Pressure type corrugated compensator installation requirements.

Sep-23-05

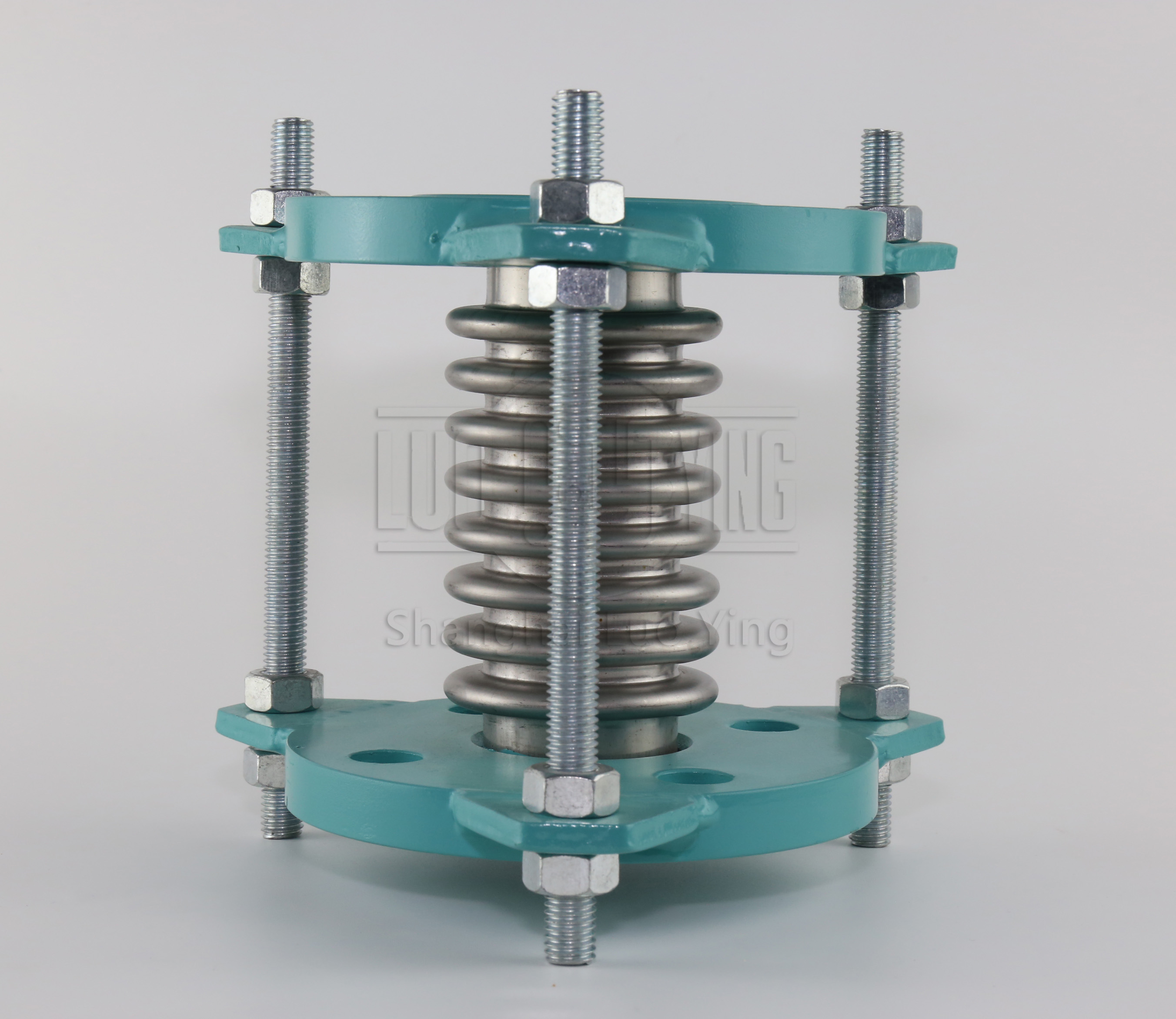

Pressure type corrugated compensator installation requirements.Pressure type corrugated compensators, also known as expansion joints, are vital components in many industrial systems. They are used to absorb thermal expansion, vibration, and movement in pipes, ducts, and other systems. Ensuring the proper installation of these compensators is crucial to their effectiveness and longevity. In this article, we will discuss some important installation requirements for pressure type corrugated compensators.

Proper Alignment: Before installing a compensator, it is important to ensure that the piping or ducting system is properly aligned. Misalignment can cause stress concentrations and reduce the compensator’s ability to absorb movement. The compensator should be installed in a straight section of the pipe or duct, with minimal bends or offsets.

Adequate Supports: Pressure type compensators must be properly supported to prevent excessive load on the bellows. Supporting the system properly ensures that the compensator can move freely and absorb the required movement. Supports should be installed close to each end of the compensator to prevent buckling or overstressing.

Correct Orientation: It is essential to install the compensator with the correct orientation for it to function properly. The arrow on the compensator indicates the flow direction, and it should be installed in the same direction as the flow of the media. Installing the compensator in the opposite direction can result in reduced performance and premature failure.

Proper Anchoring: While compensators are designed to absorb movement, they should not be relied upon as anchor points for the entire system. Adequate anchors should be installed on both sides of the compensator to prevent excessive movement. Anchoring the system properly helps to distribute forces and protects the compensator from overextension.

Correct Torque Application: When installing pressure type compensators, it is important to follow the manufacturer's recommendations for torque application. Over-tightening can cause damage to the bellows, while under-tightening can lead to leaks or premature failure. Use a torque wrench to apply the specified torque to the bolts or flanges.

Protection from External Factors: Pressure type compensators must be protected from external factors that can cause damage or reduced performance. This may include shielding the compensator from extreme temperatures, corrosive environments, or physical damage. Take necessary precautions based on the specific requirements of the system and the media being transported.

In conclusion, the proper installation of pressure type corrugated compensators is essential for their effective functioning and longevity. Factors such as alignment, supports, orientation, anchoring, torque application, protection from external factors, and regular inspection should be considered during the installation process. It is important to follow the manufacturer's guidelines and recommendations to ensure the optimal performance and reliability of the compensator.