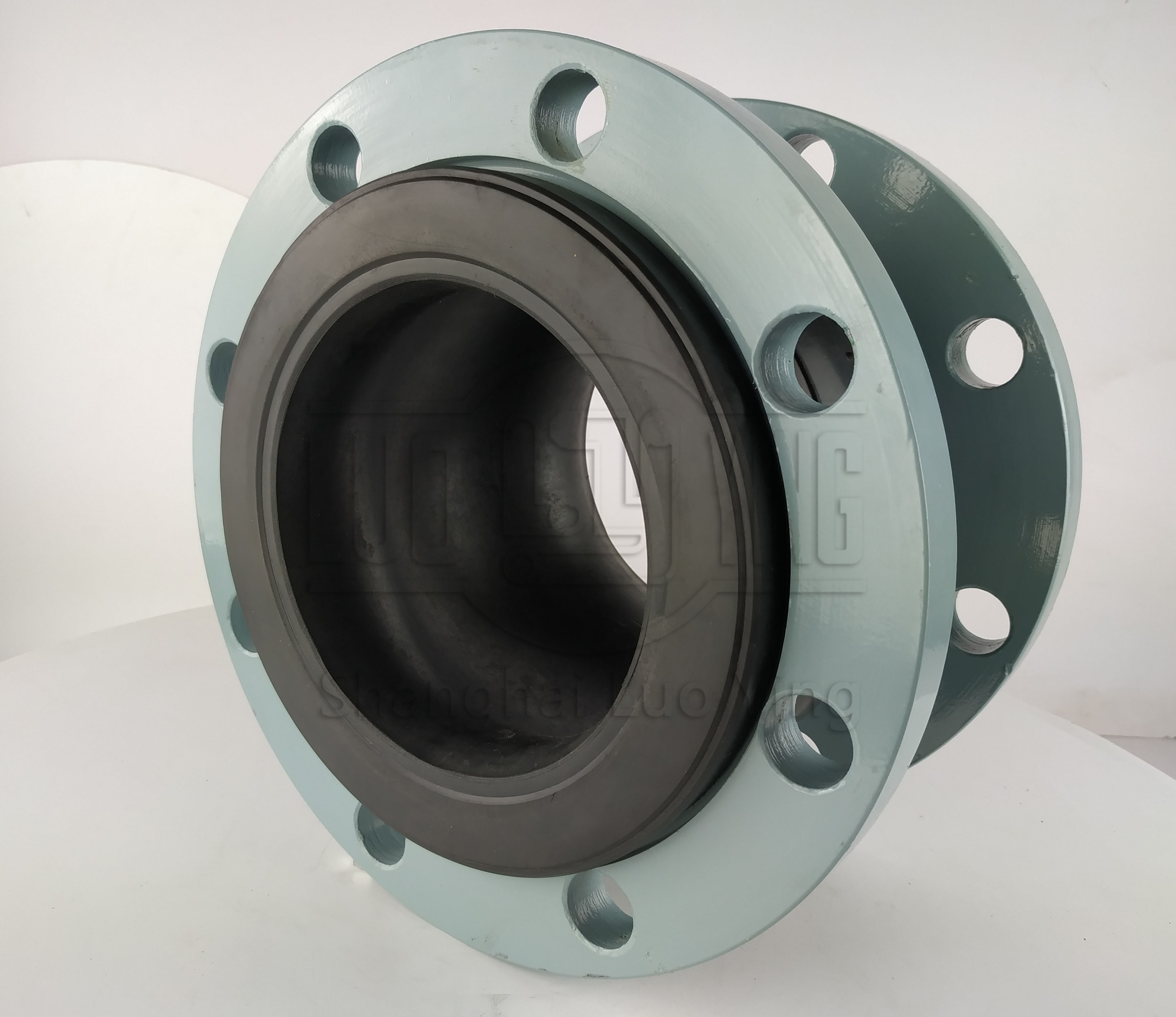

Installation precautions for high temperature resistant rubber expansion joints

Oct-22-10

1 . First must be allowed to be in a natural state, do not artificially make the product artificially deformed at the time of installation.2 . High temperature rubber expansion joint in high temperature pipeline installation precautions in the installation of flange connections, bolts require symmetry. When working in the pipeline should prevent the installation of super limit displacement .

3 . If the tightness check before installation of the rubber expansion joint is not in place, the defects of the rubber expansion joint is difficult to find and deal with, because the rubber expansion joint has a factory certificate, but in the process of transportation, loading and unloading, storage, etc., may be damaged by collision, smashing, etc., resulting in cracks or critical parts of the rubber expansion joint defects, damage, which can cause leakage of the valve, affecting normal use or rework maintenance, resulting in cost and material consumption.

4 . Vertical installation of the expansion joint pipe ends should be vertically supported by the force, can take anti-pull off device to prevent the work under pressure pull off.

5 . High-temperature rubber expansion joint installation site should be far from heat sources, ozone areas, strong radiation light exposure and the use of media that do not meet the requirements of the product is strictly prohibited.

6 . Rubber expansion joint in the transport handling is strictly prohibited sharp instruments scratch the surface, sealing surface.