VSSIA-2/B2F type double flange expansion joint installation preparation introduction.

Jul-23-26

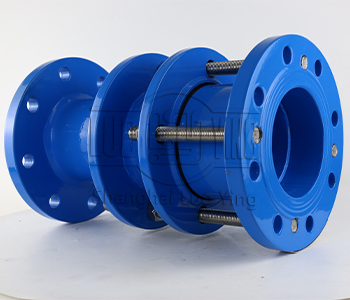

VSSIA-2/B2F type double flange expansion joint installation preparation introduction.Installing a VSSIA-2/B2F type double flange expansion joint requires careful preparation to ensure proper installation and optimal performance. This article provides an introduction to the installation preparation process for the VSSIA-2/B2F type double flange expansion joint.

Reviewing Manufacturer's Instructions: Before initiating the installation, carefully review the manufacturer's instructions provided with the expansion joint. These instructions will provide specific guidance on the installation process, including necessary tools, equipment, and safety precautions. Adhering to the manufacturer's instructions is crucial to ensure proper installation and avoid potential issues.

Gathering Required Tools and Equipment: Ensure that all the necessary tools and equipment are available before starting the installation process. Some common tools and equipment needed for VSSIA-2/B2F type double flange expansion joint installation may include wrenches, sockets, torque wrenches, gaskets, bolts, nuts, and sealants. Verify the sizes and quantities required for each component to avoid delays during the installation.

Inspecting the Expansion Joint: Thoroughly inspect the VSSIA-2/B2F type double flange expansion joint for any visible damage or defects. Check for tears, cuts, or signs of degradation in the rubber material. Ensure that the metallic components, including the flanges and reinforcement rings, are intact and free from corrosion or other damages. If any defects are noticed, contact the manufacturer for further guidance or obtain a replacement if necessary.

Preparing Gaskets and Bolts: Apply a thin layer of lubricant or sealant on the gaskets to ensure a proper seal during installation. Properly lubricate bolts and nuts to facilitate the tightening process. Make sure that the gaskets and bolts are of the correct size and type specified by the manufacturer. Follow the torque specifications provided by the manufacturer for proper bolt tightening.

Ensuring Proper Clearance: Check and ensure that there is sufficient clearance between the expansion joint and surrounding structures, such as walls, floors, or other piping. Adequate clearance is important to allow for the movement and expansion of the joint during operation. Take necessary measures, such as adjusting nearby structures or relocating the joint if needed, to maintain the required clearance.

Safety Precautions: Prioritize safety during the entire installation process. Ensure that all personnel involved are wearing appropriate personal protective equipment (PPE) and are aware of any specific safety requirements or precautions outlined by the manufacturer. Follow safe rigging and lifting practices when handling and positioning the expansion joint to avoid accidents or injuries.

In conclusion, the installation preparation process for the VSSIA-2/B2F type double flange expansion joint involves reviewing manufacturer's instructions, gathering necessary tools and equipment, checking flange alignment, inspecting the expansion joint for defects, preparing gaskets and bolts, ensuring proper clearance, and following safety precautions. By properly preparing for the installation, you can ensure a successful and efficient installation of the VSSIA-2/B2F type double flange expansion joint.