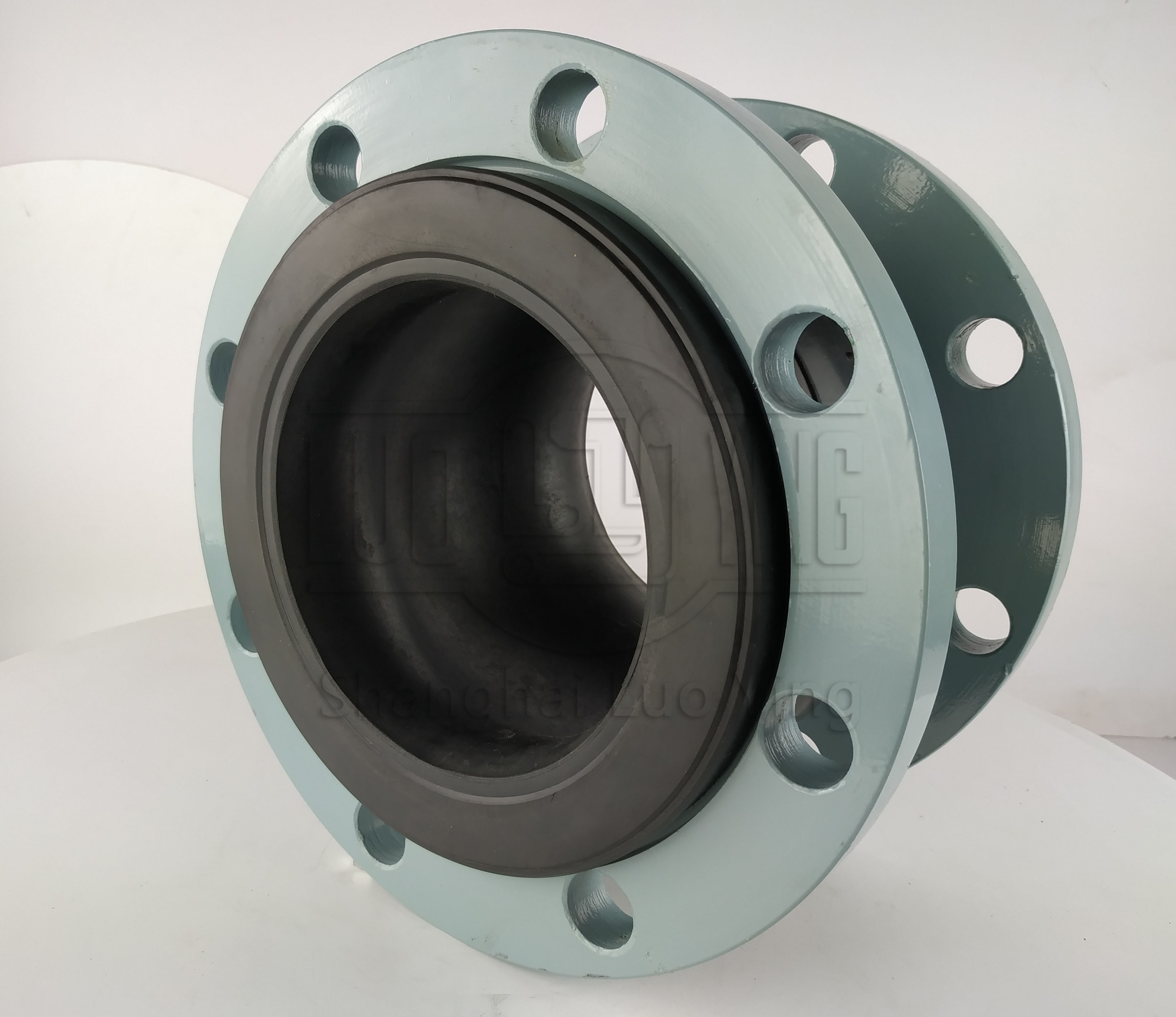

How to deal with the cracking of rubber expansion joint connection part?

Nov-22-16

The reasons for heavy skin and cracking of flexural rubber joints during production are as follows.1. The vulcanization speed is too fast, and the rubber flow is not sufficient.

2. dirty mold or rubber sticky stains.

3. too much isolating agent or mold release agent.

4. the thickness of the rubber is not enough.

When you use rubber joints, the following situation often occurs: the installation is good, and after a period of time, you suddenly find that the sphere flange link has a small crack with fine lines.

Rubber joints cracking in the process of use causes.

1. The strength of the rubber joint link part is low, then if the gluing method is not accurate, the strength of the joint will be even lower, there may be cracking.

2. The length of the rubber joint is not long enough in the process of using the link, forcing the length of the link beyond the link and arbitrarily expanding the shrinkage range may also crack.

3. After the rubber joint is installed, it may also crack if it is pulled in other places of the pipeline beyond the expansion range.

4. Rubber joints may crack under the influence of outdoor bad weather, such as bursting sun, which is lower than the use temperature.

5. Rubber joints in the production of vulcanization process used in the rubber rubber function is not good or has been since the sulfur failure, excessive grinding, rusting of steel wire rope, etc., the strength of the joint parts will be greatly reduced, in use, there may be easy to flood the joint parts disconnected phenomenon.