What Rubber Joints for Drinking Water Transportation?

Sep-23-07

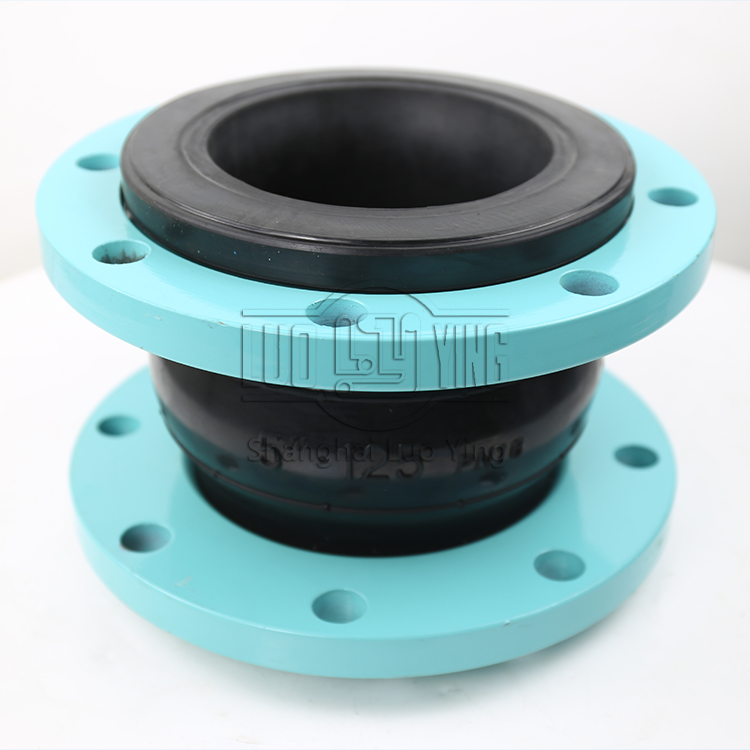

What Rubber Joints for Drinking Water Transportation?When it comes to drinking water transportation, selecting the right rubber joints is crucial to ensure the safety and efficiency of the system. In this article, we will discuss the types of rubber joints that are suitable for drinking water transportation and the factors to consider when making the selection.

NSF/ANSI Standard 61 Compliance: NSF/ANSI Standard 61 is the recognized standard for evaluating the safety of materials and products used in drinking water systems. When selecting rubber joints for drinking water transportation, it is essential to choose products that comply with this standard. NSF/ANSI 61 certified rubber joints ensure that they do not leach harmful substances or contaminants into the drinking water.

Material Compatibility: Rubber joints for drinking water transportation should be made from materials that are compatible with water and do not react or degrade when in contact with it. Common materials used for rubber joints in drinking water applications include EPDM (Ethylene Propylene Diene Monomer), Nitrile, Neoprene, and Natural Rubber. The material selection should consider factors such as temperature, pressure, and the presence of chemicals in the water.

Temperature and Pressure Ratings: Consider the temperature and pressure conditions that the rubber joints will be exposed to. Rubber joints should be capable of withstanding the maximum temperature and pressure levels in the drinking water system without experiencing deformation, leakage, or failure. It is essential to check the manufacturer's specifications to ensure that the selected rubber joints are rated for the intended operating conditions.

Flexibility and Movement Absorption: Rubber joints are used in drinking water transportation systems to absorb vibrations, noise, and movement. They should have excellent flexibility to accommodate the expansion, contraction, and lateral movements of the pipes. The rubber joints should be capable of absorbing angular, axial, and lateral movements in the system without inducing excessive stress or fatigue.

Installation and Maintenance: Consider the ease of installation and maintenance when selecting rubber joints for drinking water transportation. Rubber joints that are designed for easy installation and require minimal maintenance can save time and effort during system installation and routine maintenance.

In conclusion, selecting the right rubber joints for drinking water transportation is crucial to ensure the safety and reliability of the system. To make an informed decision, it is important to consider factors such as NSF/ANSI Standard 61 compliance, material compatibility, temperature, and pressure ratings, flexibility, longevity, and ease of installation and maintenance. By considering these factors, engineers and system designers can choose rubber joints that meet the specific requirements of drinking water transportation systems while ensuring water safety and operational efficiency.