Corrugated compensator in the hydraulic test what to pay attention to

Apr-23-29

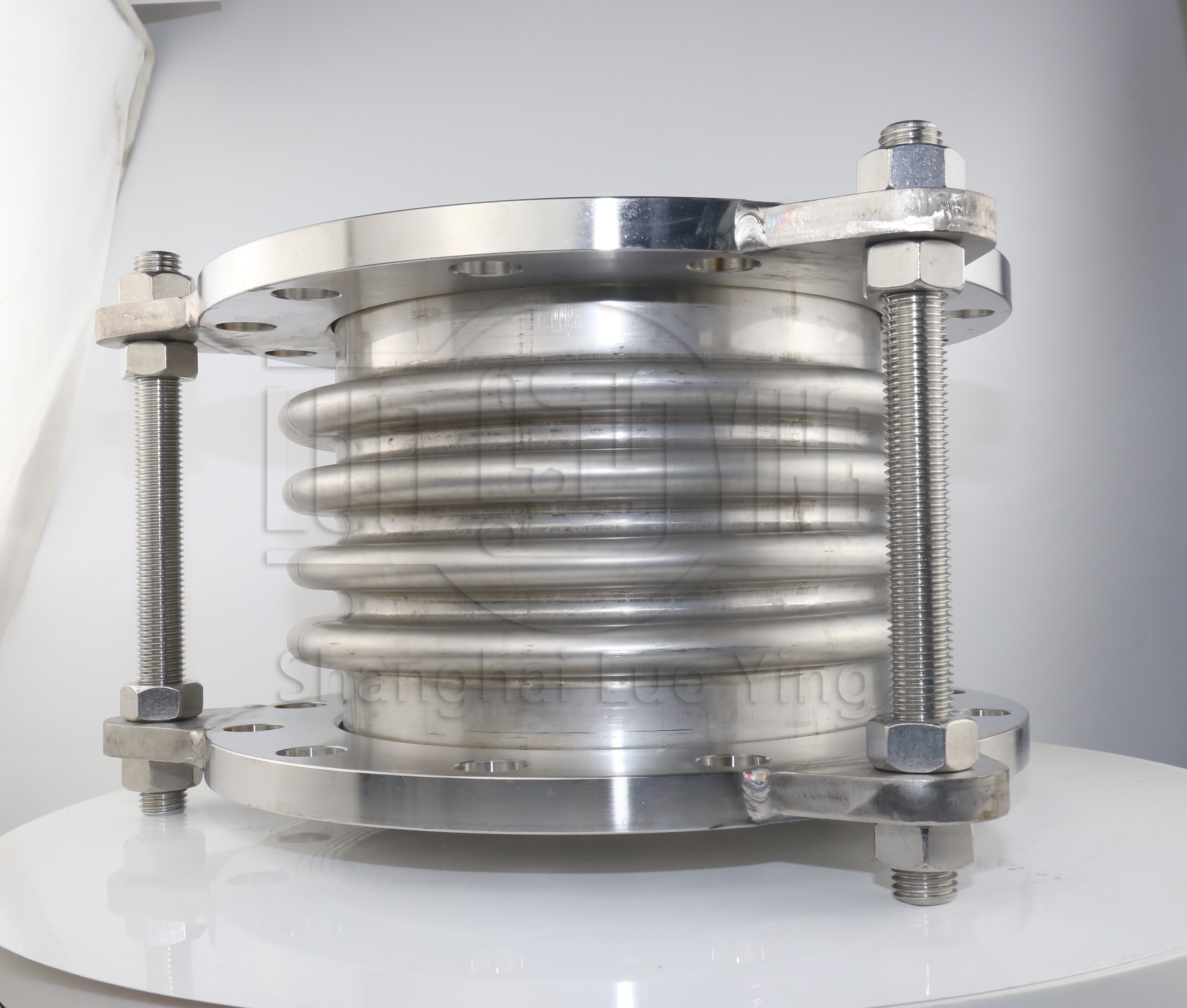

Corrugated compensator in the hydraulic test what to pay attention toCorrugated compensator is an important pipeline connection, mainly used to compensate the expansion and contraction of the pipeline when the temperature and pressure change, so as to ensure the safe operation of the pipeline. The corrugated compensator also plays an important role in the hydraulic test. The following are several aspects that need to be noted when using the corrugated compensator in the hydraulic test:

Pay attention to the installation position and quantity of the corrugated compensator. The installation position of the corrugated compensator should be at the bend of the pipeline or the connection between two sections of the pipeline, so that it can better meet the expansion and contraction needs of the pipeline. In addition, in the hydraulic test, it is also necessary to determine the number of corrugated compensators according to the length and diameter of the pipeline and other parameters to ensure the stability and safety of the pipeline during the test.

Pay attention to the material and difference of the corrugated compensator. During the hydraulic test, the pipeline is subjected to high pressure, so the material of the corrugated compensator must choose high-strength, corrosion-resistant materials, such as stainless steel, copper alloy, etc. In addition, if different specifications and materials of the corrugated compensator are installed in the same pipeline, then special attention needs to be paid to the differences of these corrugated compensators in the hydraulic test to avoid safety problems such as water leakage.

Pay attention to the sealing of the corrugated compensator. In the hydraulic test, the corrugated compensator is under great pressure, so the sealing of the corrugated compensator is very important. In the installation process, attention should be paid to the strength and sequence of tightening bolts to ensure that the connection between the corrugated compensator and the pipe is firm and not loose to ensure the safety of the test process.