Essentials of Rectangular Natural Compensators in Wastewater Treatment.

Jul-23-22

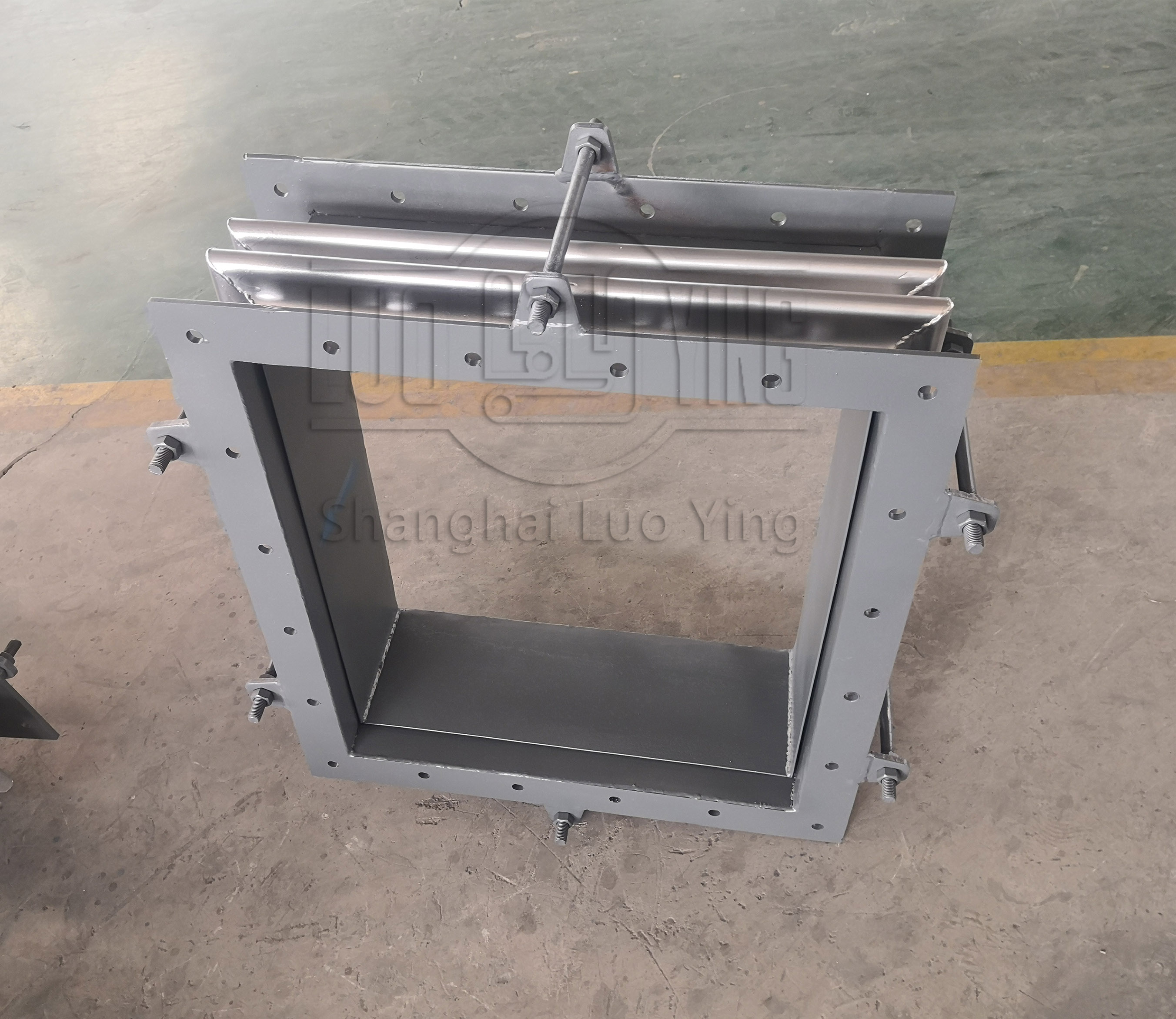

Essentials of Rectangular Natural Compensators in Wastewater Treatment. Rectangular natural compensators are essential components in wastewater treatment systems, specifically designed to accommodate the expansion and contraction of pipelines due to temperature fluctuations. These compensators play a crucial role in ensuring the integrity and efficiency of the entire wastewater treatment process. This article explores the key features and benefits of rectangular natural compensators in wastewater treatment.

Key Features:

Design and Structure: Rectangular natural compensators are designed as flexible joints with a rectangular shape, allowing for axial movement in one direction while restricting movement in other directions. They are typically made from rubber or elastomeric materials that can withstand harsh chemical environments commonly found in wastewater treatment facilities.

Temperature Compensation: Wastewater treatment processes often involve temperature changes, which can lead to thermal expansion and contraction of pipelines. Rectangular natural compensators are specifically designed to absorb these expansions and contractions, preventing stress and damage to the pipeline system.

Corrosion Resistance: To withstand the aggressive and corrosive nature of wastewater, rectangular natural compensators are constructed from materials that are resistant to chemical corrosion. This ensures their longevity and reliability in the wastewater treatment environment.

Benefits:

Stress Reduction and Pipe Protection: By accommodating thermal expansions and contractions, rectangular natural compensators reduce stress on the pipelines. This helps to prevent pipe failures and leaks, ensuring the overall integrity of the wastewater treatment system.

Enhanced Efficiency: The presence of rectangular natural compensators in wastewater treatment systems improves the overall efficiency by allowing for smooth and unrestricted movement of fluids through the pipelines. This optimizes the treatment process by minimizing pressure drops and energy losses.

Easy Installation and Maintenance: Rectangular natural compensators are relatively easy to install and maintain. They can be quickly integrated into existing pipeline systems, and their simple design allows for easy inspection and replacement if necessary.

Applications:

Rectangular natural compensators are widely used in various stages of wastewater treatment, including:

Inlet and Outlet Pipelines: These compensators are commonly installed at the entry and exit points of wastewater treatment plants to accommodate the temperature fluctuations in the incoming and outgoing wastewater.

Aeration Systems: Wastewater treatment often involves aeration processes to promote the growth of beneficial microorganisms. Rectangular natural compensators are used in aeration systems to allow for the expansion and contraction of pipelines associated with temperature changes.

Sludge Handling: Rectangular compensators can also be found in sludge handling systems where the transported sludge undergoes temperature variations. They accommodate the movement in the sludge pipelines, preventing stress on the system.

Effluent Discharge: In cases where the treated wastewater is discharged into a natural water body, rectangular compensators are used to compensate for any temperature fluctuations and subsequent expansions and contractions.

In conclusion, rectangular natural compensators are essential components in wastewater treatment systems, offering benefits such as stress reduction, pipe protection, increased lifespan, and enhanced efficiency. These compensators allow for the accommodation of thermal expansions and contractions, ensuring the integrity and reliability of the pipeline system. Given their wide range of applications, rectangular natural compensators play a vital role in optimizing the wastewater treatment process, contributing to the overall efficiency and sustainability of the facility.