The construction and assembly process of steel carbon steel disassembly joints.

Jul-23-29

The construction and assembly process of steel carbon steel disassembly joints. Steel carbon steel disassembly joints play a significant role in industries such as oil and gas, chemical processing, and power generation. These joints are designed to allow for easy disassembly and reassembly of pipelines, equipment, or structures, enabling maintenance, repairs, or modifications to be carried out efficiently. In this article, we will explore the construction and assembly process of steel carbon steel disassembly joints.

Design and Specifications: The construction of steel carbon steel disassembly joints starts with the design and specification phase. Engineers analyze the requirements of the project and create detailed blueprints, considering factors such as pressure rating, temperature range, and the dimensions of the joint. The design also accounts for the specific type of media or fluids that the joint will handle.

Material Selection: Steel carbon steel is the primary material used in the construction of disassembly joints due to its strength and durability. Factors such as pressure, temperature, and corrosion resistance requirements influence the selection of the appropriate grade of carbon steel. The chosen material is thoroughly inspected to ensure its quality and compliance with industry standards.

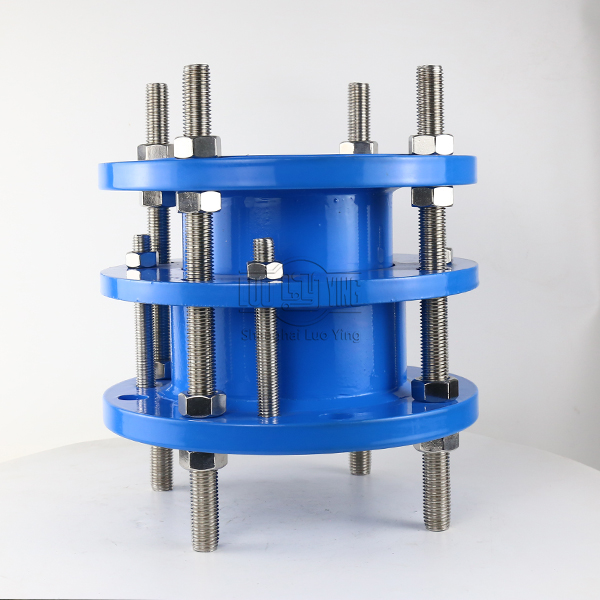

Manufacturing of Components: The construction process involves the manufacturing of the various components that constitute the disassembly joint. These components typically include flanges, gaskets, bolts, nuts, and other necessary fittings. CNC machines or forging techniques are commonly used to shape and form the components based on the design specifications and industry standards.

Surface Preparation: Prior to assembly, the surfaces of the components must be prepared to ensure proper sealing and integrity of the joint. Surface preparation techniques include cleaning, degreasing, and removing any rust or contaminants. This is crucial to achieve optimal adhesion and prevent leakage or corrosion over time.

Assembly: The assembly process involves the precise alignment and connection of the individual components to create the disassembly joint. Bolts, nuts, and gaskets are carefully fitted to provide a secure and leak-proof connection. Torque specifications are followed to ensure proper tightening of the bolts, providing the necessary clamping force for a reliable joint.

Quality Control: During and after assembly, strict quality control measures are implemented to ensure the construction of a high-quality joint. Visual inspections are conducted to identify any defects or irregularities in the components or the assembly process. Non-destructive testing methods such as ultrasonic testing or dye penetrant inspection may also be employed to detect any hidden flaws that could compromise the joint's performance.

Testing and Verification: Once the disassembly joint is assembled, it undergoes various tests to verify its performance and integrity. Pressure testing is typically conducted to ensure the joint can withstand the specified operating pressures without leaks. Other tests, such as vibration or temperature tests, may also be performed to validate the joint's reliability and durability under different operating conditions.

In conclusion, the construction and assembly process of steel carbon steel disassembly joints involves careful design, material selection, component manufacturing, surface preparation, assembly, quality control, testing, and installation. These joints provide a convenient solution for disassembling and reassembling pipelines, equipment, or structures, facilitating maintenance, repairs, or modifications in various industries. The construction process ensures that the joints meet industry standards, ensuring their reliability, durability, and safety.