Advantages of PTFE Lined Corrugated Compensators.

Sep-23-28

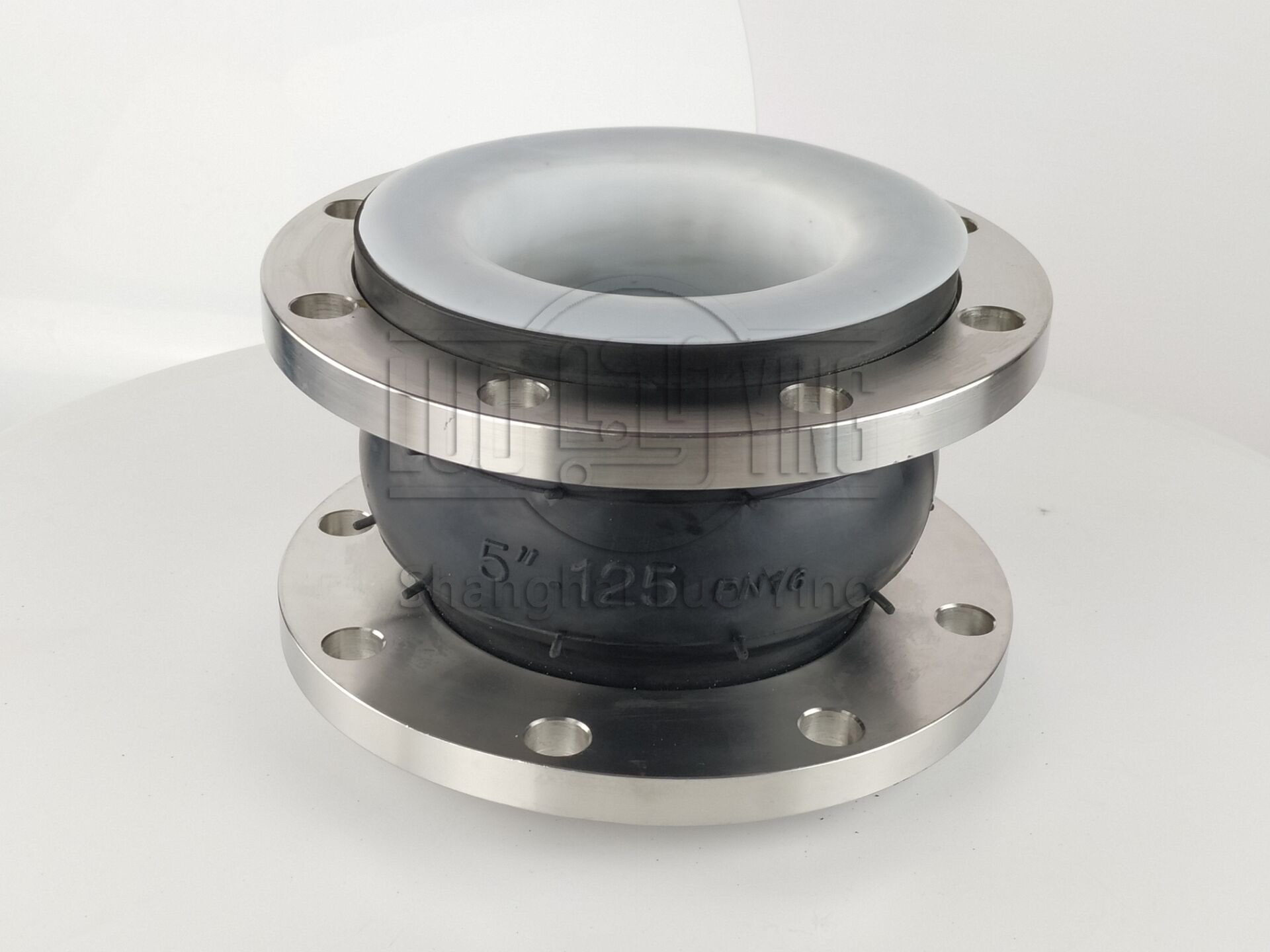

Advantages of PTFE Lined Corrugated Compensators. PTFE lined corrugated compensators, also known as PTFE lined expansion joints, offer a range of advantages in various industrial applications. In this article, we will explore the advantages of using PTFE lined corrugated compensators for pump and valve fittings.

First and foremost, the PTFE lining in these compensators provides exceptional chemical resistance. PTFE, or polytetrafluoroethylene, is known for its resistance to a wide range of corrosive chemicals, acids, and bases. By lining the inner surface of the compensator with PTFE, it creates a barrier that protects the metal bellows or corrugations from exposure to aggressive media. This makes PTFE lined corrugated compensators an ideal choice for applications that involve the handling of corrosive fluids or chemicals, ensuring long-term reliability and minimizing the risk of equipment failure.

Another advantage of PTFE lined corrugated compensators is their high-temperature resistance. PTFE can withstand temperature extremes ranging from cryogenic temperatures up to 260°C (500°F) without any significant loss in performance. This makes PTFE lined compensators suitable for use in high-temperature applications such as steam systems, thermal oil systems, or other processes that involve elevated temperatures. The ability to withstand extreme temperatures ensures that the compensators maintain their integrity and flexibility, avoiding any potential damage or failure due to thermal expansion and contraction.

Additionally, PTFE lined corrugated compensators provide excellent resistance to friction and wear. The smooth PTFE lining reduces friction between the compensator and the medium flowing through it, minimizing the risk of abrasion or damage to the inner surface. This is particularly beneficial in applications with high flow velocities or the presence of abrasive particles in the media being transported. The reduced friction also helps to maintain the overall efficiency of the system while extending the lifespan of the compensators.

PTFE lined corrugated compensators also exhibit excellent flexibility and movement absorption capabilities. The corrugated design allows for axial, lateral, and angular movements, accommodating thermal expansion, vibration, and misalignment in the pipeline system. This flexibility helps to reduce stress on pump and valve fittings, thereby extending their lifespan and minimizing the need for repairs or replacements.

Lastly, PTFE lined corrugated compensators offer easy installation and maintenance. Their lightweight construction and flexible design simplify the installation process, saving time and labor costs. Additionally, PTFE lining requires minimal maintenance, as it is resistant to fouling, scaling, and build-up commonly seen in other materials. This reduces the need for frequent cleaning or maintenance activities, resulting in lower maintenance costs and increased operational efficiency.

In conclusion, PTFE lined corrugated compensators provide several advantages for pump and valve fittings. Their exceptional chemical resistance, high-temperature resistance, low friction, flexibility, and ease of installation and maintenance make them a reliable and cost-effective choice. By incorporating PTFE lined corrugated compensators into industrial systems, operators can benefit from enhanced durability, reduced downtime, and improved performance.