Application of Teflon Lined Rubber Joints for Chemical Pipelines.

Nov-23-14

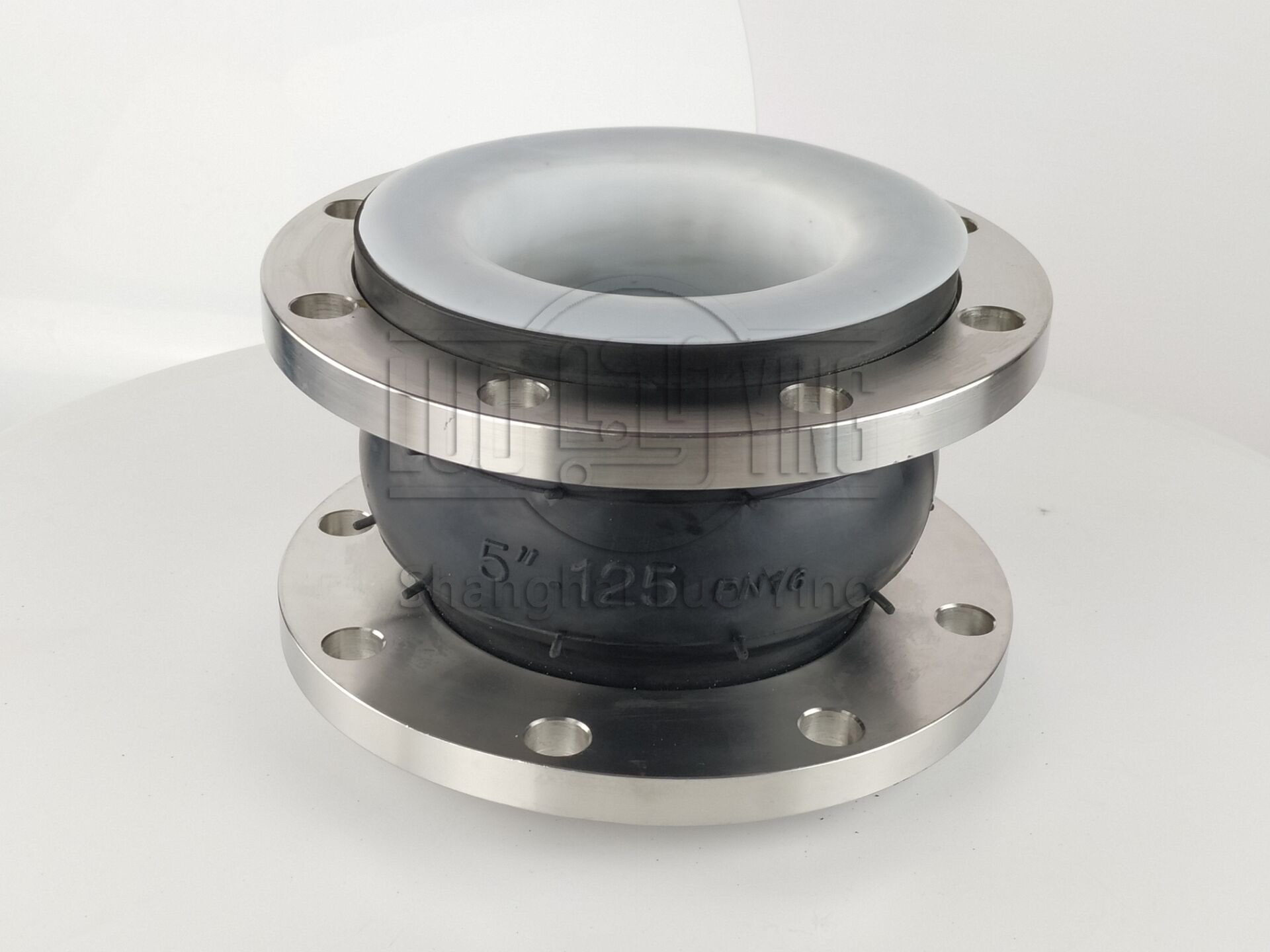

Application of Teflon Lined Rubber Joints for Chemical Pipelines. Teflon lined rubber joints are widely used in chemical pipelines due to their excellent chemical and durability. In this article, we will discuss the application of Tef lined rubber joints and their advantages in chemical pipelines.

Chemical pipelines often transport corrosive and aggressive fluids that can cause damage to conventional rubber joints. Teflon lined rubber joints offer a solution to this problem by providing a protective lining made of PTFE (polytetrafluoroethylene), which is resistant to a wide range of chemicals and solvents. The PTFE lining acts as a barrier, preventing direct contact between the fluid and the rubber material, thus protecting the joint from chemical attack.

One of the key advantages of using Teflon lined rubber joints in chemical pipelines is their superior chemical resistance. PTFE is known for its non-reactivity with most chemicals, acids, and solvents, making it an ideal choice for applications involving corrosive fluids. The PTFE lining prevents the fluid from permeating into the rubber material, ensuring the longevity and integrity of the joint.

In addition to their chemical resistance and flexibility, Teflon lined rubber joints also offer good resistance to high temperatures. PTFE has a high melting point and can withstand temperatures up to 260°C (500°F) without degrading. This makes Teflon lined rubber joints suitable for applications where high operating temperatures are involved.

The durability of Teflon lined rubber joints is another benefit that makes them ideal for chemical pipelines. The combination of the resilient rubber material and the chemically inert PTFE lining ensures that the joint can withstand the harsh conditions and corrosive fluids often encountered in chemical processing plants. This durability reduces the need for frequent maintenance and replacement, resulting in cost savings for the pipeline operators.

In conclusion, Teflon lined rubber joints are widely used in chemical pipelines due to their excellent chemical resistance, flexibility, and durability. The PTFE lining provides a protective barrier against corrosive fluids, while the rubber material offers flexibility and vibration absorption. The high temperature resistance and durability of these joints make them a reliable choice for chemical processing plants. By using Teflon lined rubber joints, pipeline operators can ensure the integrity and longevity of their systems while minimizing the risk of chemical leaks and failures.