Introduction of rubber joint material: choosing different rubber can play different roles

Nov-22-15

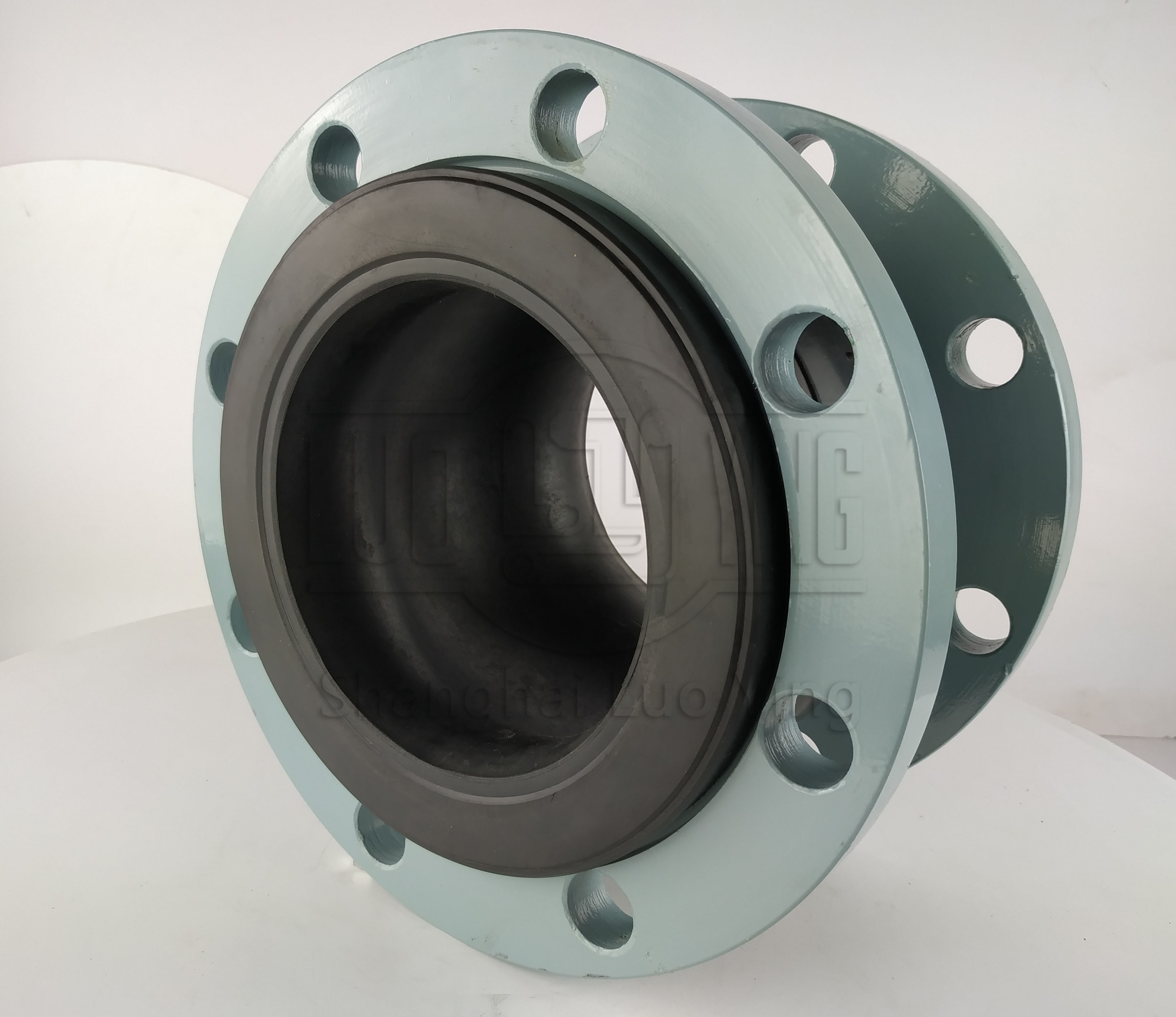

Rubber joint is a flexible connector for metal pipeline, which consists of rubber sphere with inner rubber layer, nylon curtain fabric reinforcement, outer rubber layer compound and loose metal flange. It has vibration damping, high temperature resistance, flexing and friction resistance, etc. Color, suitable for pipeline misalignment, displacement, scale changes and vibration parts of the connection, can be used for storage tanks, tankers and other equipment to give, discharge pipe, but also for other purposes. It is widely used for conveying air, compressed air, water, seawater, oil, acid, alkali, etc. from -15℃ to 120℃. The special type rubber joint is used for conveying the above medium or oil, concentrated acid and alkali, solid materials above -30℃~250℃ .Material introduction : choose different rubber can play different roles.

1、Inner rubber: NR, NBR, EPDM (can choose high temperature resistance, acid and alkali resistance, oil resistance, wear resistance, etc.)

2, outer layer rubber: NR, NBR, EPDM (can choose high temperature resistance, acid and alkali resistance, oil resistance, wear resistance, etc.)

3、Body skeleton: nylon cord fabric (the same material as inside the tire)

4、Booster ring: high pressure steel wire rope

5, flange: carbon steel Q23 (forging) surface spraying anti-rust baking paint, stainless steel 301, stainless steel 316L, PVC material

1, natural rubber NR (over water, below 80 degrees)

2, EPDM (high temperature 120 degrees or less, acid and alkali resistance, corrosion resistance, power plant desulfurization, lime slurry, gas, etc.)

3, nitrile rubber NBR (oil-resistant, including hydraulic oil, aviation kerosene and other oils, high-temperature resistance of 120 degrees or less)

4, wear-resistant rubber (wear-resistant, generally used in the mineral industry, granular media transport pipeline)

5, special rubber (emulsion, sulfuric acid and other special media)