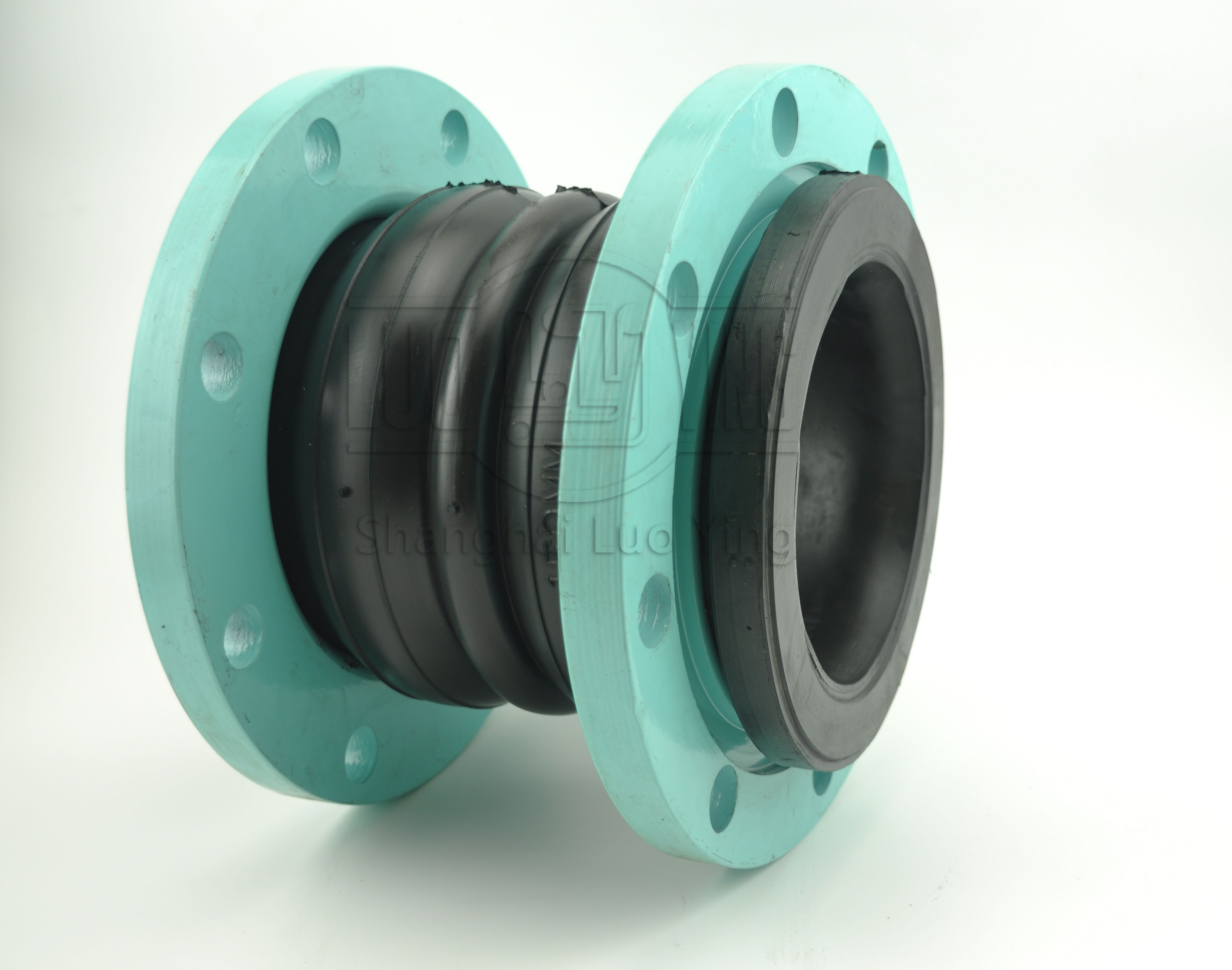

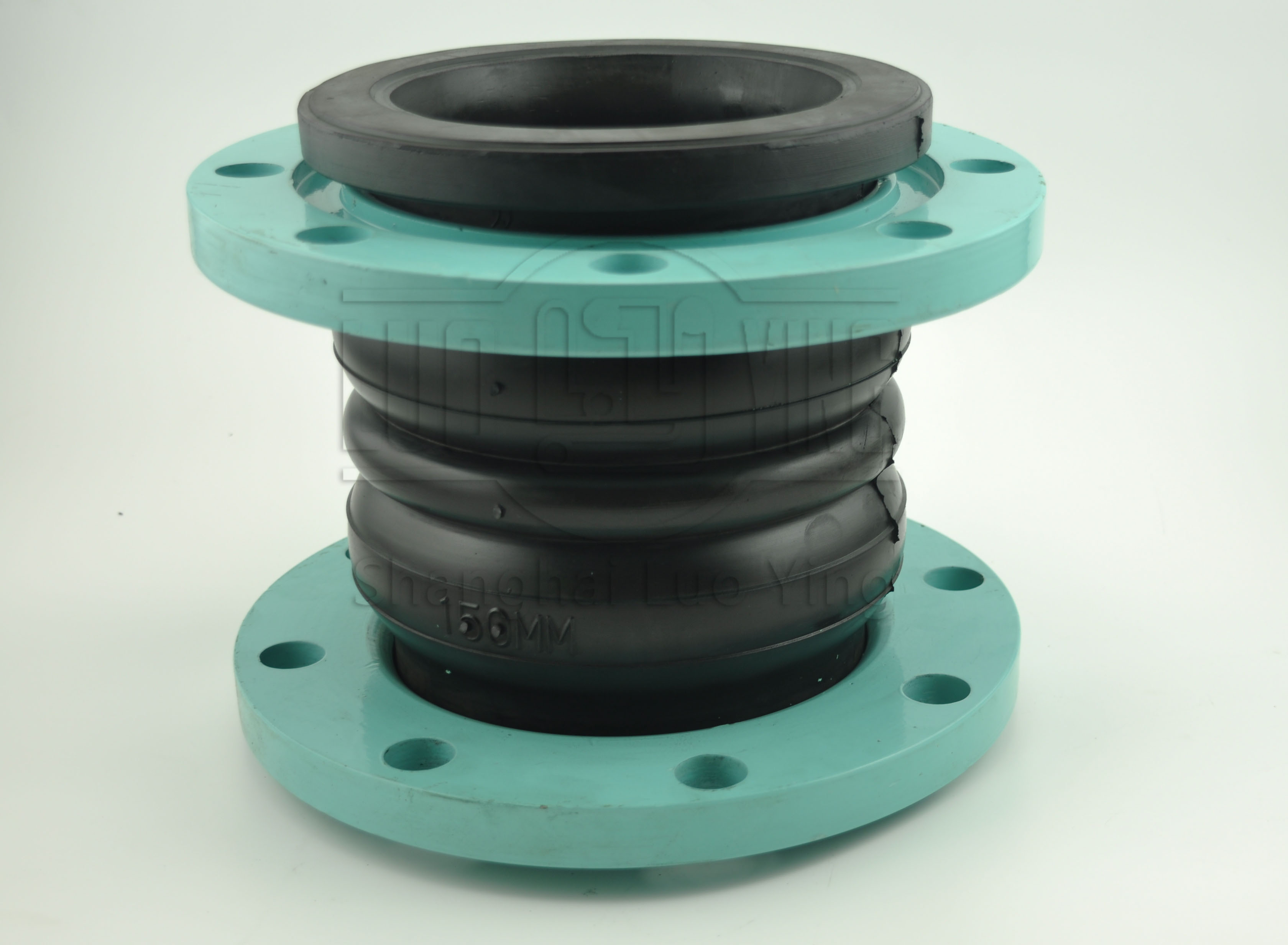

Double Dome Rubber Expansion Joint

Jan-23-24

Double sphere rubber expansion joints are flexible connectors made of natural rubber or synthetic elastomers, steel rings and fabric. When necessary, metal reinforcements relieve stresses in the piping system due to heat, mechanical vibration and/or movement. Rubber expansion joints relieve stresses caused by thermal expansion and cold contraction of the pipeline. Piping systems always move due to changes in ambient temperature, differences in the temperature and composition of the materials handled. Expansion joints absorb this movement, eliminating the risk of bending or opening, resulting in high replacement costs. Rubber expansion joints solve the expected vibration, noise, shock, corrosion, wear, stress and space problems. The piping system uses a double sphere design to absorb pipe movement, relieve stress, reduce system noise/vibration, compensate for misalignment/deflection and protect rotating mechanical equipment from start-up shock. Rubber expansion joints can be made of different rubber materials depending on the medium and application. They are designed to withstand axial, horizontal, angular and torsional movements and vibrations in pipelines. Some of the notable features and benefits of rubber expansion joints include superior noise and vibration control, easy installation of rotating metal flanges, availability of a wide range of flange materials, wide range of services, light weight, and the most economical flexible connectors.Multi-wave design increases the length of the rubber joint. Increased compensation. Special cold water . Hot water . Compressed air. Natural gas, etc. Unique design. Novel structure and good sealing performance solve the burst and damage of thermal expansion and cold contraction to the pipeline connection equipment, effectively improve the life cycle of the pipeline and the protection of the equipment. Double spheres have greater compensation than single spheres. Flexible double ball rubber joint. Double ball rubber flexible joint. Double sphere shock absorbing throat, joint specification: DN25-DN600, applicable range: acid. Alkali. Corrosion class. Oil. Hot water. Cold water. Compressed air. Compressed natural gas, etc. Joint material: environmentally friendly synthetic rubber, environmentally friendly green products, no lead and other toxic substances, vibration damping grade: A grade, excellent vibration damping, working temperature: -40 degrees to 80 degrees (high temperature resistant joints can also be processed).

