The installation of rubber joints in the chemical industry should pay attention to the characteristi

Oct-22-24

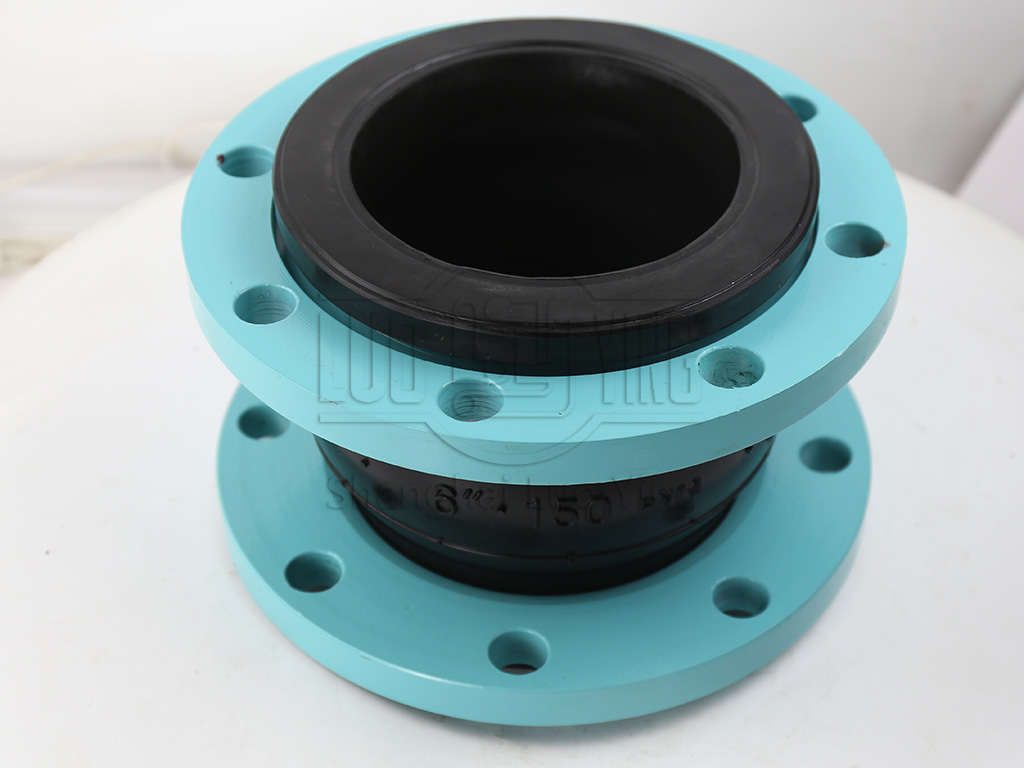

Chemical industry is a very important part of the national economy, which plays a very important role in promoting the development of the whole national economy. With the continuous advancement of industrialization, all industries in society are moving forward, and the chemical industry has been moving more and more in the direction of high precision in recent years, and in the overall development and reform of the industry, it is very important to choose other pipeline fittings to match. This product can be adjusted for different pipeline environments by adjusting the product's rubber material so that the rubber joint has a better adaptability.As we all know, the chemical industry pipeline network is common in the pipeline interior generally has different degrees of acid and alkali corrosion, in this case, the user in the process of purchasing rubber joints for the pipeline environment to choose the strength of acid and alkali rubber joints, this is because there are many types of acid and alkali resistant rubber joints, their respective acid and alkali resistance performance has a certain difference.

EPDM rubber joints have the ability to adapt to weak acid and alkaline pipeline environments, and can play a good role in the less acidic and alkaline pipeline environment, and have a certain degree of high temperature resistance to ensure normal operation of the pipeline within 120 degrees Celsius, thus improving the stability of the pipeline operation. There is another kind of rubber called neoprene, which is generally installed on the pipeline of the sea drainage project, mainly for the corrosive environment of seawater to ensure the normal operation of the pipeline.

The latter is fluoroelastomer joint, which is a kind of rubber joint with high cost performance in the field of acid and alkali resistance, and can meet most of the acid and alkali pipeline installation environment nowadays, the rubber material has good acid and alkali resistance, where acid and alkali refers to strong acid and strong alkali, even in some corrosive pipeline installation environment this rubber joint can also play a good adaptability, in addition, the product In addition, the high temperature resistance of the product is also very good, the pipeline temperature below 180 ℃ can be well adapted, the product can meet most of the acid and alkaline pipeline operating environment at this stage.