Compensator flexibility and fatigue resistance properties.

Oct-22-06

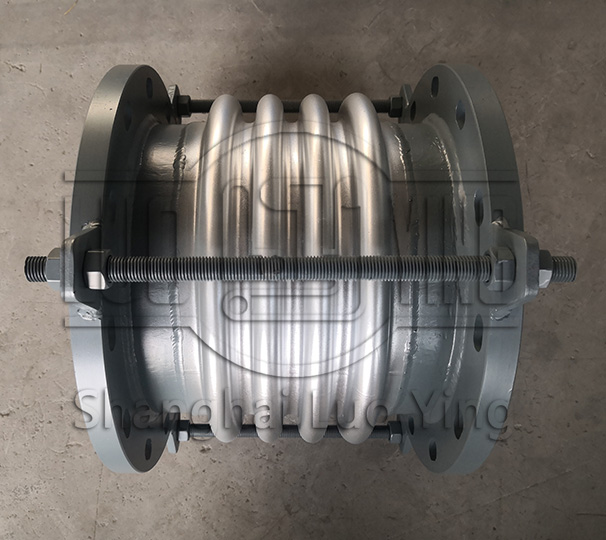

The use of the compensator determines that it is built with a certain strength, greater flexibility and high fatigue resistance, so the design of the bellows can only use thin-walled, multi-layer structure. Compensator manufacturers, operating under the conditions of the bellows is a typical low cycle of high stress components, its crest, valley of the local has entered the plastic, due to the bellows for a thin-walled flexible components, working under high stress, is the weaker part of the pipe system, and thus the reliability of non-metallic compensators become a concern. Non-metallic compensator in operation during the failure is mainly manifested as instability deformation and corrosion leakage in two forms, of which the corrosion failure is the majority. Compensator corrosion generally point corrosion perforation and stress corrosion cracking two types, which stress corrosion is a necessary condition for the existence of a corrosive environment and internal stress. The existence of stress is one of the necessary conditions leading to stress corrosion cracking, the sources of stress are: bellows processing and forming process generated during the deformation stress and residual stress; in the service period asked the working stress; improper assembly leads to excessive assembly stress, corrosion products caused by wedging stress.

Compensator manufacturers manufacturing range: round corrugated expansion joint DN50 ~ DN1200, rectangular corrugated expansion joint, axial, lateral, angular, universal, pressure balance type, vibration damping, seismic, direct burial and no thrust expansion joint, fabric expansion joint, metal hose, compensator, pipe support hanger, dampers.