What factors determine the pressure resistance of corrugated compensators?

Jun-23-09

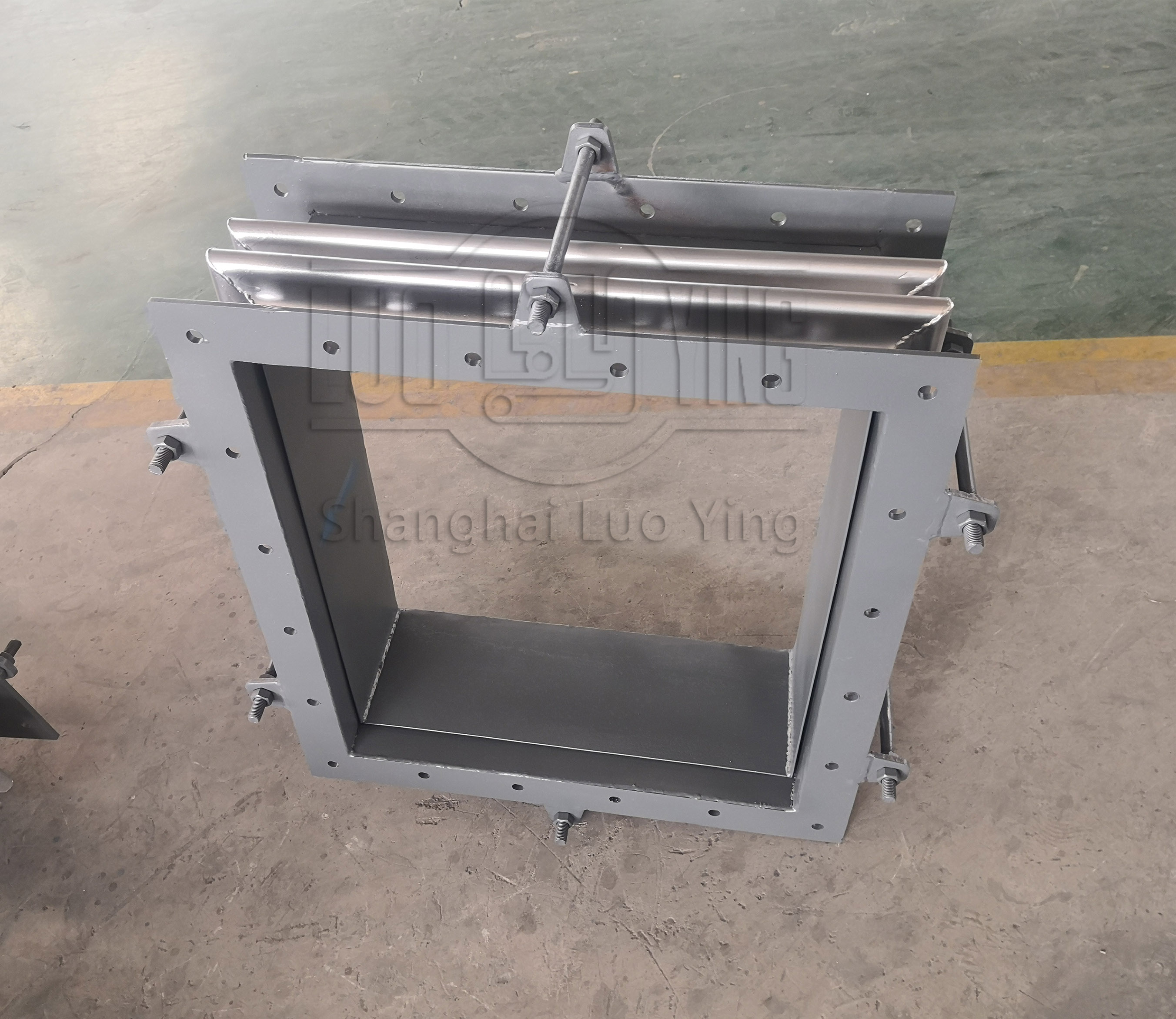

What factors determine the pressure resistance of corrugated compensators?One of the most important factors is probably the materials that the compensator is made from. It's important to use materials that can handle high-pressure systems and won't corrode or become damaged over time. Different materials will have different pressure ratings, so it's important to choose the right material for your particular application.

The design of the compensator is also important. Corrugated compensators are specifically designed to handle high-pressure situations, so their design is crucial. The geometry of the corrugations, the thickness of the walls, and other design factors can all impact the pressure resistance of the compensator.

The temperature and environment that the compensator is operating in can also play a role in its pressure resistance. High temperatures or harsh environments can cause damage to the compensator over time, so it's important to take those factors into account.

Overall, there are a lot of different factors that can impact the pressure resistance of corrugated compensators. The best way to ensure that you're using a compensator that can handle the pressure and environment of your specific application is to consult with an expert in the field. They can help you choose the right materials and design for your needs.