Which aspects of expansion joints should be considered?

Aug-23-02

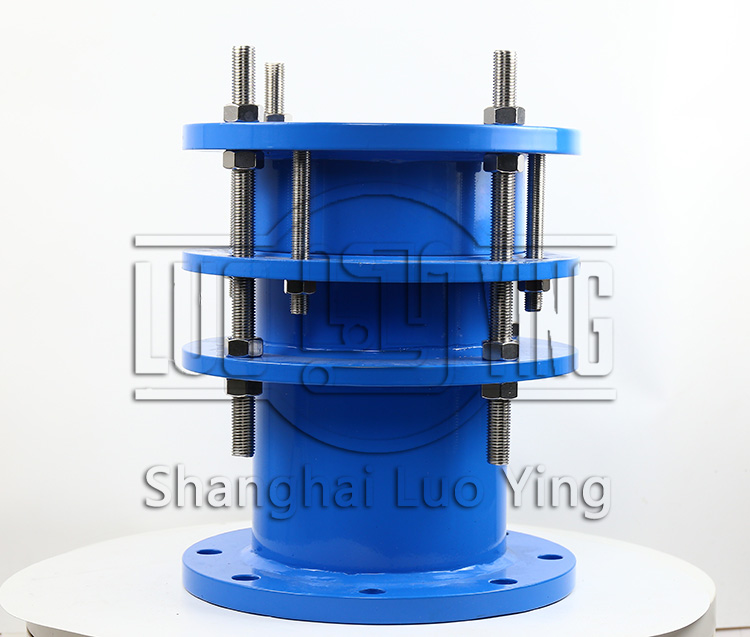

Which aspects of expansion joints should be considered?Expansion joints are crucial components in various industrial applications, designed to accommodate thermal expansion, vibration, and misalignment in piping systems. When considering expansion joints, several key aspects should be taken into account to ensure their proper functionality and effectiveness.

The first aspect to consider is the operating conditions and environment in which the expansion joint will be installed. Factors such as temperature, pressure, corrosiveness, and the type of fluid being conveyed must be carefully evaluated. These factors will determine the appropriate materials and design specifications required for the expansion joint to withstand the specific conditions it will be exposed to.

Furthermore, the size and dimensions of the expansion joint should be carefully considered. The expansion joint must be properly sized to accommodate the anticipated expansion and contraction of the piping system. Calculations based on factors such as pipe diameter, temperature differentials, and the thermal expansion coefficient of the materials involved can help determine the appropriate size and dimensions of the expansion joint.

The materials used in the construction of the expansion joint also play a significant role. Consideration should be given to the compatibility of the materials with the fluid being conveyed and the environment in which the expansion joint will be installed. Factors such as corrosion resistance, temperature resistance, and mechanical properties should be evaluated to select materials that will ensure the longevity and reliability of the expansion joint.

Additionally, the design and construction of the expansion joint should meet industry standards and specifications. Compliance with recognized codes, such as ASME, EJMA, or API standards, ensures that the expansion joint is manufactured and installed correctly. It is important to work with reputable manufacturers or suppliers that can provide documentation and certifications attesting to compliance with industry standards.

Maintenance and inspection considerations are also crucial. Regular inspections and maintenance procedures should be implemented to monitor the condition of the expansion joint and detect any signs of wear, corrosion, or damage. Proper maintenance practices can help extend the lifespan and performance of the expansion joint.

Lastly, cost considerations should be taken into account. While it is essential to select a high-quality expansion joint that meets all the necessary requirements, it is equally important to consider the overall cost-effectiveness. This includes not only the initial purchase cost but also factors such as installation, maintenance, and potential downtime costs.

In conclusion, the selection and consideration of aspects related to expansion joints are crucial for their proper functioning and longevity. Factors such as operating conditions, movement requirements, size, materials, compliance with standards, maintenance, and cost considerations should all be carefully evaluated to ensure the performance and reliability of the expansion joint in various industrial applications.