Metal Expansion Joints

Industrial applications are some of the harshest environments in industry, subject to intense heat, pressure, vibration, and their combined effect on plant equipment.

Metallic expansion joints are available in a wide range of materials: from various stainless steel, high nickel alloys (Inconel, Hastelloy, Monel), Duplex stainless steel, and Titanium.

An expansion joint is any apparatus containing one or more metal bellows used to absorb dimensional changes such as those caused by thermal expansion or contraction of a pipeline, duct, or vessel and to absorb vibrationscaused by engines, pumps, motors, etc.

In other words, a metal expansion joint is a device primarily formed by flexible bellows used to absorb movements in a piping system while containing pressure and a medium running through it.

The key element of an expansion joint is the bellows. The bellows is a flexible element consisting of one or more corrugations and the end tangents.A corrugation (convolution) is the flexible unit of a bellows and end tangents are the straight un-corrugated portions at the ends of a bellows.

The flexibility of the bellows is derived from the inherent flexibility of the corrugation given its shape and its own design.

Application:

Thermal expansion of piping.Flexible equipment connection when higher temperatures and compression movement is required.

Media:

Seawater, fresh water, drinking water, domestic sewage, crude oil, fuel oil, air, gas, steam and granular powder.

-

Materials

Materials304L, 310, 316, and 316L.

-

Size

SizePipe- 2-1/2” - 100”

-

Temp

Temp-420°F to +1800°F.

-

Pressure

Pressure50, 150, and 250 psi

Product Range

-

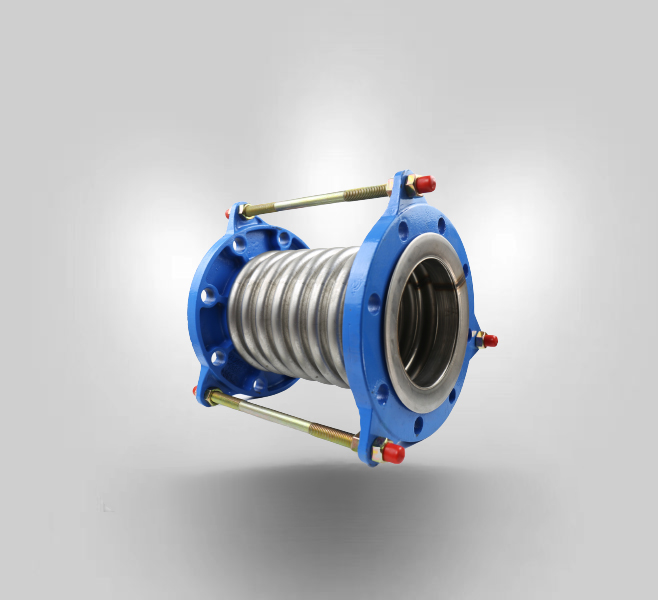

JXH Small Tod Horizontal Corrugated Compensator

Expansion joints come with three convolutions as a standard. More than three convolutions can be customized and the more convolutions, the more movement an expansion joint will provide. Various reinforcements of rings and outer shells are available for hi

View More

-

JDH Large Rod Bellows Compensator

Thermal movements would generate in any rigid pipe systems because of temperature changing. Due to its annular corrugations, the Style LD-MC Stainless Steel Flexible Connector allows for axial compression or axial extension, lateral deflection as well as

View More

-

FVB Rectangular Air Flue Non-metal Expansion Joint

Air flue rubber joint compensator is composed by rubber composite materials, steel flange, sleeve, thermal insulation materials. Mainly used in various fan, air duct for flexible connection. The function is shock absorption, noise reduction, sealing, medi

View More

-

JZM Buried corrugated compensator

Buried corrugated compensator mainly used in buried pipe axial compensation, has super anti-bending ability, so buried compensator shell can freely expansion compensation under the protection of sleeve.

