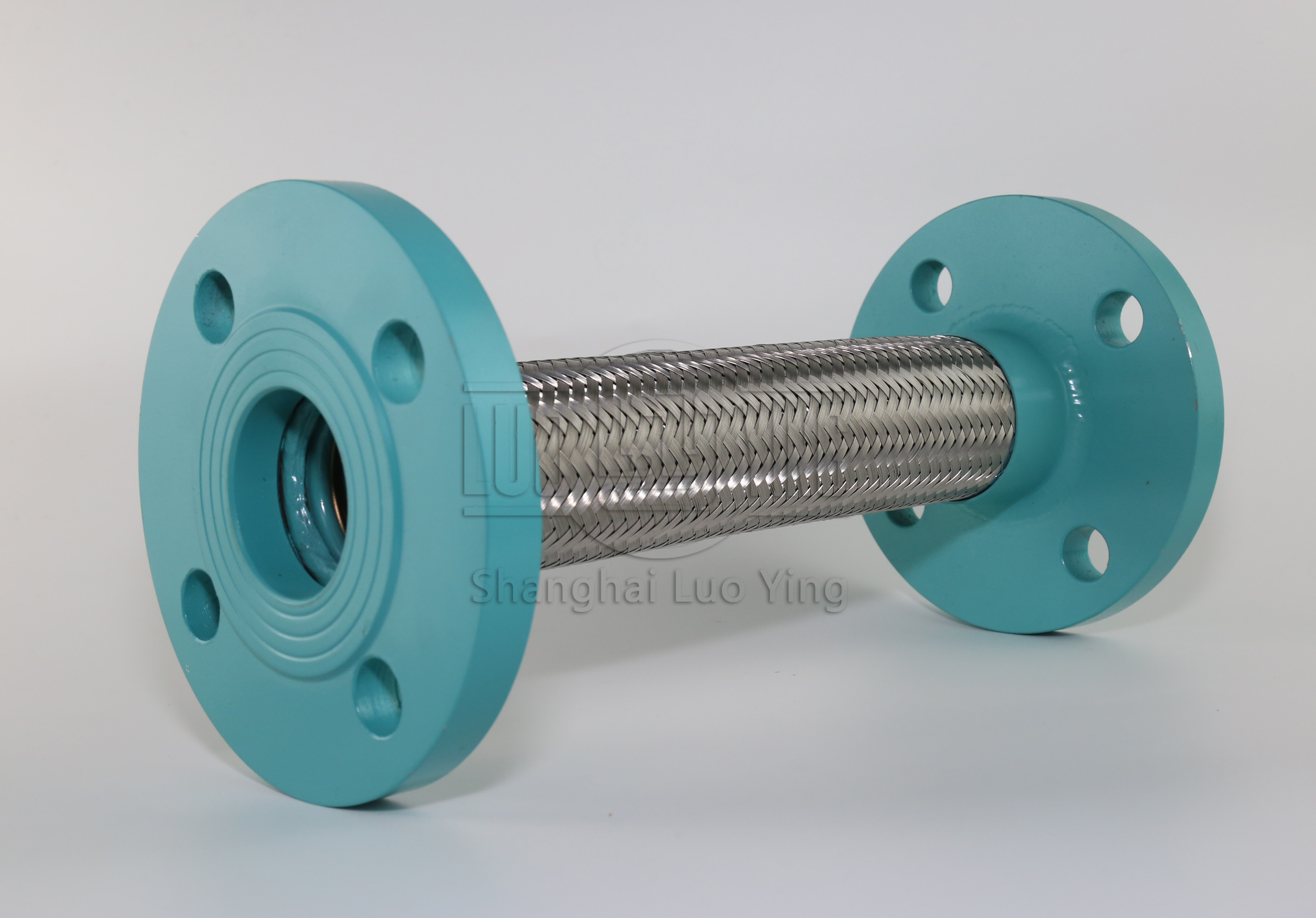

Stainless steel metal hose material and standards

Jan-23-24

We must choose the right shape of stainless steel metal hose when we use it, otherwise if the forced bending of the hose, may cause damage such as breakage of the wall of the stainless steel metal hose, and the pressure at various places in the tube will also change, which may be beyond the range of the working pressure of the stainless steel metal hose designed for the earrings. Length. As for the length of the stainless steel metal hose, we all know that the length decisively can not be used, but for too long stainless steel metal hose some feel that it does not matter. But in fact this is a wrong idea.Stainless steel metal hose in the use of the inevitable bending, even if the degree of bending stainless steel metal hose can withstand, but in the transport of materials at the bend of the tube body to withstand the pressure will also have a certain degree of increase, so in the normal form of stainless steel metal hose can withstand the working pressure, in the bend is likely to withstand. Stainless steel metal hose outer rubber layer sometimes very serious deterioration phenomenon, this phenomenon is usually caused by the aging of stainless steel metal hose, belongs to the natural aging deterioration, which is due to the outer rubber layer long-term exposure to oxygen, with the deepening of time, the oxidation of its surface covered with a layer of ozone.

Stainless steel metal hose installation to try to avoid heat sources, away from the performance of the engine exhaust pipe. If necessary, a casing or protection screen and other devices can be used to avoid heat deterioration of the hose. Stainless steel metal hose cross or work may be friction with mechanical surfaces, the application of hose clamps or springs and other protective devices to avoid damage to the outer layer of stainless steel metal hose. Stainless steel metal hose bending, bending radius should not be too small, should be greater than 9 times the outside diameter. Stainless steel metal hose and the joint connection should be a straight section greater than 2 times the outer diameter of the tube.

Stainless steel metal hose should be installed to avoid being in a tensioned state, even if the ends of the hose have no relative movement, but also to keep the hose, tensioned hose under pressure will expand, the strength is reduced. Do not twist the stainless steel metal hose during installation. Stainless steel metal hose by a slight twist is likely to reduce its strength and loosen the joint, assembly should be tightened on the joint in the hose, rather than the hose tightened on.