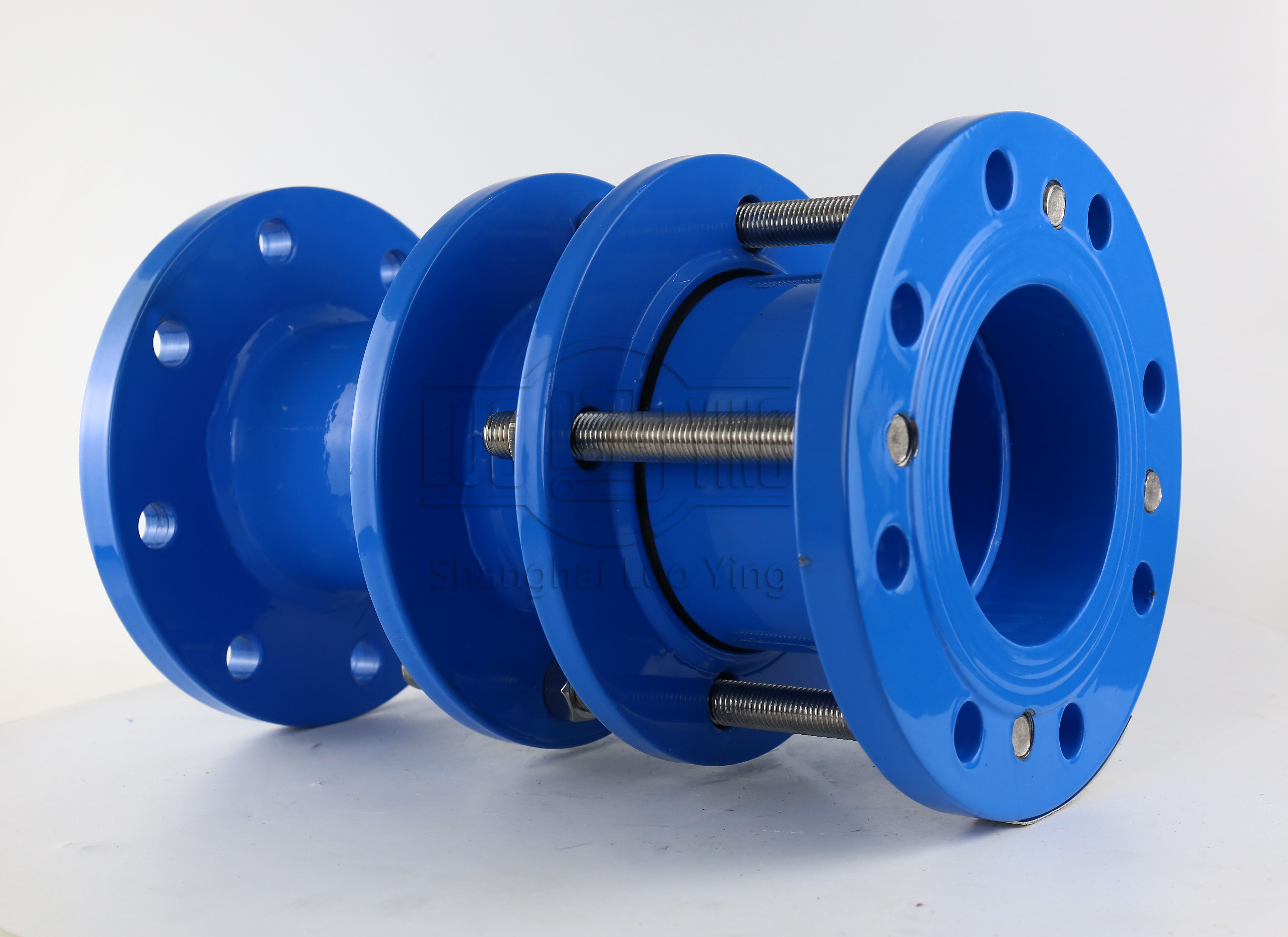

Double Flange Expansion JointsLearn more

Feb-23-15

The effect of nickel on the corrosion resistance performance of double flange expansion joints in various acid media, it should be noted that under some conditions in high temperature and high pressure water, the increase in the amount of nickel leads to an increase in the intergranular type stress corrosion sensitivity of pipes and alloys, but this unfavorable effect will be mitigated or subjected to due to the increase in the amount of chromium in pipes and alloys, with the increase in the amount of nickel in double flange expansion joints, the critical amount of carbon to produce intergranular corrosion decreases, the That is, the intergranular corrosion sensitivity of the pipeline increases, as to the performance of the double flange expansion joint resistance to pitting corrosion and crevice corrosion.Generally speaking, simple double flange expansion joints are only used in demanding and oxidation resistant media conditions of use, double flange expansion joints as an important alloying element in double flange expansion joints added to the pipeline to further expand its scope of application, the role of double flange expansion joints is mainly to improve the pipeline in reducing media than H2SO4, H3PO4, as well as some organic acids and urea environment corrosion resistance, and improve the pipeline's resistance to pitting corrosion and crevice corrosion. And to improve the performance of the pipeline resistance to pitting corrosion and crevice corrosion.

The oxidation effect on the double flange expansion joint is not significant, so when the double flange expansion joint maintains a single austenite organization and no intermetallic precipitation, the addition of double flange expansion joint has little effect on its room temperature mechanical properties, but as the amount of double flange expansion joint increases, the high temperature strength of the pipe increases.

Creep and other properties are greatly improved, so double flange expansion joint pipeline is often used in high temperature applications. The addition of double flange expansion joint makes the pipeline's high temperature deformation resistance increase, coupled with the presence of a small amount of δ ferrite in the pipeline, thus double flange expansion joint pipeline's thermal processability than not double flange expansion joint pipeline for