How much do you know about the maintenance of single sphere rubber soft joint?

Sep-22-09

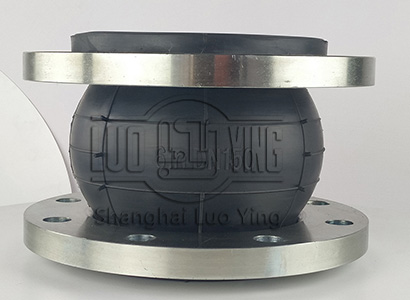

Rubber joints are mainly used for pipelines to reduce vibration, reduce noise, good expansion and contraction, and easy to use. Single sphere rubber joint, also called rubber soft joint, soft joint, vibration damper, pipeline shock absorber, etc., is a kind of pipeline joint with high elasticity, high airtightness, medium resistance and weather resistance. The product makes use of the elasticity, high air tightness, medium resistance, weather resistance and radiation resistance of rubber, etc. It is made of high strength, cold and heat stable polyester cord fabric twill intersection and its compound, and then vulcanized by high pressure and high temperature mold. In the actual installation process, in order to extend the product's ability to use, do a good job of rubber joint installation, so that rubber joints have a longer service life.1. To choose the right medium for the use of rubber joints.

If the normal applicable medium of rubber joints is ordinary water with temperature 0-60℃, special media such as oil, acid and alkali, high temperature and other corrosive and hard texture should be selected to use the corresponding special resistant material rubber joints, not to be blindly used in series or general.

2. Formal and accurate installation.

When the pipeline displacement is greater than or equal to the large compensation amount of the joint, the number of joints should be increased to parallel the displacement amount, and it is strictly forbidden to make the joint in the flexural displacement and deviation state in order to adjust the super difference of the pipeline, not to mention the super limit expansion, displacement, deflection, etc.

3. Installation at high altitude is to be noted.

For high-rise water supply or overhead water supply, the pipe should be fixed on a hanger, bracket or anchor frame, and the joint should not be allowed to bear the pipe's own weight and axial force, otherwise the joint should be equipped with an anti-pull-off device. When installing the single sphere rubber flexible joint, the screw of the bolt should be extended to the outside of the joint, and the bolt of each piece of flange end face should be tightened evenly repeatedly according to the method of diagonal pressure to prevent pressure deviation. The fillet joint should be tightened evenly with a standard wrench, do not add force with the force stalks to make the live joint slip silk, slip prongs and break, and it should be checked periodically to avoid loosening to cause dislodgement or water seepage.

4. Operation and maintenance.

The single sphere rubber soft joint should be re-pressurized and tightened before it is put into operation again after the first time to bear the pressure or before it is put out of use for a long time.

5. Post-protection treatment.

When using or storing rubber joints, avoid high temperature, ozone oil and acid-alkali environment. The pipeline used outdoors or facing the sun and the wind should be built with a shade frame, and the sun screen, rain and wind are strictly prohibited. Painting and winding insulation materials are strictly prohibited on the surface of joints. Because of the aging problem of rubber products, should be timely inspection and replacement.