Installation and precautions for luoying compensator.

Oct-22-07

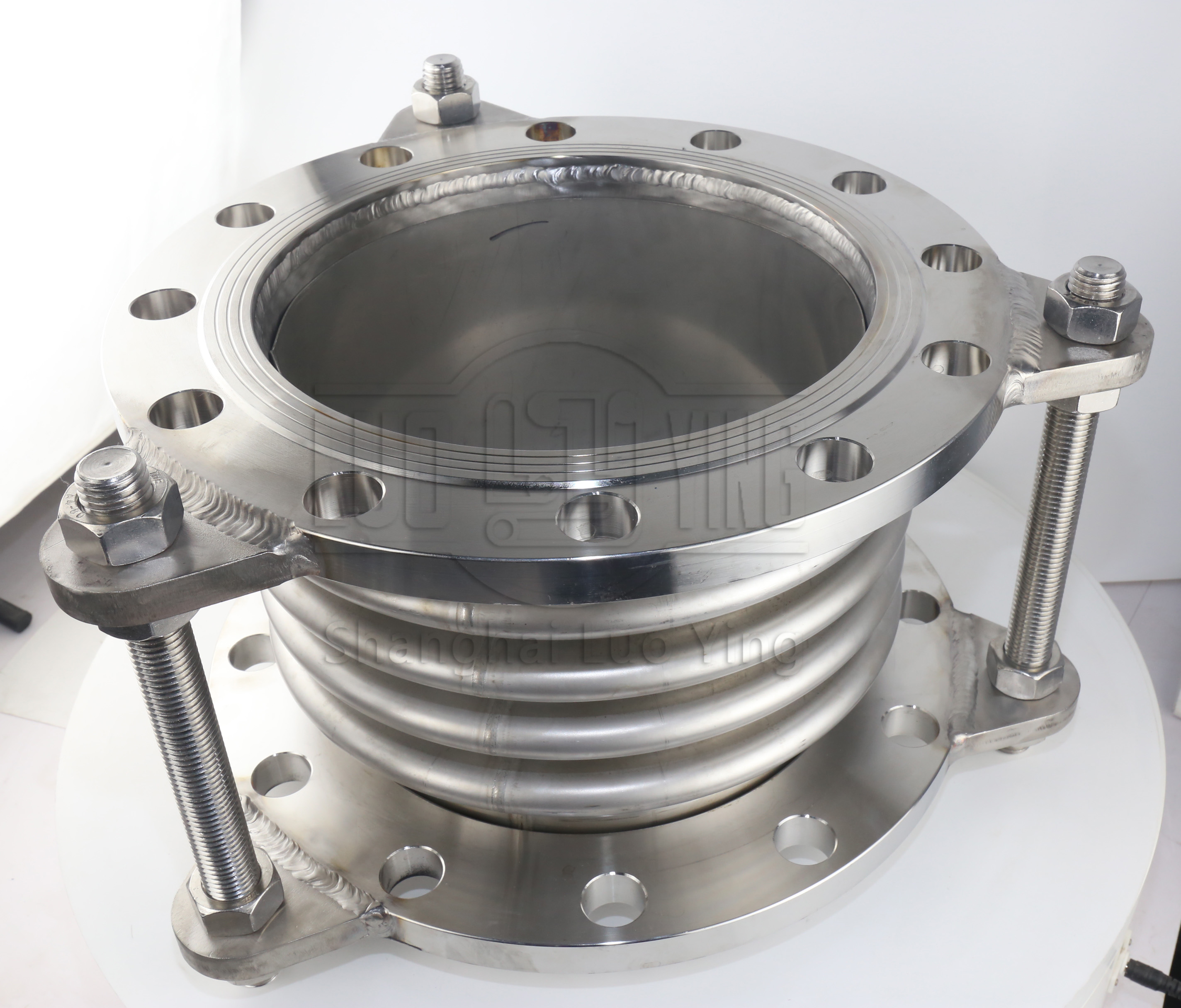

1. Check the product type, specification and pipeline configuration before installation to see if it meets the requirements.2. Compensator with inner sleeve should pay attention to the direction of the inner sleeve and the direction of media flow, hinge type compensator hinge rotation plane should be consistent with the displacement rotation plane.

3. Need to be "cold tight" compensator, pre-deformation of the auxiliary components used in the pipeline installation should be completed before removal.

4. Installation should be strictly checked for stones, iron sand and other debris in the corrugated compensator shell and pipeline.

5. It is strictly forbidden to use the method of deformation of the corrugated compensator to adjust the installation of the pipeline overrun, so as not to affect the normal function of the compensator, reduce the service life and increase the load of the pipe system, equipment and supporting components.

6. After the installation of the pipe system, the corrugated compensator should be removed as soon as possible for the installation and transportation of color auxiliary positioning components and fasteners, and according to the design requirements of the limit device to the specified position, so that the pipe system in the environmental conditions have full compensation capacity

7 . For gas medium compensator and its connecting pipeline, for water pressure test, to consider whether the need to fill the receiver of the compensator with a temporary bracket to bear the weight. Water pressure test water must be pure, non-corrosive, and control the content of chloride ions in the water does not exceed 25 ppm. water pressure test is over, the corrugated pipe should be drained of water as soon as possible, and quickly blow the inner surface of the wave shell dry.