What are the uses of monoflange force transfer joints

Jun-23-06

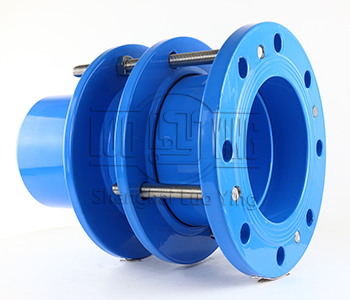

What are the uses of monoflange force transfer joints:Monoflange force transfer joint is mainly composed of flanged loose-fitting expansion joint, short pipe flange, force transfer screw and other components. It can not only transmit the pressure thrust of the connection (blind force) and the installation error of the compensator, but also cannot completely absorb the axial displacement. It is mainly used for the live sleeve connection of pump, valve and other components. The production of monoflanged force transfer joint strictly adopts high strength carbon steel or stainless steel and high quality rubber. Using the principle of rubber compression elastic deformation, it is sealed under the action of gland and bolt. The sealing ring is strictly selected according to the performance and user requirements...

Monoflanged force transfer joint is suitable for connection with flange on one side and welding with pipe on the other side. There is a certain gap between the body and the expansion pipe, so that it has a certain axial and radial displacement, which can effectively compensate and relieve the pressure in the pipeline. The thrust and blind of the pipeline also facilitate the installation, maintenance and replacement of pumps and valves. It is actually the most ideal supporting product for pipeline installation and operation industry.

Monoflanged force transfer joints are mainly suitable for connection with flange on one side and welding with flange on the other side. When installing, the installation length between both sides and the pipe needs to be adjusted. After the installation and welding is completed, the gland bolts are tightened diagonally so that it becomes a whole and has a certain amount of displacement for easy installation and maintenance. It can be adjusted according to the size, and axial thrust can be applied to each channel when working. The force transfer joint has a certain multi-directional displacement during the operation of the pipeline, which can not only reduce the blind thrust during the operation of the pipeline, but also play a certain protective role, especially suitable for the installation and maintenance of the pipeline. pipeline, but force transfer joints should be used at the outlet of the pump and at the corners of the pipeline, because the force transfer joints can also transfer the thrust of the blind plate when the pump is started to various parts of the pump and the pipeline through the force transfer bolts (i.e. all-thread bolts) to avoid the concentration of thrust on the pipeline or impact damage to the devices close to the pump.