Installation and use of acid and alkali resistant rubber joints

Sep-22-27

According to the accident pressure of the pipeline, adjacent to the main, medium and compensation amount to choose the appropriate model, the number of noise reduction displacement requirements to choose.When the pressure of the pipeline is greater than the accident pressure, the joint should be higher than the accident pressure by one grade.

When the pipeline medium is acid and alkali, oil, high temperature meter and other special materials, the joint should be used one gear higher than the pipeline pressure.

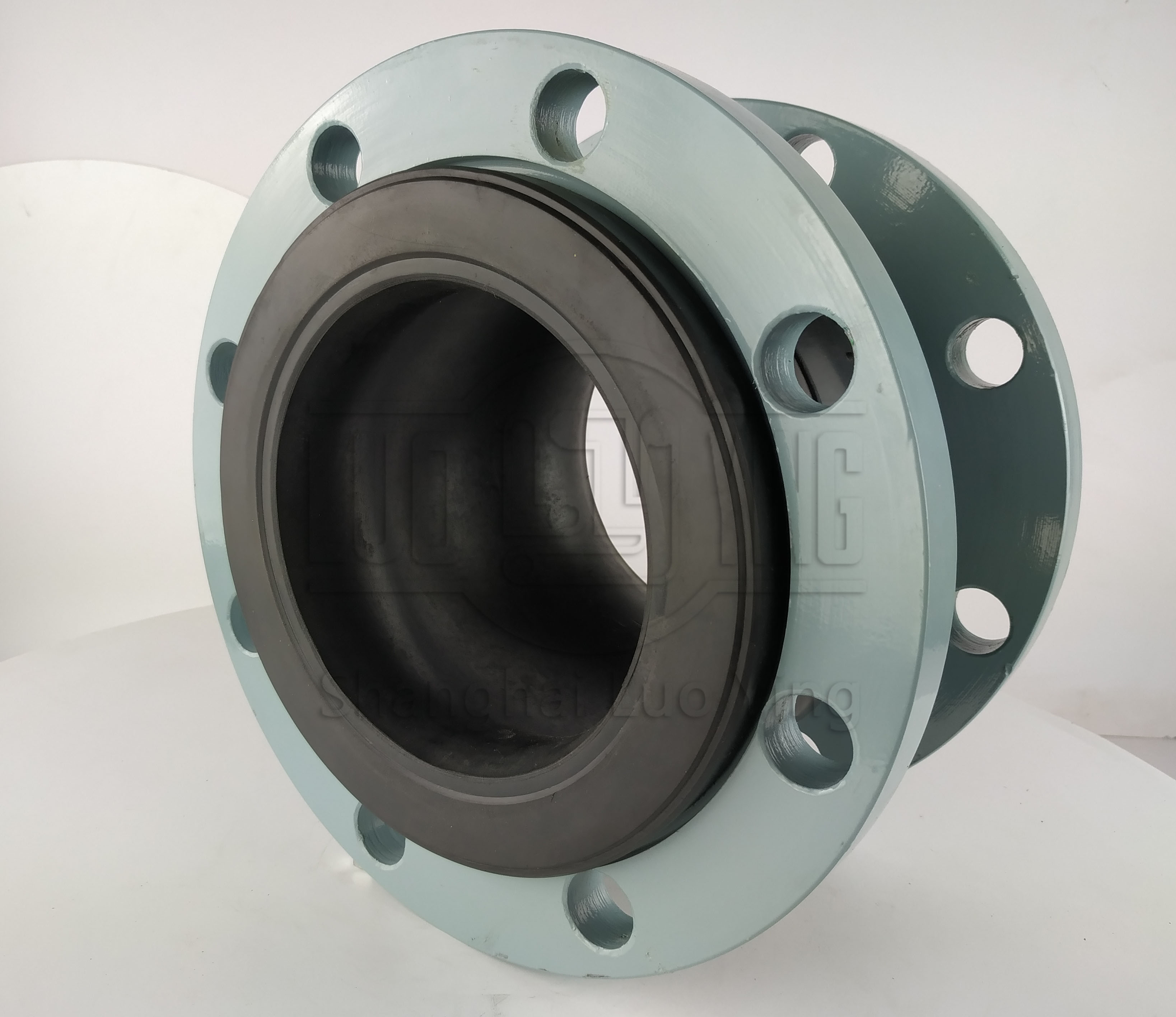

The flange of the rubber joint should be a valve flange or a suitable flange.

The normal practical medium of bendable rubber joints is the usual water at a temperature of 0-60°C. Special media such as oil, acid and alkali, high temperature and other corrosive and solid textures should be selected with the corresponding special resistant material rubber joints, not to be used blindly in series or in general.

Bendable rubber joints should be located near the pump side when they are used in the pump inlet and outlet, and metal reducer joints should be installed between them and the pump, and they should be installed in the large diameter of the reducer.

When the pipeline displacement is greater than or equal to the large compensation amount of the joint, the number of joints should be increased to parallel displacement, it is strictly forbidden to make the joint in the state of disturbance displacement and fault in order to mediate the super difference of the pipeline, not to mention the super limit expansion, displacement, deflection, etc.

High-level water supply goods suspended water supply, the pipe should be firmly on the hanger, bracket or anchor frame, and the joint should not be subjected to the pipe's own weight and axial force.

When installing the rubber joint, the screw of the bolt should be extended to the outside of the joint, and the bolt of each flange end face should be repeatedly tightened evenly according to the diagonal pressure to prevent pressure deviation.

The rubber joint should be re-pressurized and tightened before it is put into operation for the first time under pressure, or after a long period of disuse.

The use or storage of rubber joints should be restrained from high temperature, ozone, oil, acid and alkaline conditions. Pipes used outdoors or facing the sun and wind should be built with sun shelves, and exposure to the sun, rain and wind are strictly prohibited. The outer surface of the joint is strictly prohibited to paint and winding insulation materials. Because of the aging title of rubber products, should be real-time inspection and change.