Pipeline metal corrugated compensator retrofitted with a guide tube requirements

Apr-23-24

Pipeline metal corrugated compensator retrofitted with a guide tube requirementsMetal corrugated compensator retrofitted guide tube on the pipeline medium and product installation location has requirements, incorrect random installation is the product and pipeline damage and loss, general media pipeline (dust, particles, soot) in order to avoid direct contact with the medium metal corrugated compensator stainless steel body, resulting in damage to the body of the tube affects the normal use, so the need to install a guide tube, not only can protect the product can also increase Metal corrugated compensator service life, and fire water supply pipeline is not required to add a guide tube, incorrect installation will lead to pipeline in the lateral displacement of the damage to the metal corrugated compensator, so the guide tube is based on the pipeline medium and installation environment to decide, can not blindly and arbitrarily add the metal corrugated compensator guide tube.

The occasion of using metal corrugated compensator, mainly using its elasticity or burned of course, will not use cast iron a class of brittle materials or hard state of the pipe, strip to make metal corrugated pipe. Although the theft of metal bellows with its diameter, corrugated geometry, material, state, wall thickness and other factors, precisely for the above reasons, in general can ignore the material, state, wall thickness and other aspects of the established factors, only from the diameter, corrugated geometry can be relatively accurate analysis of the deflection of the metal bellows compensator.

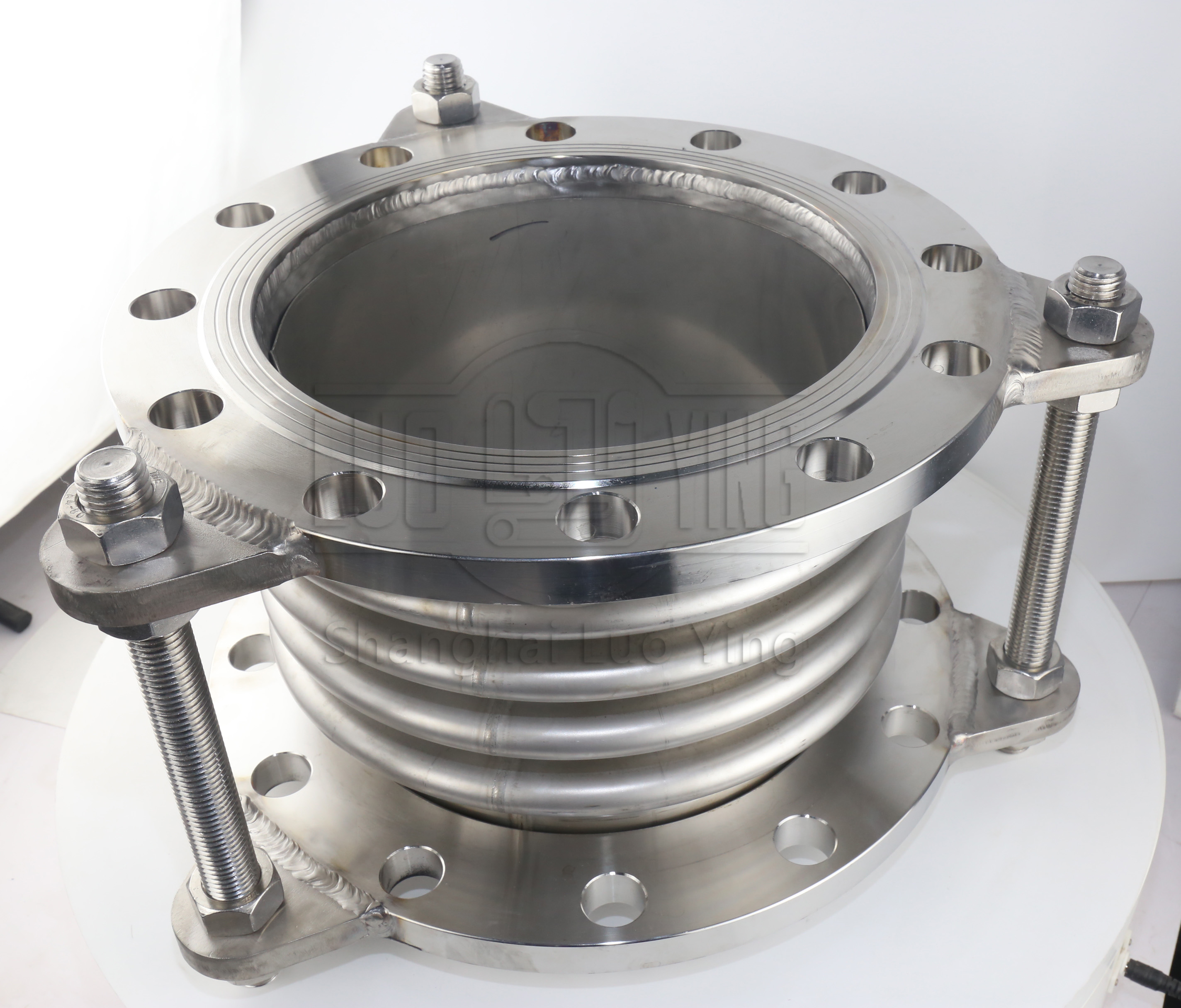

The corrugated metal compensator consists of a corrugated tube (an elastic element) that forms the main body of its work and accessories such as end tubes, brackets, flanges and conduits. Shrinkage is a flexible structure set on the vessel shell or pipe in order to compensate for the additional stress caused by temperature difference and mechanical vibration. Application of its work body bellows expansion and contraction deformation, to absorb the pipeline, conduit, containers, etc. from thermal expansion and contraction and other reasons resulting in size changes, or compensate for axial, lateral and angular displacement of pipelines, conduits, containers, etc. Corrugated shrinkage joints can also be used for noise reduction and vibration reduction, heating, in order to avoid heating pipeline heating, due to thermal elongation or temperature stress caused by pipeline deformation or destruction, the need to set up compensators on the pipeline In order to avoid the heating pipeline heating up, due to thermal elongation or temperature stress caused by pipeline deformation or destruction, the need to set up compensators on the pipeline to compensate for the thermal elongation of the pipeline, so as to reduce the stress on the pipe wall and the force acting on the valve or support structure.