How are pipeline transmission compensation joints selected, and how does it relate to hole size?

Jul-23-21

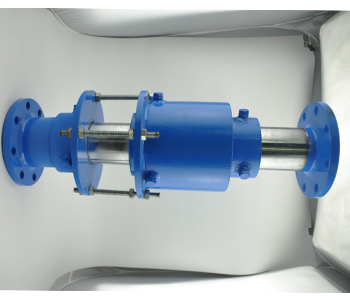

How are pipeline transmission compensation joints selected, and how does it relate to hole size?Pipeline transmission compensation joints are essential components in pipeline systems that help accommodate the thermal expansion and contraction of the pipelines. Selecting the appropriate compensation joints and considering the hole size in relation to them is crucial for the proper functioning and longevity of the pipeline system. This article will discuss the factors that influence the selection of compensation joints and how they relate to hole size.

When selecting pipeline transmission compensation joints, several factors need to be considered:

1 . Temperature range: The compensation joints must be able to withstand the temperature range of the pipeline system. The material used in the joints should have adequate thermal resistance and stability to prevent deformation or failure due to thermal expansion and contraction.

2 . Pipe material: The material of the pipeline itself affects the selection of compensation joints. Different pipe materials have different coefficients of thermal expansion, which will influence the amount of expansion and contraction that the joints need to accommodate. It is important to match the compensating capability of the joint to the expansion characteristics of the pipe material.

3 . Pipe diameter: The diameter of the pipeline is a critical factor in determining the type and size of the compensation joint. Larger diameter pipes tend to have higher expansion coefficients and greater thermal movement, requiring more substantial compensation joints.

4 . Movement capacity: The compensation joints should have sufficient movement capacity to accommodate the thermal expansion and contraction of the pipeline. The joint's design must allow for axial, lateral, angular, and torsional movement as per the requirements of the specific pipeline system.

5 . Design pressure and flow rate: Consider the design pressure and flow rate of the pipeline system. Compensation joints must be able to withstand the internal pressure while maintaining the required flow rate without causing excessive turbulence or pressure drop.

6 . Environmental factors: Environmental considerations such as exposure to corrosive chemicals, extreme weather conditions, and seismic activity should be taken into account. The compensation joint material should have the necessary corrosion resistance and durability to withstand these conditions.

The hole size, or the clearance between the compensation joint and the surrounding structure, is crucial for proper installation and operation. The hole size should allow for easy insertion and movement of the compensation joint while ensuring a secure and stable fit.

If the hole size is too small, it can restrict the movement of the compensation joint, leading to excessive stress on the joint or the surrounding structure. This can result in premature failure or deformation of the joint or damage to the pipeline system.

On the other hand, if the hole size is too large, it can compromise the stability and effectiveness of the joint. The joint may not be able to provide adequate support or fit securely in the opening, leading to leaks, vibrations, or misalignment.

Proper clearance should be provided between the compensation joint and the hole, considering the expansion and contraction movements of the pipeline. The clearance should allow for free movement without compromising the integrity or functionality of the joint.

In conclusion, selecting pipeline transmission compensation joints involves considering factors such as temperature range, pipe material, pipe diameter, movement capacity, design pressure, flow rate, and environmental conditions. The hole size in relation to the compensation joints is crucial and should be appropriately determined to ensure proper installation, movement allowance, and stability. By carefully considering these factors and maintaining the correct hole size, pipeline transmission compensation joints can effectively accommodate thermal expansion and contraction, ensuring the integrity and longevity of the pipeline system.