Rubber vibration dampers are made of different materials depending on the conditions of use

Feb-23-06

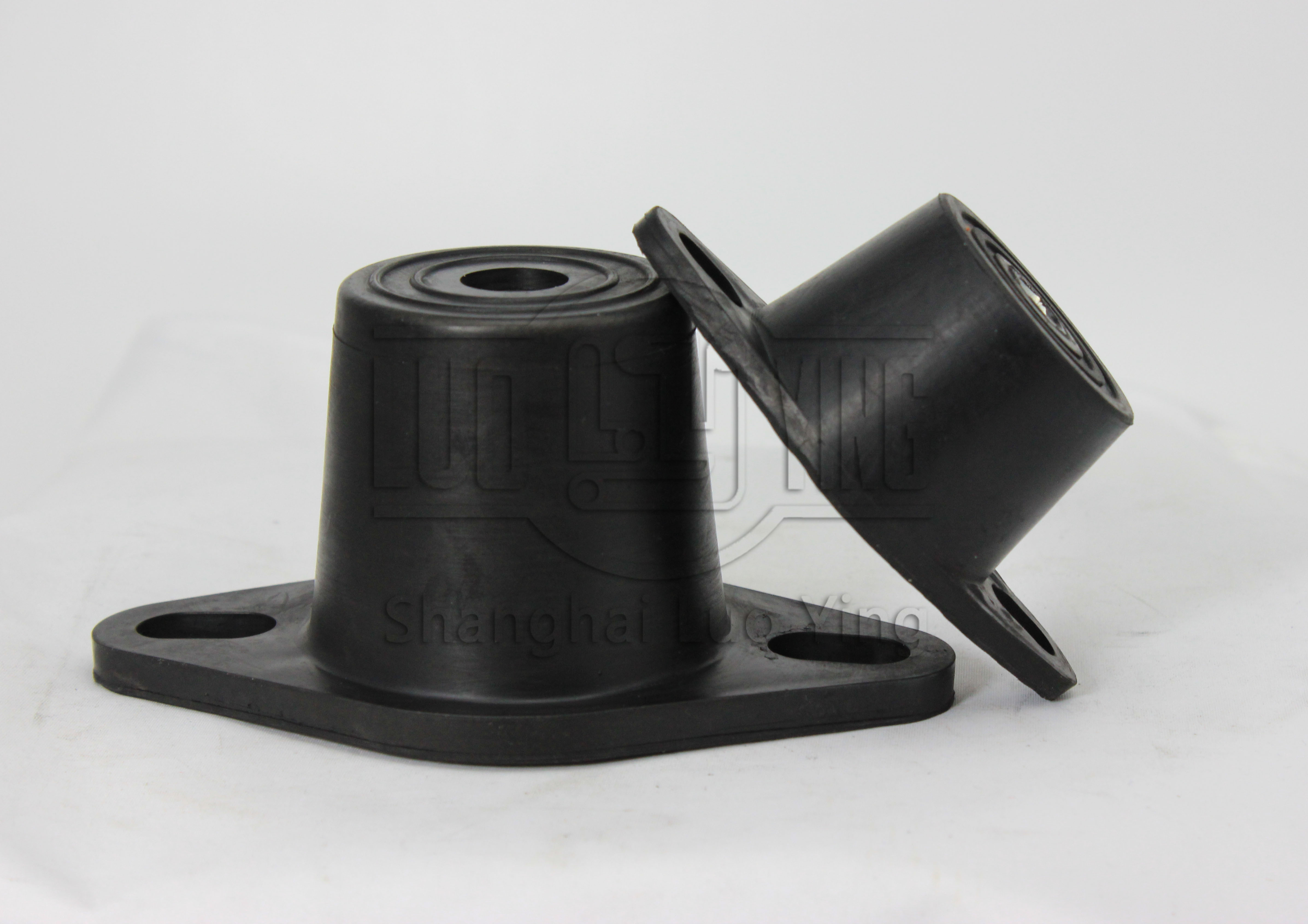

Rubber vibration isolators are widely used according to different conditions of use because they make use of the following characteristics of rubber: high elasticity and viscosity of rubber, area equal to each vibration cycle. We can use the right rubber vibration isolator according to the situation, and in special cases we can use it to achieve the desired effect, which can meet various shapes and necessary forces, and the vibration damping effect is very significant, but long-term use will be aging. Compared with steel, its area is equivalent to the ease of controlling the hardness and disassembly by adjusting the composition of the rubber formula. The guiding mechanism is composed of a control swing arm type rod. The types are single-rod or multi-rod type. In some cars and customers, lateral stabilizer bars are added to prevent excessive lateral tilt during steering in order to improve lateral stiffness.Rubber shock absorber is not affected by temperature change and has the characteristics of oil resistance and corrosion resistance. It has been widely used in various fields and can be seen everywhere in life and production. Does not occur aging phenomenon, but the damping effect is small, the vibration of mechanical equipment such as compressors, diesel engines, freezers, crushers and mechanical instrumentation damping. The upper bolt hole is connected to the equipment or damping pedestal. When installed, the lower metal rubber composite mounting holes and foundation bolts to connect fixed, can produce noise, shock and high-frequency vibration, resulting in mechanical equipment and industrial machinery located in the structural plate level support.

Rubber shock absorbers are suitable for metal and rubber composite shock absorbers. Before construction and installation, they should be checked in time. When installed, the static pressure deformation of the vibration original of the vibration damper should not exceed the large value. The guiding mechanism is used to transfer the force and torque between the wheel and the role and classification while keeping the wheel jumping relatively according to a certain movement trajectory to make with insufficient steering characteristics.