How to avoid the rubber expansion joint being pulled off?

Oct-22-07

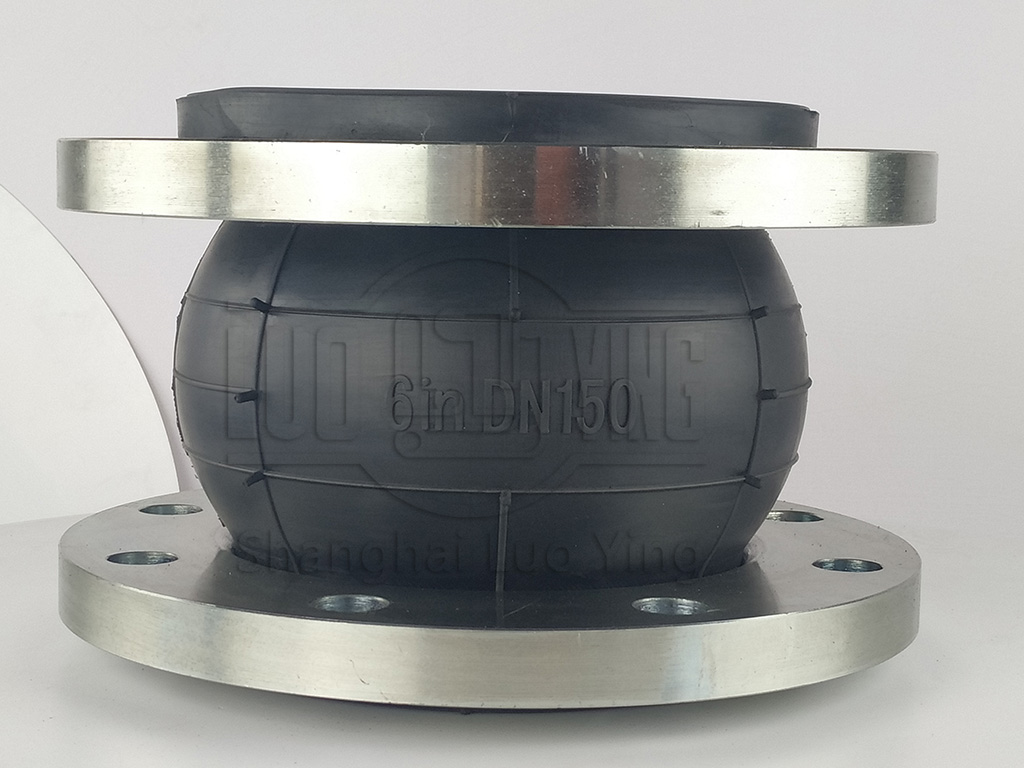

The main factors of the flange being pulled off are the following two points.1. The paired flange of the rubber expansion joint is not standardized, according to the national standard specification, a special flange for butterfly valve should be used, that is, a small diameter flange, to increase the contact area between the rubber sealing surface and the sealing surface of the paired flange, to prevent the phenomenon of pulling off.

2. In the pipeline installation is not fixed in place, resulting in the rubber expansion joint in the operation of the super limit displacement. If the lateral tension of the pipeline is relatively large, it is necessary to add an anti-pull-off device on the rubber flexible joint, so that the force of the rubber joint can be effectively protected to avoid damage to the rubber expansion joint due to the tension exceeding the rated limit.

The following points should be noted during installation.

The rubber joint paired flange must be a special flange for butterfly valve.

Rubber joints are strictly prohibited to be installed beyond the displacement limit during installation.

The installation should be far from the heat source, and the use of media that do not meet the requirements of this product is strictly prohibited.

The installation bolts should be tightened symmetrically and gradually to prevent local leakage.

Another method is to immediately carry out reinforcement on the rubber joint to create an anti-stretch rubber joint that is easy to apply. Simply speaking, the rubber expansion joint structure is reinforced, that is, the flange contains a screw limit switch, usually three or four bolts installed on the side of the rubber joint, adjusting the length of the bolt to adjust the expansion length of the rubber joint, so that in the case of pipeline offset, it has the ability to avoid the rubber expansion joint pull off the situation.