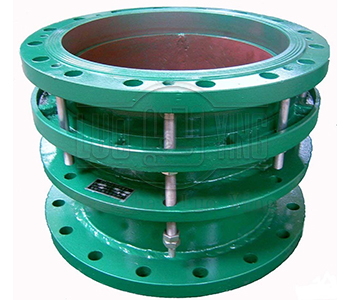

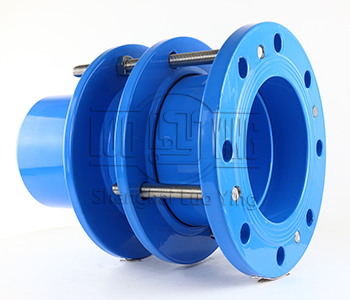

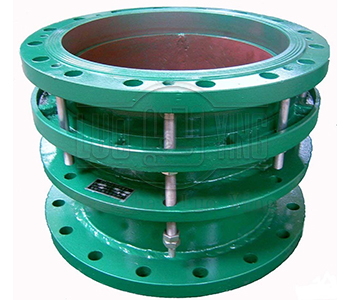

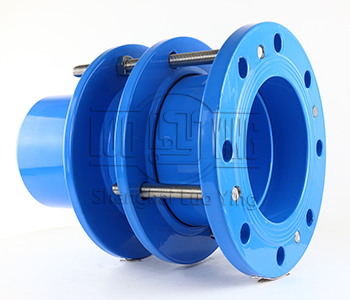

Limit Expansion Joints, Loose Sleeve Expansion Joints, Monoflanged Force Transmitting Joints

Jun-23-29

Limit Expansion Joints, Loose Sleeve Expansion Joints, Monoflanged Force Transmitting Joints

It is widely used in electric power, metallurgy, chemical industry, water supply and drainage, sewage treatment and other industries, mainly for the connection between water pump and valve and pipeline. It has an important role of expansion and contraction compensation.

In fact, in various pipelines, expansion joints, force joints, expansion joints (expansion joints) and rubber joints, clamp flexible joints (flexible clamp joints for short) and quick joints have a common role in pipeline connection, which plays a role in expansion and compensation displacement of pipeline operation. Because of their commonality in pipeline connections, they have a complementary and interchangeable alternative role in pipeline connections, and only in specific cases a certain type of series of pipe fittings is selected for use.

In the pump outlet and pipe corner, in the sliding pipeline connection without fixed piers, unlimited piers and directional limit piers brackets, force transfer joints and limit force transfer joints should be used, or limit expansion joints (expansion joints) and anti-pull-off limit rubber joints, as well as limit expansion joints and clamp flexible joints can be used, because force transfer joints through the force transfer bolt (i.e. full wire bolts) can be used to start the pump when the The blind thrust can be transferred to all parts of the pump and pipeline to avoid the thrust being concentrated at the corner of the pipeline or the near end of the pump, and the impact of the expansion joint can damage the equipment.

Note when connecting expansion joints and pipeline pipes: When welding expansion joints and pipeline pipes to connect, the concentricity of the equipment connected to each other or the quality of the weld seam inside and outside does not meet the requirements, after adjustment and re-welding or patch welding according to the welding connection requirements, there shall be no weld seam. When the spacing of pipe racks and piers is too large and the slope, the firmness of fixed pre-buried parts and the position of support, hanging and bracket do not match, they should be governed according to the relevant governance methods and requirements. Through the wall and floor at the vertical, horizontal pipe bending and horizontal pipe slope does not match, the pipe should be straightened; horizontal pipe slope governance should be used to pick the expansion of the wall hole, and adjust the distance size of the bracket to ensure that the slope of the pipe is correct.