Gland Type Limit Expansion Joints Adapt to Different Piping and Environmental Needs.

Jul-23-31

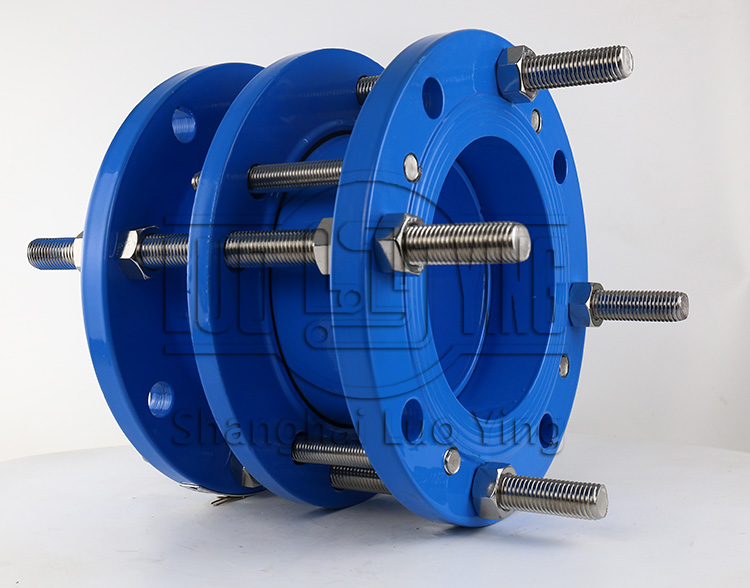

Gland Type Limit Expansion Joints Adapt to Different Piping and Environmental Needs.Gland type limit expansion joints are widely used in piping systems to accommodate thermal expansion, contraction, and vibration. These joints are designed with a gland structure that allows for controlled movement while maintaining a tight seal. In this essay, we will explore the adaptability of gland type limit expansion joints to different piping and environmental needs.

Piping Compatibility: Gland type limit expansion joints are highly adaptable to different types of piping materials, including steel, stainless steel, cast iron, ductile iron, PVC, and other thermoplastics. This versatility makes them suitable for a wide range of industries and applications. The joints can accommodate both standard and high-pressure piping systems, ensuring compatibility regardless of the specific requirements.

Expansion and Contraction: One of the key functions of gland type limit expansion joints is to absorb the thermal expansion and contraction that occurs in piping systems. These joints allow controlled movement in axial, lateral, and angular directions while maintaining a tight seal. By accommodating thermal movements, the joints prevent excessive stress on the piping system, reducing the risk of leaks, cracks, or structural failures.

Vibration Dampening: In addition to thermal expansion and contraction, gland type limit expansion joints are also effective in absorbing and dampening vibrations in the piping system. Vibrations can be caused by various factors such as equipment operation, fluid flow, and external forces. The design of the gland structure, along with the use of elastomeric materials, helps to mitigate these vibrations, preventing potential damage and enhancing system performance.

High-Pressure Applications: Gland type limit expansion joints can be designed and manufactured to withstand high-pressure applications, such as in oil and gas processing, power generation, and chemical industries. These joints are engineered to withstand the forces exerted by high-pressure fluids and maintain their integrity even under extreme conditions. Reinforced glands and specialized materials are used to ensure the joints can handle the pressure requirements of the specific application.

Compliance with Standards: Gland type limit expansion joints should meet industry standards and regulations to ensure their quality and safety. It is essential to select joints that comply with recognized standards such as ISO 9001 or ASME B31.3 to ensure that the products have been tested and proven to meet specific performance criteria.

In conclusion, gland type limit expansion joints provide adaptability to different piping and environmental needs. They are compatible with various piping materials, accommodate thermal expansion and contraction, dampen vibrations, resist corrosion, withstand high-pressure applications, and comply with relevant standards. By utilizing these versatile joints, piping systems can effectively address the challenges posed by thermal movement, vibrations, and environmental factors while maintaining integrity and performance.