Points to note for the installation of rubber joints in and out of water pumps

Jun-23-15

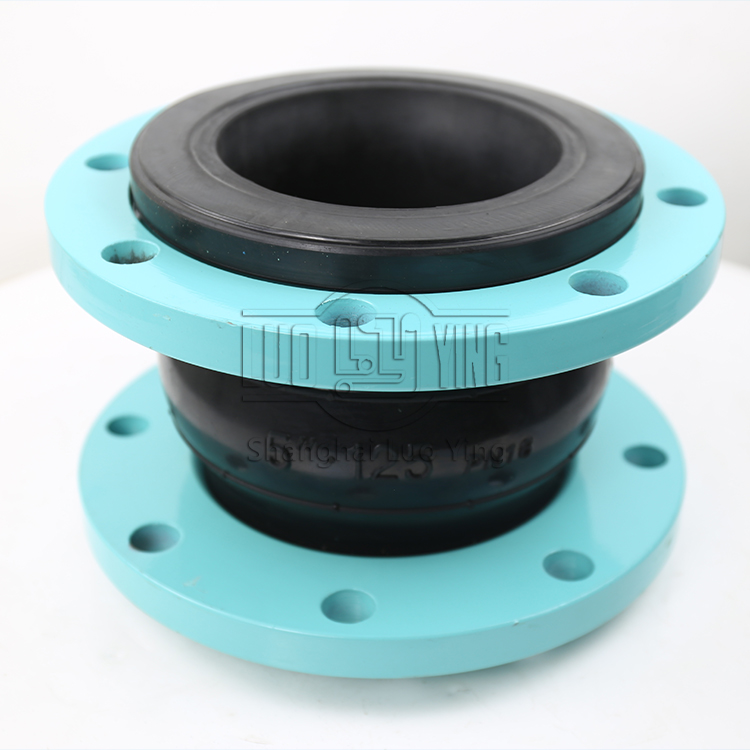

Points to note for the installation of rubber joints in and out of water pumpsThe rubber soft joint can be installed before and after the gate valve, which is for shock absorption, thermal expansion and contraction, and convenient disassembly and installation of the valve and maintenance.

1. Before installation, you must choose the right rubber soft joint model according to the working pressure of the pipeline, the linking method, the medium and the compensation amount, and the quantity should be chosen according to the requirements of noise reduction and displacement.

2. The normal applicable medium of rubber soft joints should be the ordinary medium whose temperature is 0-60℃. If you encounter special mediums such as oil, acid and alkali, high temperature and other corrosive mediums, you should choose the corresponding rubber soft joints.

3. If the rubber soft joint is installed at the outlet end of the pump, if no anti-pull-off and limit device is set, the pipeline system may sometimes shift the pipeline or equipment under the action of the blind force, and in serious cases, it may push the pump or pull the rubber soft joint out from the flange or pull the expansion joint apart, causing the water supply system to fail to work normally.

4. When installing rubber flexible joints, the screw of the bolt should be extended to the outside of the joint, and the bolt of each flange end face should be tightened evenly repeatedly according to the method of diagonal pressure to prevent pressure deviation. The screw joint should be tightened evenly with a standard wrench, not with a force-bearing rod to make the live joint slip, slide and break, and should be checked regularly to avoid loosening to cause dislodgement or water seepage.

When the displacement of the pipe is greater than or equal to the maximum compensation of the joint, the number of joints should be increased to parallel the displacement, and it is strictly forbidden to make the joint in the limit of the disturbance displacement and deviation in order to adjust the super difference of the pipe, not to mention the super limit (expansion, displacement, deflection, etc.), using the specific installation data in the following table.

6. Regular and timely maintenance of rubber joints should be carried out, for example, in the use or storage of rubber joints, high temperature, ozone, oil and acid-alkali environment should be avoided. At the same time, considering the aging problem of rubber products, it is necessary to build a shade frame in outdoor or sunny windward pipelines, and strictly prohibit exposure to sun, rain and wind.