How to use single sphere rubber joints correctly to extend their service life?

May-23-28

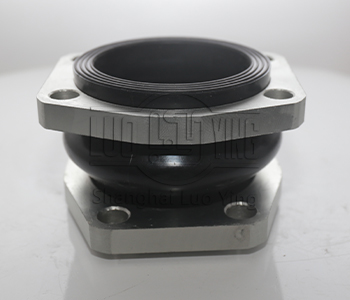

How to use single sphere rubber joints correctly to extend their service life?Single sphere rubber joints are commonly used in piping systems to absorb vibration, reduce noise, and compensate for thermal expansion and contraction. However, improper use and installation can lead to premature failure and reduced service life. In this article, we will discuss how to use single sphere rubber joints correctly to extend their service life.

1. Proper InstallationProper installation is critical to the performance and longevity of single sphere rubber joints. The joint should be installed in the correct orientation, with the flanges aligned and bolted securely. The joint should not be over-torqued, as this can damage the rubber and reduce its flexibility. It is also important to ensure that the joint is not twisted or kinked during installation, as this can cause stress on the rubber and lead to premature failure.

2 . Proper AlignmentProper alignment is essential to the performance of single sphere rubber joints. The piping system should be properly aligned and supported to prevent excessive stress on the joint. Misalignment can cause the joint to twist or bend, leading to premature failure. It is also important to ensure that the joint is not subjected to excessive axial or lateral movement, as this can cause stress on the rubber and reduce its flexibility.

3. Proper Operating ConditionsSingle sphere rubber joints are designed to operate within certain temperature and pressure ranges. It is important to ensure that the joint is not exposed to temperatures or pressures outside of its design limits, as this can cause the rubber to degrade and reduce its flexibility. It is also important to ensure that the joint is not exposed to corrosive or abrasive substances, as this can damage the rubber and reduce its service life.

4. Regular Inspection and MaintenanceRegular inspection and maintenance can help to extend the service life of single sphere rubber joints. The joint should be inspected periodically for signs of wear, damage, or degradation. Any issues should be addressed promptly to prevent further damage. It is also important to ensure that the joint is properly lubricated and cleaned to prevent buildup of debris or contaminants.

In conclusion, single sphere rubber joints are an important component of piping systems. By following proper installation, alignment, operating conditions, and regular inspection and maintenance, it is possible to extend the service life of these joints and ensure the safety and efficiency of the system.