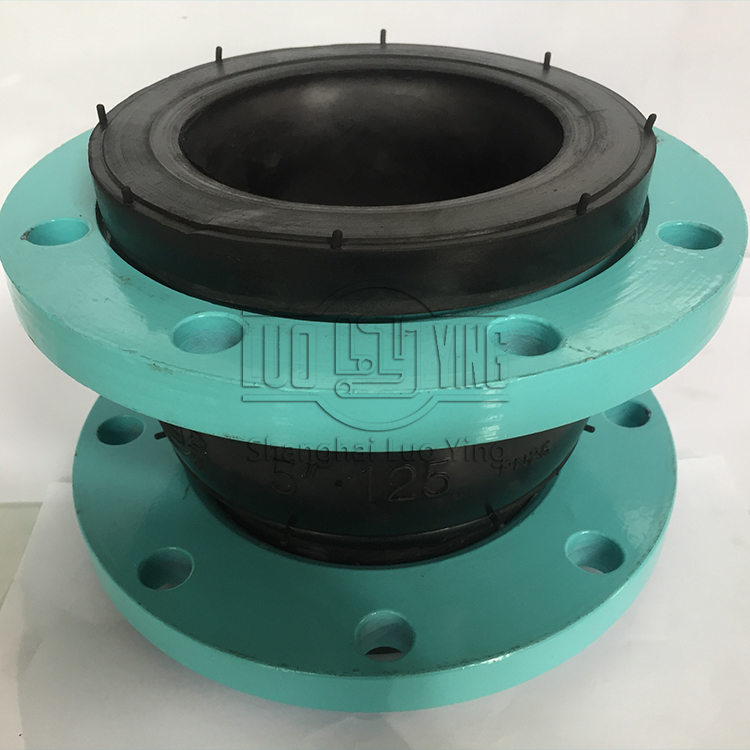

Rubber expansion joints of different materials and circulating media.

Oct-22-21

High pressure resistant rubber joint: Natural rubber NR (over water, below 80 degrees), high elasticity, high fixed tensile strength, excellent tear resistance and electrical insulation, good wear resistance and drought resistance.High temperature resistant rubber joints, acid and alkali resistant rubber: EPDM, characterized by excellent ozone resistance, ultraviolet resistance, weather resistance and aging resistance, excellent electrical insulation, chemical resistance, good impact elasticity, acid and alkali resistance, small specific gravity, high filling fit. Heat resistance up to 150℃.

Oil-resistant rubber: nitrile rubber NBR (oil-resistant, including hydraulic oil and other oils, long-term use temperature of 120 ℃) excellent oil resistance, high wear resistance, heat resistance is good, strong adhesion. The disadvantages are poor low temperature resistance, poor ozone resistance, poor insulation performance, and slightly lower elasticity.

Fluorine rubber (FPM): mainly refers to the synthetic polymer elastomer containing fluorine atoms on the carbon atoms of the main chain or side chain. At present, all elastomers in the good performance of media resistance. It is mainly used in the defense industry to make vacuum-resistant, high-temperature-resistant and chemically-resistant sealing materials or other parts on aircraft and rockets.

Because of the good comprehensive performance of rubber joints, it is widely used in chemical industry, construction, water supply, drainage, petroleum, light and heavy industry, refrigeration, sanitation, plumbing, fire-fighting, electric power and other basic projects. Instructions for use: When using rubber joints for high-rise water supply, the pipeline must have fixed support or fixed bracket, otherwise the product should be installed with anti-pull-off device.