The rubber expansion joint installed at the pump outlet, the fittings should be complete so as not t

Feb-23-20

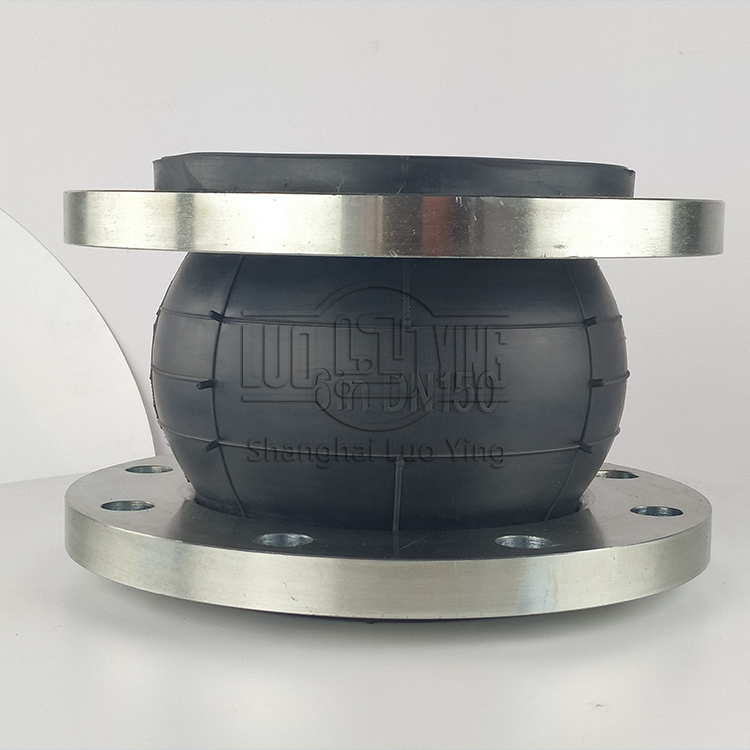

The structure of water pump rubber soft joint is very different from the general rubber expansion joint products. For general rubber expansion joint, it is equipped with anti-disengagement restriction protection device to ensure that the rubber expansion joint does not move when it works. Its installation length is longer than that of single-ball rubber expansion joint. This solves the problem of short installation length of rubber expansion joint.

Flexible rubber expansion joints can be bent. In this case, we need to synthesize rubber for customers according to the characteristics of rubber to achieve better results. Natural rubber is generally used for media such as drinking water pipes or pure water in factories. Due to its high content, the service life of natural rubber is longer than other rubbers. Natural rubber does not contaminate the medium. If it is a water plant, it is recommended to use rubber expansion joint. Customers choose the above two kinds of rubber according to their own situation. The product expands greatly and is easy and fast to install. It is suitable for connecting the pipes with flanges at both ends. The rubber expansion joint expander can compensate the axial displacement of the pipeline.

Why use rubber joints to connect sewage fire pumps? Due to the good overall performance of rubber expansion joints, they are mainly used for lifting and transporting raw water and sewage, water supply and cooling circulating water in thermal power plants, metallurgical industry, pipeline transportation of condensate and chemical substances. Cooling and dilution in the petroleum industry have flexible connections with long and short pipes in other industries.

Rubber expansion joints are mainly used for the pipeline transportation of cooling and circulating water of chemical raw materials, such as the lifting and transportation of raw water and sewage, thermal power plants, metallurgy, condensate and chemical materials, as well as the cooling and dilution of petrochemical industry, and the flexible connection of long and short pipes in other industries. Due to the high abrasion resistance of rubber, it is also suitable for all industrial granules, powders and low temperature steam transportation.

When installing the special rubber expansion joint inside the pump, the fittings should be complete and avoid contact with sharp metal instruments that could puncture the rubber ball of the pipe. For installation, tighten the bolts diagonally using flexible brackets. The pipeline pressure of the rubber flexible joint is too high, and the flanges at both ends should be connected with limit bolts. In civil construction, it is mainly used in pumping stations and pipelines for violent vibration.