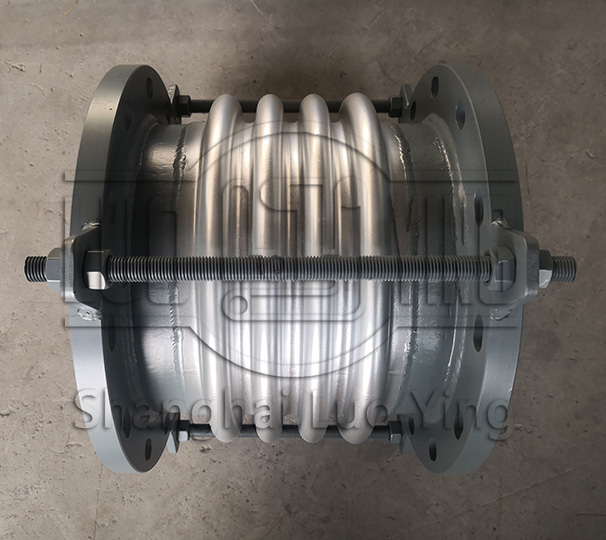

Control of various links of corrugated expansion joints for heating pipes

Oct-22-29

Centralized heating pipeline corrugated expansion joint application should be strengthened before installation, installation and acceptance and other aspects of control: before installation, the appearance of the expansion joint needs to be carefully checked, and proofread the product quality certificate, carefully read the installation instructions.During installation, drilling, heating and pounding on the pressurized outer cylinder are strictly prohibited, and deformation of the pressurized outer cylinder should be avoided as much as possible to avoid jamming of the inner guide. In order to ensure that the pipe system at the installation of expansion joints coaxiality deviation is at a small, before the installation of expansion joints, first lay the pipe section, and then in preparation for the installation of expansion joints, the pipe will be cut off (its length should be equal to the length of the expansion joint out of the field), and then the expansion joint will be installed and welded.

During the lifting process of the expansion joint, the spreader is strictly forbidden to be set on the pressure-bearing outer cylinder and should be lifted at the preset lifting place. It is strictly forbidden to adjust the deviation of the pipeline by deformation of the expansion joint. When testing pressure, the pipe system equipped with expansion joints shall not be tested for system pressure until the fixed bracket, guiding bracket, sliding bracket, etc. are installed according to the requirements of the construction drawings. If it is a direct buried pipe, the system test pressure shall not be carried out before the pipe system is backfilled as required by the drawings.

Before the test pressure is carried out in sections, it should be ensured that the fixed brackets at both ends of the pipe section have sufficient strength to ensure the operation of the pipe section and the expansion joint. The test pressure of the pipe system should be clean water, the chloride ion content of the water should not exceed 25 PPm. The environment and air media around the storage and application of the expansion joint should not contain harmful media that can cause corrosion of the expansion joint.