Product advantages: Double ball rubber joints can reduce vibration. Reduce noise. Good expansion and contraction, easy to use. 1. Small size. Light weight. Good elasticity. Easy to install and maintain. 2. Axial. Angular displacement, not limited by the pipeline is not central, the flange is not parallel. 3. Due to the good comprehensive performance of double sphere rubber joint, it is widely used in chemical industry. Construction. Water supply. Drainage. Petroleum. Light and heavy industry. Refrigeration. Sanitation. Plumbing. Fire fighting. Electric power and other basic engineering is especially suitable for vibration. The pipeline with frequent changes of heat and cold. Product features: double sphere rubber joint has high elasticity. High air tightness. Media and weather resistant pipe joints. High internal density. Can withstand high pressure. Good elastic deformation effect. Compared with single sphere, double sphere has greater compensation capacity. This product is manufactured by huanzhong/luoying water supply using the new process of air-blown mold, which is the inner rubber layer. Reinforced layer. Middle rubber layer. The outer rubber layer composite product composed of spheres and loose-set forged low carbon steel flanges has high pressure resistance. Good elasticity. Large displacement. Good vibration absorption and noise reduction effect, easy to install. Can be widely used in water supply and drainage. HVAC. Fire fighting. Compressor. Paper making. Pharmaceutical. Ship. Water pumps. Fans and other piping systems. Rubber joints are composed of rubber parts and loose metal flanges, used for pipeline vibration and noise reduction. Compensation displacement joints. huanzhong/luoying water supply strictly in accordance with international standards and raw material quality requirements, to eliminate the phenomenon of cutting corners. Environmental protection standard is the product raw materials not only need new materials, but also need new materials of environmental protection grade.