What are the tips for shock absorber maintenance?

Sep-22-16

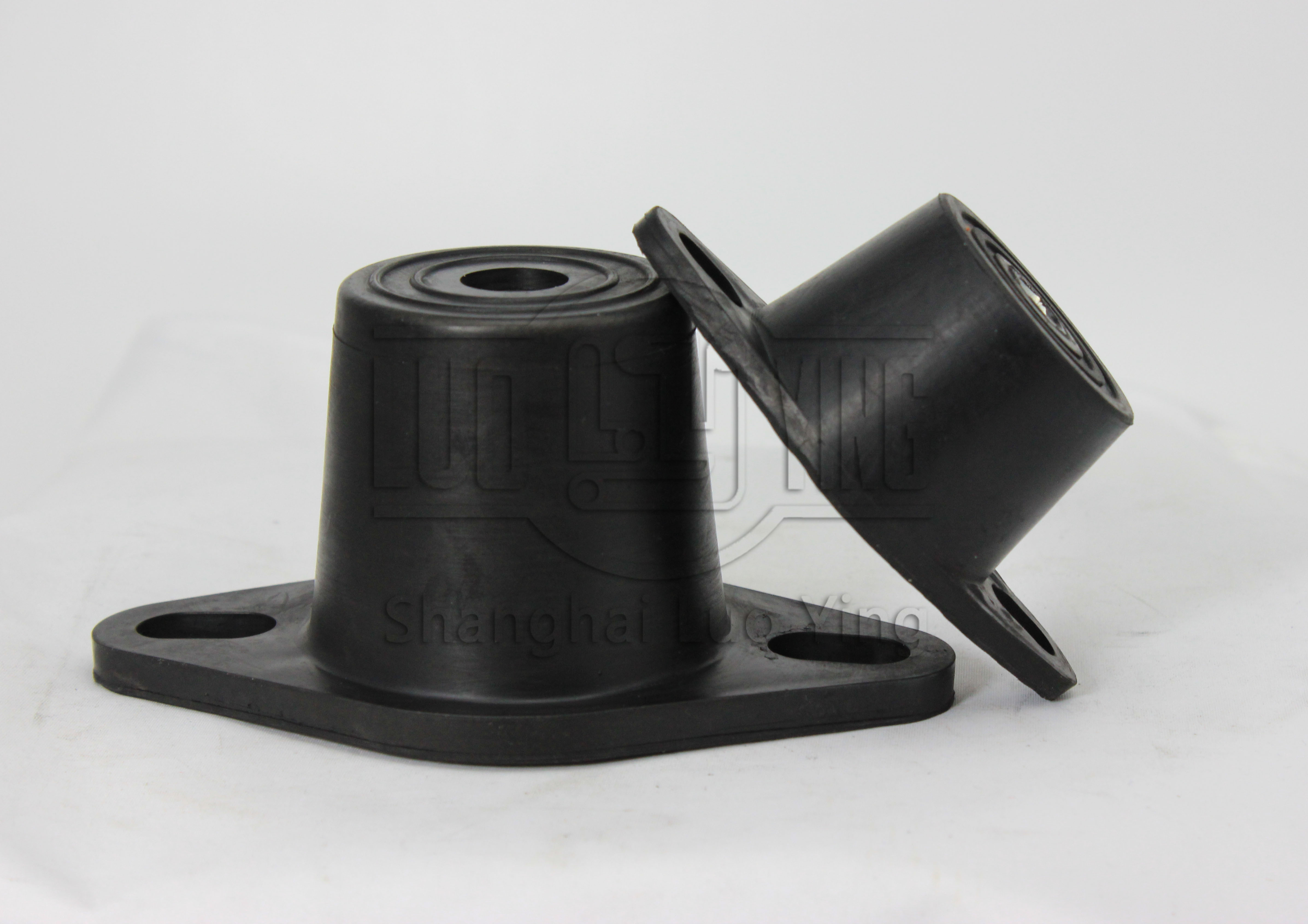

After determining that there is a problem or failure of the shock absorber, you should first check whether the shock absorber is leaking oil or has traces of stale oil leakage. The oil seal gasket and sealing gasket are broken and damaged, and the storage cylinder cover nut is loose.If oil leakage is found, first tighten the cylinder cover nut, if the shock absorber still leaks oil, it may be the oil seal, sealing gasket damage failure, should be replaced with a new seal. If still can not eliminate the oil leakage, should pull out the shock rod, if you feel a hair card or light weight is not a moment, and then further check whether the clearance between the piston and cylinder barrel is too large, the shock absorber piston connecting rod has no bending, the piston connecting rod surface and cylinder barrel whether there are scratches or strains.

If the shock absorber does not have the phenomenon of oil leakage, it should check whether the shock absorber connecting pin, connecting rod, connecting hole, rubber bushing, etc. are damaged, desoldered, broken or fallen off. If the above check is normal, the shock absorber should be further decomposed, check whether the clearance between the piston and cylinder is too large, whether the cylinder is strained, whether the valve seal is good, whether the valve flap and valve seat fit tightly, and whether the extension spring of the shock absorber is too soft or broken, according to the situation to take the repair of grinding or replacement parts to repair.

In addition, the shock absorber in the actual use of the sound of failure, which is mainly due to the shock absorber and steel plate spring, frame or shaft collision, rubber gasket damage or fall off, as well as the deformation of the shock absorber dust cylinder, insufficient oil and other reasons, should identify the causes, be repaired.