Which causes the rubber expansion joint damage?

Sep-22-24

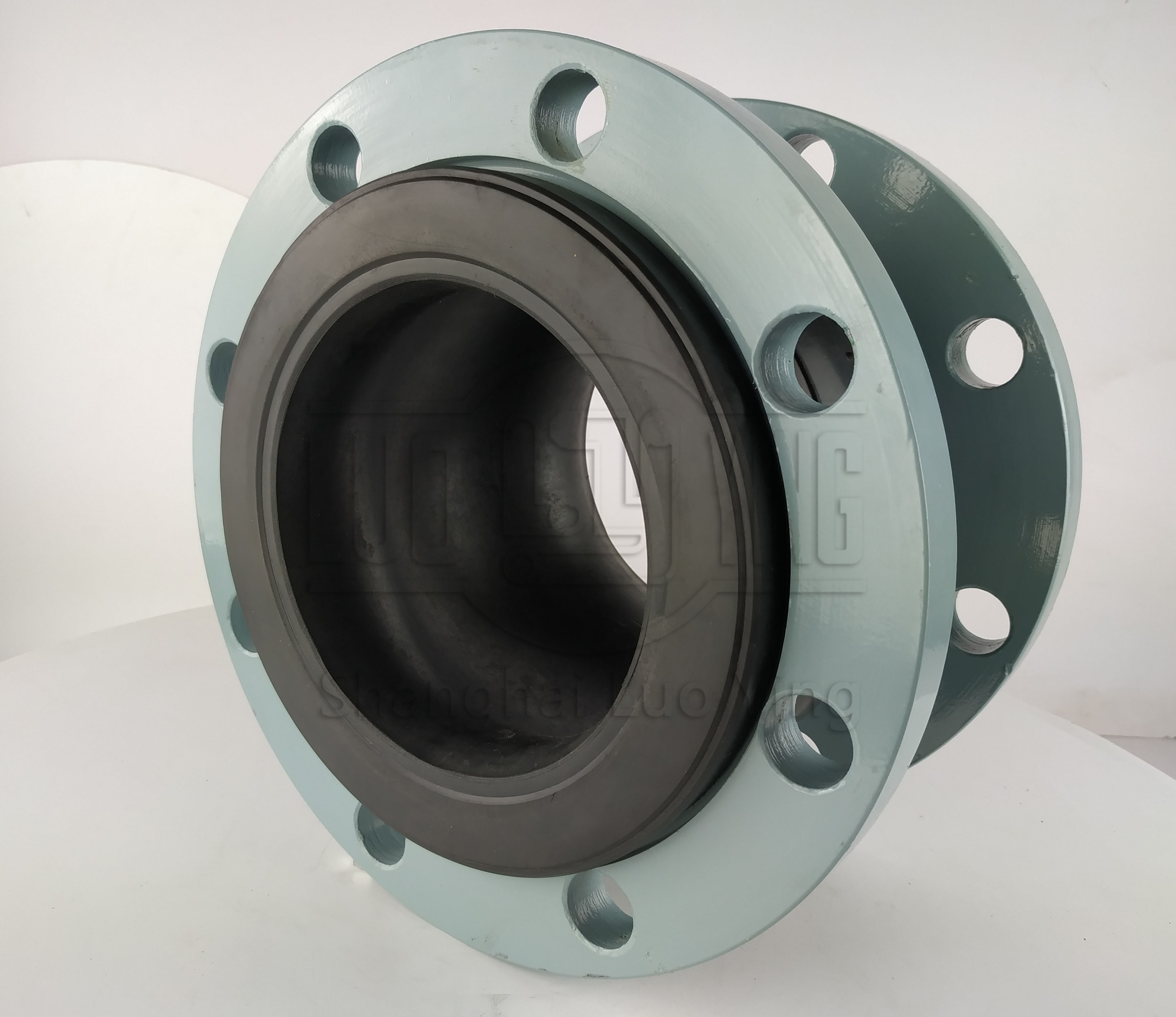

Luoying pipeline production of rubber expansion joint as a hose installed in the pipeline the only pressure-bearing body, both to accept the rigorous test of all aspects, but also as a protective device to protect the bellows, usually after understanding the specific pressure range of the site pipeline, to be made for this point, the choice of one or more layers of stainless steel wire for weaving. General rubber expansion joint working pressure is divided into 5 levels: 0.25, 0.6, 1.0, 1.6, 2.5Mpa.1, rubber expansion joint damage analysis, rubber expansion joint after running for a period of time, internal wear and corrosion, the entire joint pressure resistance is reduced, the medium contact stainless steel wire, of which chlorine ions will produce serious corrosion of stainless steel, corrosion leads to weakening of the outer wrap layer, the pipeline pressure reaches a certain level, the leakage accident so happened.

2, the outside of the rubber expansion joint, after twisting, so that the metal winding stainless steel protruding burr. Not only in the process of personnel maintenance has a great hidden danger, but also in serious cases, the surface metal damage, the entire hose fracture.

Rubber flexible joints, as the only pressure-bearing body of the hose installed in the pipeline, both in all aspects of the strict test, but also as a protective device for the bellows, usually after understanding the specific pressure range in the field pipeline, it is necessary to make for this point, the choice of one or more layers of stainless steel wire braid.