View More

-

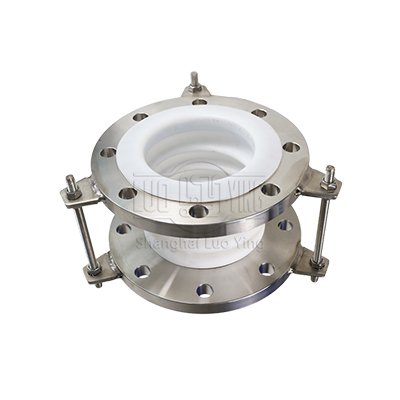

PTFE lined corrugated expansion joint

Metal bellows expansion joints (also called compensators) are compensating elements for thermal expansion and relative movement in pipelines, containers and machines. They consist of one or more metal bellows, connectors at both ends, and tie rods that de

View More

-

FGFB Rectangular Crrugated Compensator

Rectangle ripple compensator (FGFB) also called rectangle of corrugatedexpansion joint, and rectangular corrugated expansion joint, axial, lateral,angular compensation function. Especially suitable for power plants, steel mills, coke, cement industry, smo

View More

-

JWJ Universal Hinged Metal Compensator

Universal hinge compensator mainly compensate bending pipeline synthesis displacement by the way of angular deflection.

View More

-

Pressure balanced expansion joint

Pressure Balanced Expansion Joints do not transfer the internal pressure thrust on to the fix points, adjacent equipment, or structures. Fix points are usually not required, only guides can ensure the turning of thermal expansion into a controlled movemen

View More

-

Metal Bellows Expansion Joint Compensator

Metal bellows expansion joints (also called Metal Expansion Joint) are compensating elements for thermal expansion and relative movement in pipelines, containers and machines. They consist of one or more metal bellows, connectors at both ends, and tie rod

View More

-

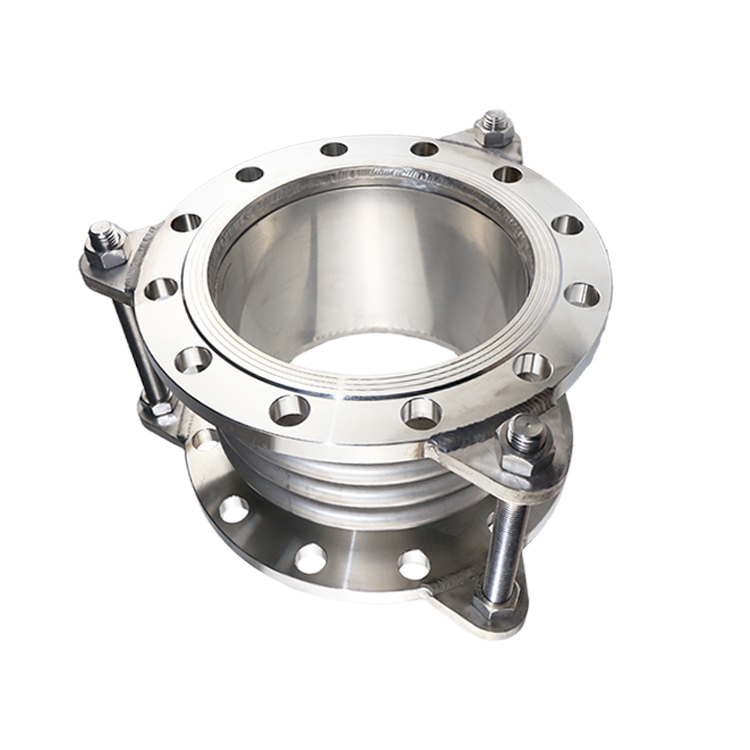

Sleeve Type Metal Expansion Joint

Sleeve type compensator is also called tubular expansion joints,Is the hot fluid pipeline compensator,mainly used for line pipe and auxiliary axial thermal expansion displacement after absorption compensation,is a kind of directly installed in any transpo

View More

-

JZW axial external pressure corrugated compensator

Axial external pressure bellow compensator also called shock absorption ripple compensator, corrugate pipe, expansion joint or slip joint.

