Do different materials of rubber joints work differently?

Jun-23-08

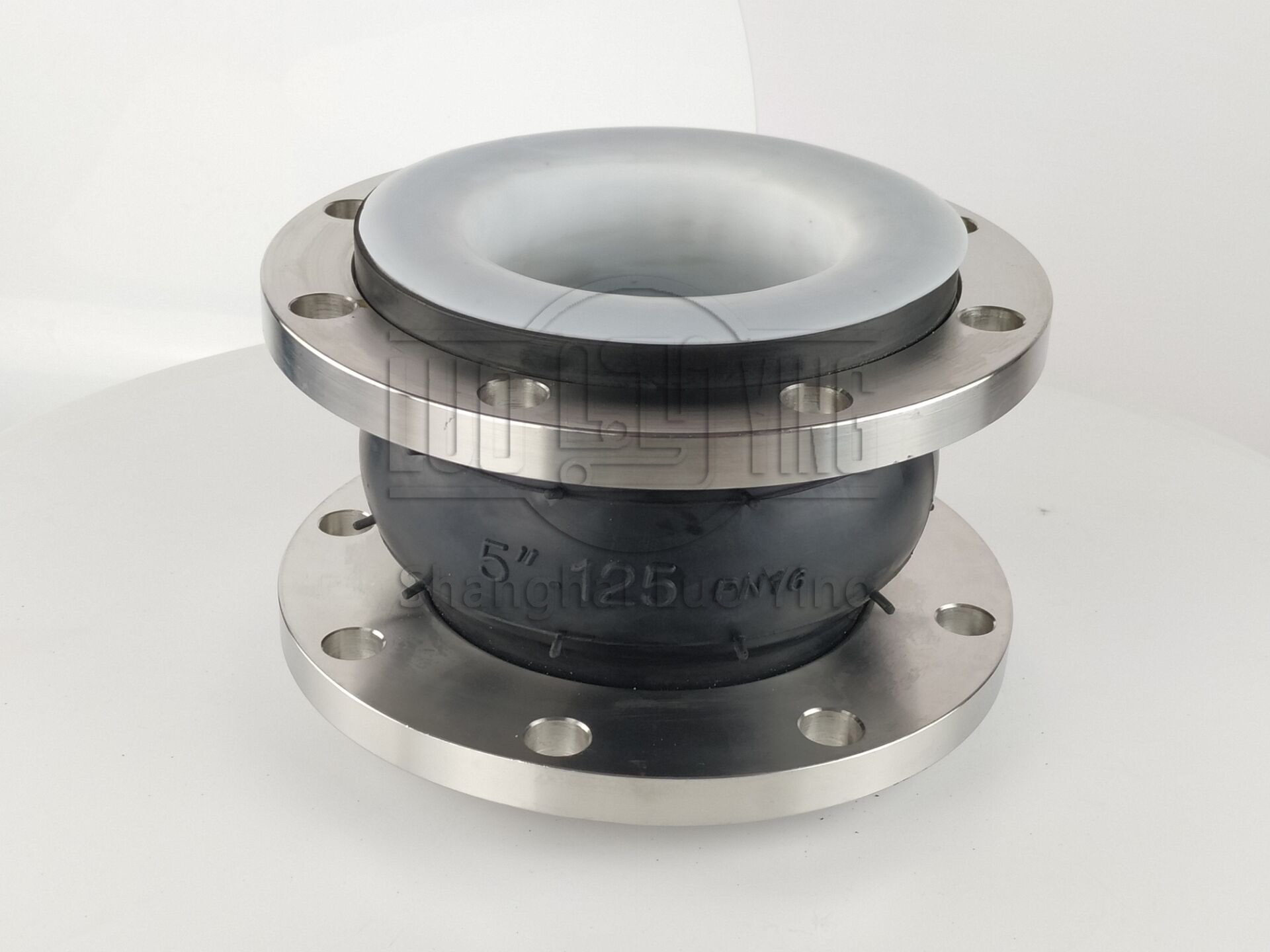

Do different materials of rubber joints work differently?Rubber joints are an important pipeline product, and their materials and working methods have an important influence on their performance and usage. According to different materials, rubber joints can have different working principles and uses.

In terms of material, rubber joints can be divided into three types: ordinary rubber joints, oil-resistant rubber joints and fluorine rubber joints. Common rubber joints are usually made of rubber, which has the advantage of being cheap and easy to manufacture and install, but its oil and temperature resistance is poor. Oil-resistant rubber joints are made of more durable vulcanized rubber, which has better oil resistance, but the cost is relatively high. Fluoroelastomer joints are made of fluoroelastomer, which has better resistance to oil, acid and high temperature, but they are more difficult to manufacture and install, and cost more.

In terms of working method, rubber joints can be divided into three parts: joint, receiver and connection. The joint is the two ends of the rubber joint, the receiver is the rubber joint connected to the pipe by means of connection, and the shape and size of the connection depends on the specific needs of the pipe.

The material and working way of rubber joints have an important influence on their performance and the way they are used. Choosing the right material and working way can make them better meet the needs of application scenarios and improve their efficiency and performance.