Distinguish between internal defects and external connection failure of bendable rubber flexible joi

Feb-23-21

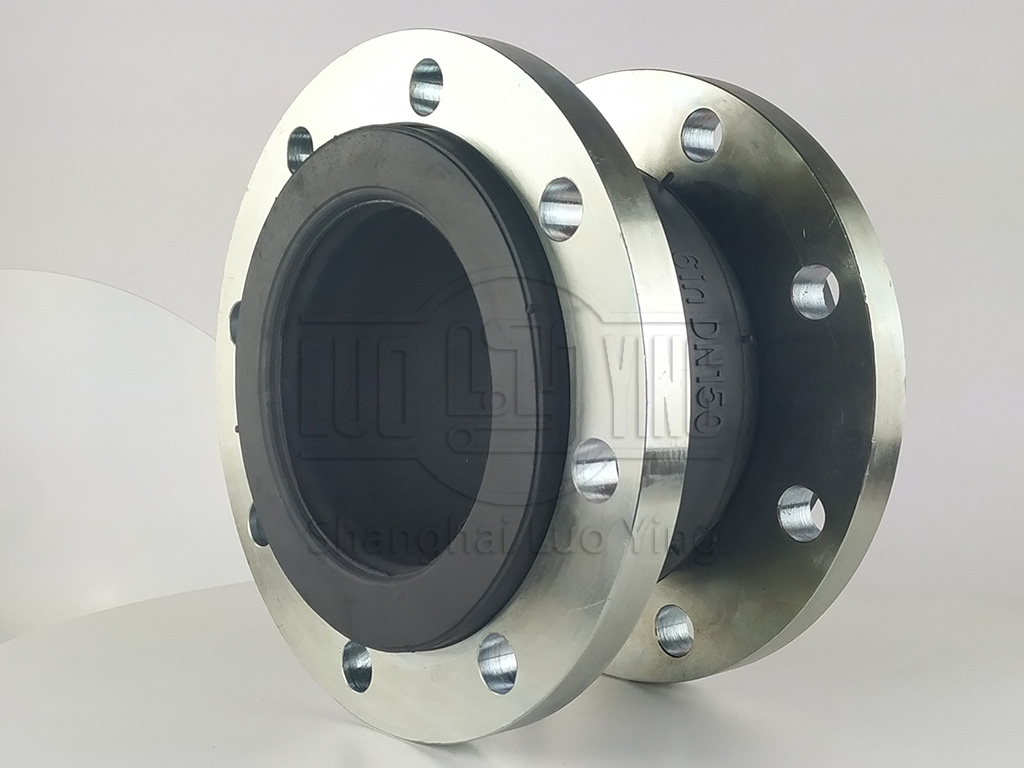

According to the time difference between the ultrasonic probe sending ultrasonic signal and the ultrasonic signal being reflected back, the ultrasonic probe is placed close to the outer surface of the rubber flexible connection and the ultrasonic signal is sent to the inside of the rubber flexible connection, so as to distinguish whether there is an internal defect detection of the rubber flexible connection. If there are defects on the surface of the rubber flexible connection, it is easy to find, but internal defects are difficult. The internal problem works on the principle of distinguishing internal structural defects of the pipeline rubber flexible connection based on the extraordinary data signal during partial discharge of the installation signal receiving probe, in fact, the abnormal data signal usually has a strong loss characteristic.If the bendable rubber flexible connection to withstand the pressure of the working capacity of the general, then when the working pressure of the pipe network increases, the rubber flexible connection will burst. Therefore, the rubber flexible connection must choose the national standard rubber flexible connection that can withstand pressure, work well, and have guaranteed quality. For everyone's natural environment, the total number of multi-story buildings is increasing. The heavier the working pressure provided at high altitude, the stronger the pressure-resistant working capacity of the pipeline. For example, if potable water has to be transported to a high-rise residence, then the higher the pressure resistance required for an overhead water pipe.

The solution after the failure of bendable rubber flexible joints: check the removal and replacement of parts with advantages and disadvantages. Check the flexural rubber soft joint rolling bearing slippery condition, give oil or remove and replace new oil. Open or lift the bendable rubber soft joint stuffing box cooling capacity. As the influence of external conditions is also the main element that causes equipment failure, so we need to have some strengthening in its corrosion resistance and other roles, in order to ensure more reliable application, we should try our best to enhance its reliability and improve its reliability to ensure.

Flexible rubber soft joint in the production and processing steps in the mold shell temperature control is also the key, first, the temperature of rubber and plastic products production and processing into the mold shell. Large-diameter bendable rubber flexible joints should be selected to separate temperature rise that can ensure that the temperature difference between the various parts of the rubber flexible joints the same, to ensure the quality of rubber flexible joints, bendable rubber flexible joints in the process of production is generally not easy to produce the surface out of the pore up the bag situation, the key factor that produces this condition is the semi-finished processing production and manufacturing condition of the internal gas without pressure squeeze, this type of situation requires attention to the rubber flexible joints This kind of situation needs to pay attention to the steps of production processing and molding of rubber flexible joints.