View More

-

JJL Hinged Corrugated Expansion Joint

Hinge corrugated compensator also called expansion joint, slip joint, composed by bellows, tube, bracket, flange and catheter.

Design temperature:-20~+400℃View More

Customized Products

Technical Notes

Metal Expansion Joints main parts and accessories

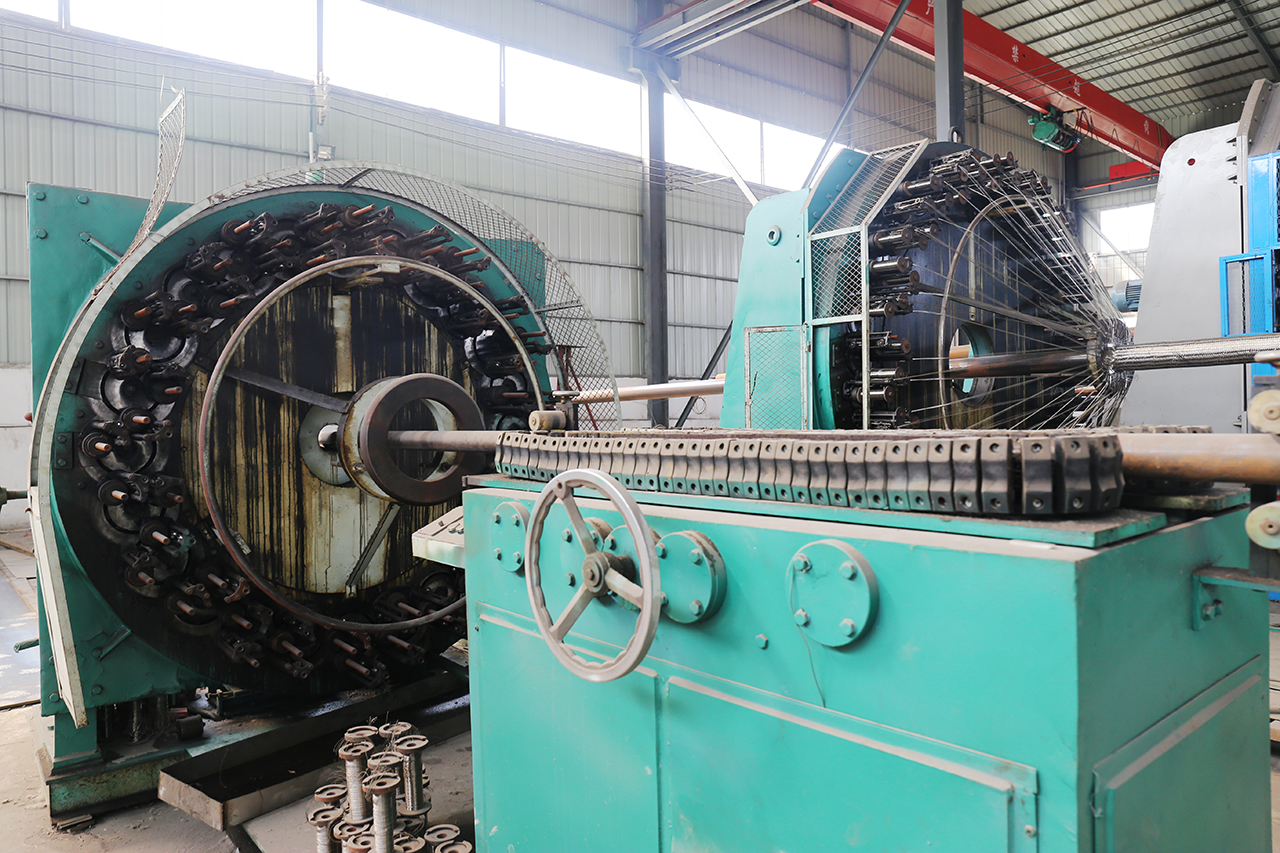

The multi-ply design

In modern expansion joints, the metal bellows are often produced with a so-called multi-ply design. To increase both flexibility and stability, multiple thin plies of metal are layered to form the bellows walls. There are two basic design types: The multi-ply and the multi-walled bellows structure. The multi-ply structure consists of a pressure-tight, longitudinally welded outer and inner cylinder of stainless steel. In between these cylinders is an open, spiral cylinder which forms multiple plies depending on the design. The multi-walled structure consists of several concentric, longitudinally welded cylinders. Each cylinder forms a pressure-tight and closed "wall".

Compensation types

In axial compensation, the thermal expansion of a straight line section between two fixed points is absorbed by an axial expansion joint. The distance between two fixed points defines the pipeline length requiring compensation, and thus determines the axial movement that must be achieved by the expansion joint.

The angular compensation of thermal expansion requires at least two, and for full compensation even three, angular expansion joints. Angular expansion joints offer a wide variety of combination options in so-called two-hinge or three-hinge systems.

Lateral compensation is likewise associated with a redirection of flow by 90° within single-plane or multi-plane piping systems. Usually, lateral expansion joints are installed in existing right-angle redirections in the system. The movement of a lateral expansion joint always consists of the desired lateral movement and a slight unavoidable axial movement that comes from the expansion joint itself.

Metal Expansion Joints main parts and accessories

Bellows

A flexible element consisting of one or more corrugations and the end tangents.The bellows can be singleply or multiply.

Connections

The most common types of connection parts are weld ends or flanges. In some cases male or female threaded ends are used.

Weld ends

The ends of an expansion joint equipped with pipe for weld attachment to adjacent equipment or piping. Weld ends are commonly supplied beveled for butt welding.

Flanged ends

