Rubber expansion joint installation is not standardized? The consequences are serious

Nov-22-10

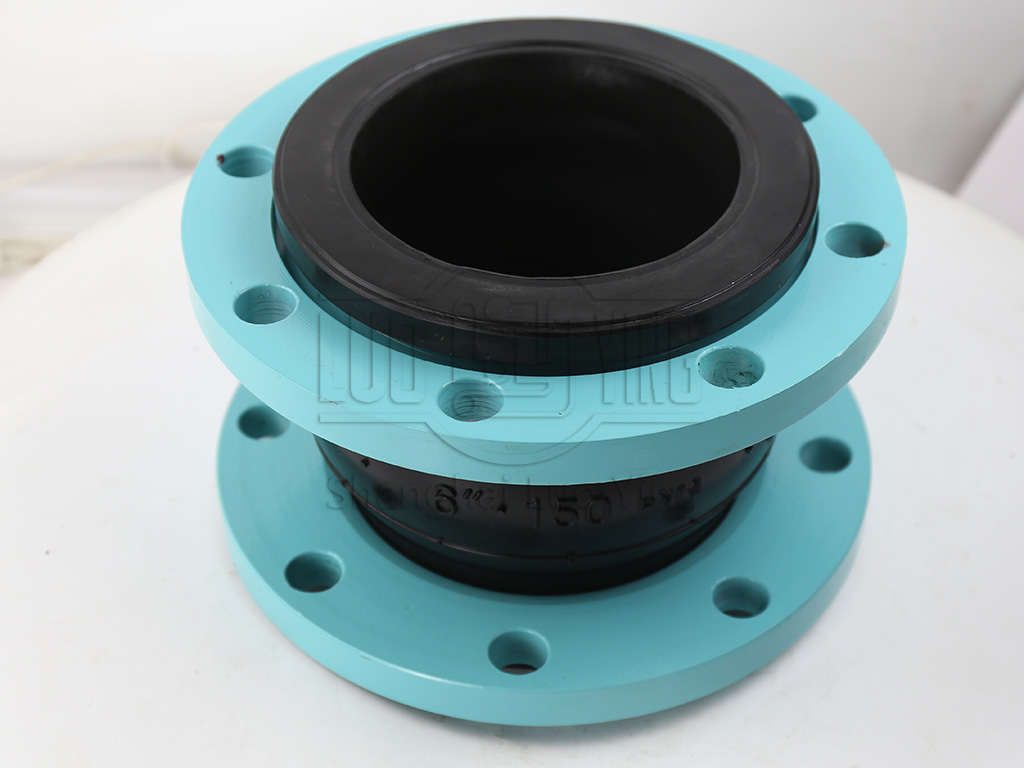

Rubber soft joints are mostly installed inside the pipeline, in addition to a small repair of the tilt degree of the pipeline, but also plays a role in shock absorption and noise reduction of the pipeline, which is a very practical pipeline connection.When often because of irregular installation and operation, resulting in pipeline problems, the reason is the problem of rubber joints, summarized due to the installation of rubber joints will not be standardized in several cases, as follows.

1 . Leakage of rubber joints: most of the leakage occurs from the installation of irregularities caused by the installation, tight screws is a process that is important, the diagonal twisting method must not be changed, otherwise there will be a local seal is not tight, which leads to the occurrence of rubber joint leakage.

2 . Rubber soft joint pulling: this situation is because the actual stretching of the installation pipeline exceeds the stretching length of the rubber joint, which leads to the flange from the two ends of the sphere is forced out, in this case, please promptly replace the double sphere rubber soft joint to use, or can also be used in the rubber soft joint with a limit device, limit device in addition to the stretching of the rubber soft joint has a certain specification In addition to the stretching of the rubber flexible joint, the vibration of the pipe also has a really big improvement.

3 . Soak deformation of rubber flexible joints: this happens in the installation of ordinary rubber flexible joints in the oil pipeline, because the oil rubber has a corrosive effect, a long time soak will be swollen rubber flexible joints, resulting in sealing problems and their own quality problems decline, so the choice of oil-resistant rubber flexible joints in the oil pipeline.

4 .Size deformation of rubber flexible joints: the size deformation comes from the strong degree of distortion of the pipeline. Due to the large degree of inclination of some pipelines, which leads to their own distortion during transportation, the rubber soft joint is a particularly resistant product, but for the distortion is inevitable, this situation will replace the rubber soft joint with a high-pressure rubber soft joint.