What working conditions are wear-resistant rubber joints generally used in?

Jun-23-29

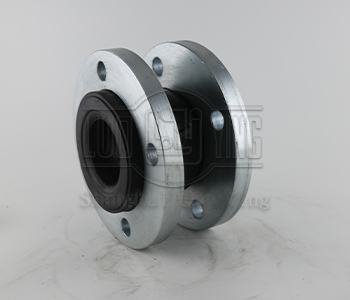

What working conditions are wear-resistant rubber joints generally used in?Abrasion resistant rubber joints are a kind of special working condition fittings, usually used for sealing and converting pipeline joints. The main purpose of the design and manufacture of this kind of joint is to ensure the smooth operation of the pipeline, reduce leakage and wear, and thus improve the service life of the pipeline.

Wear-resistant rubber joints are generally used in the following working conditions:

2. High-pressure working condition: When the medium is transported in the pipeline, the pressure of the medium will increase with the increase of height. Under this condition, the pipeline and the parts at the joint will be under greater pressure, so rubber joints with higher abrasion resistance are needed to protect the pipeline.

3. Low temperature working condition: In low temperature environment, the density of medium and the temperature of medium will be changed. Under such conditions, the pipeline and the parts at the joint will also suffer from different degrees of wear and tear, which requires the use of wear-resistant rubber joints with good low-temperature performance to ensure the service life of the pipeline.

The use of wear-resistant rubber joints depends on many factors, including the nature of the medium, the working pressure of the pipe and the operating altitude. Choosing the right wear-resistant rubber joint requires considering these factors and ensuring that the strength and sealing performance of the joint can meet the requirements of use.

In addition to ensuring the service life of the pipeline, wear-resistant rubber joints also need to have other functions, such as fittings in kind of special working conditions, usually used for sealing and conversion of pipeline joints. The main purpose of the design and manufacture of such joints is to ensure the smooth operation of the pipeline, reduce leakage and wear, and thus increase the service life of the pipeline.

Abrasion-resistant rubber joints can be used in a wide range of high-temperature, high-pressure and low-temperature environments and are a reliable solution for pipeline joints, significantly increasing the service life and reliability of the pipeline.