Reasons for blistering of rubber flexible joints

Nov-22-04

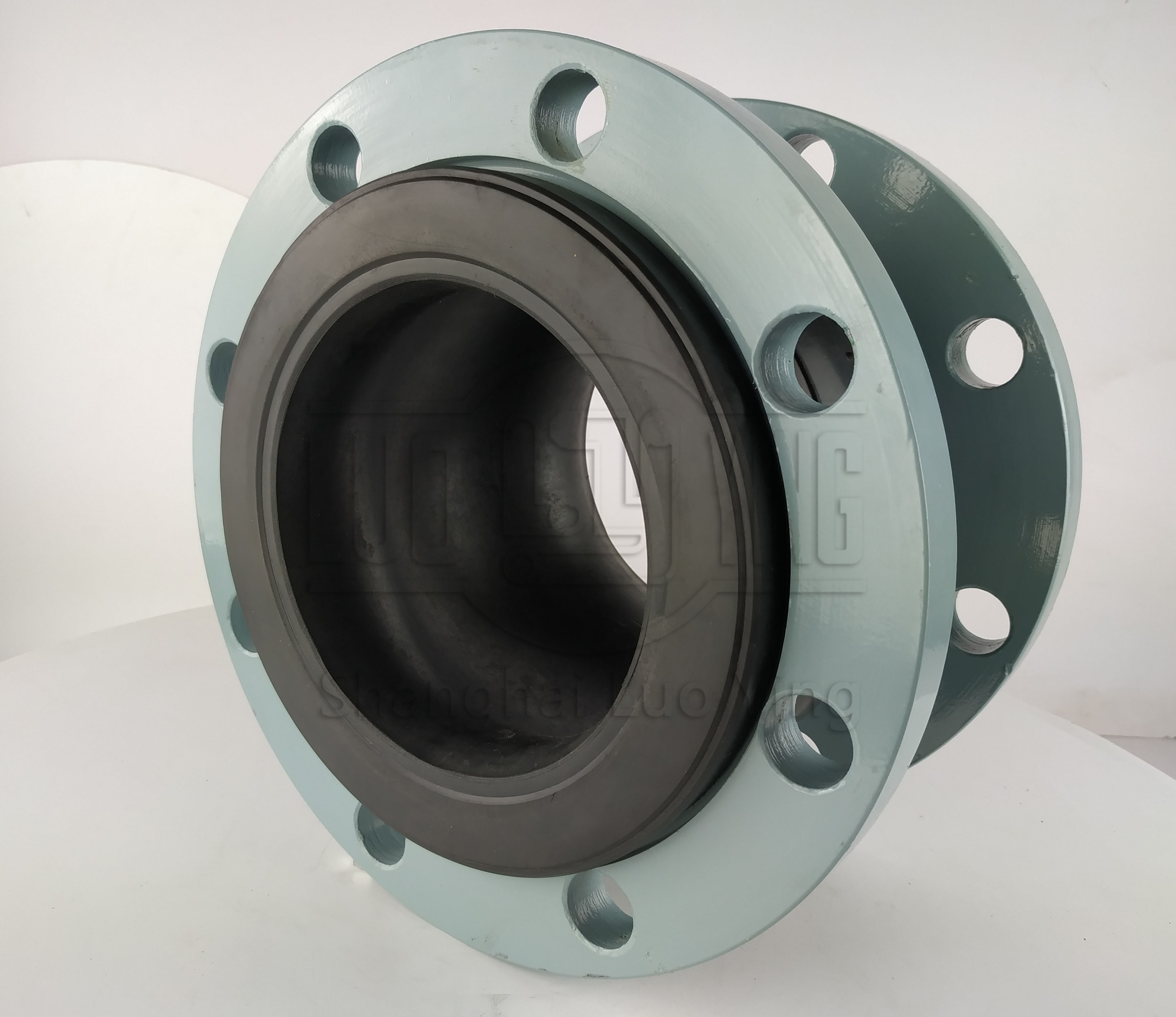

The main reason for blistering of rubber soft joints is caused by some improper operation during processing, the bonding of inner rubber cord and rubber is not close enough, resulting in gaps in the inner rubber layer. After installation, water enters the inner layer through the gap, resulting in blistering and leakage of the rubber joint. There may be a problem of raw materials and a problem of time pressure.The material of the rubber expansion joint is rubber, blistering is also a common phenomenon, and the problem is found as long as it is avoided in time. Blistered rubber joints are bad products, so they can not continue to use, even after installation is not safe to use, first of all, the length of time, followed by the use of security issues, so do not continue to use the rubber joints encountered blistering, and must promptly contact the manufacturer, for safety reasons, blistered rubber joints in the project is strictly prohibited.

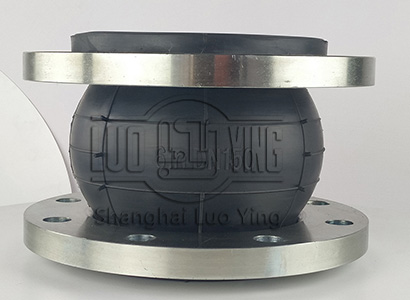

Rubber mixing is not uniform, the operator is not standardized.

The environment is not sanitary, the management is not standardized and other reasons cause too much mixing of other impurities in the rubber.

Vulcanization is not sufficient, not ripe looks bubble.

Long plasticizing time of rubber. More impurities of vulcanizing agent, small molecules of impurities become decomposition in advance, bubbles remain in the products

The product is too thick, the rubber material is too little, and the rubber is slow in heat transfer. After vulcanization, the fluidity of rubber is reduced, resulting in material shortage and possible bubbles. The exhaust of the vulcanization process is not completely discharged.