The ends of an expansion joint equipped with flanges for the purpose of bolting the expansion joint to the matting flange of adjacent equipment or piping.Flanged ends can be supplied fixed or swivel.

Advantage

Nsure that the hose meets the published levels.-

pressures

They maintain a high degree of flexibility even when working under high pressures. -

leakage

Possibility of leak detection holes for early indication of leakage. -

media

Possibility of installing leak detectors for critical media. -

movements

Few units are required within any given system owing to their greater capacity to absorb movements. -

structures

The low spring rates reduce the costs incurred by anchorage and supporting structures. -

spring

They have lower spring rates than the single thick sheet bellows.

Expansion joint accessories

Quality decides value-

Flange

Piping components can be bolted together between flanges. Flanges are used to connect pipes with each other, to valves, to fittings, and to specialty items such as strainers and pressure vessels. A cover plate can be connected to create a "blind flange" Flanges are joined by bolting, and sealing is often completed with the use of gaskets or other methods. Mechanical means to mitigate effects of leaks, like spray guards or specific spray flanges, may be included. Industries where flammable, volatile, toxic or corrosive substances are being processed have greater need of special protection at flanged connections. Flange guards can provide that added level of protection to ensure safety.

-

Covers

Fasteners are used for fastening and securing materials such as wood, metal, plastic, or concrete. They include nuts and bolts, threaded rods, structural bolts, machine screws, wedge anchors, washers, rivets, and more in a variety of types and sizes, including metric and inch.

-

Particulate barriers/purge connectors

In systems that have a media with significant particulate content (i.e. flash or catalyst), a barrier of ceramic fiber can be utilized to prevent corrosion and restricted bellows flexibility resulting from the accumulation of the particulate. Purge connectors may also be utilized to perform this same function. Internal liners must also be included in the design if the expansion joint includes purge connectors or particulate barriers.

-

Liners

A gasket is a mechanical seal which fills the space between two or more mating surfaces, generally to prevent leakage from or into the joined objects while under compression. It is a deformable material that is used to create a static seal and maintain that seal under various operating conditions in a mechanical assembly.