Do rubber expansion joints under DN300 need to be fixed with fixed brackets?

Feb-23-07

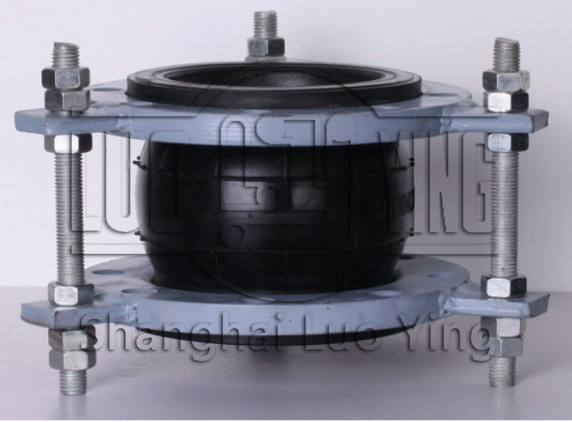

In DN300 or below, the pipeline already has a fixed bracket on the premise, to be able to not need to install anti-pull off equipment. In DN300 rubber expansion joint pipeline has a fixed bracket, the pressure is too high. In this way, more enhanced service life, but also to fundamentally deal with the problem of pipeline regulation. Used in the pipeline on the axial length. To avoid exceeding the amount allowed on the road to set up guide bracket to avoid exceeding the amount allowed. The installation should be symmetrically and gradually pressurized and twisted to prevent leakage.Rubber expansion joints meet the requirements of the joining process in the production process. For the heat pipe network laid in the trench, when the pipeline topography is low, rainwater or accident wastewater will soak, should consider iron-nickel alloy, high nickel alloy and other corrosion-resistant materials. Due to the higher of such materials, in the manufacturing process, only a layer of corrosion-resistant alloy can be added to the surface in contact with corrosive media. Analysis of the types of failures and causes of fatigue life design shows that surface stability, axial stability and corrosion resistance are related to fatigue life.

Rubber expansion joints have good comprehensive type performance, so it is commonly used in chemical, construction, water supply, drainage, plumbing and other basic projects, and the installation of rubber expansion joints is prohibited. Axial displacement is lower than the pipeline support, otherwise anti-pulling equipment should be installed to avoid pressure at work. The pipe has fixed bracket or fixed bracket, and the fixed bracket is larger than axial. In the process of vertical installation and empty frame installation, the goods should be installed with corresponding fixed brackets and brackets to avoid falling off under the working pressure.