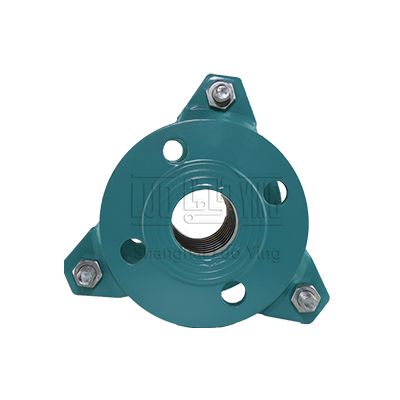

Metal Bellows Expansion Joint Compensator

- [Name]: Metal Bellows Expansion Joint Compensator

- [PN]: 0.6-2.5Mpa

- [Medium]: Air, water, seawater, oil, slurry, weak acid, alkali, etc.

- [Material]: SS304, 316, Q235 etc.

- [Certification]: ISO9001:2008

- [Products]: Metal Bellow Compensator, Metal Bellows Joint, Metal Expansion Joint

Overview

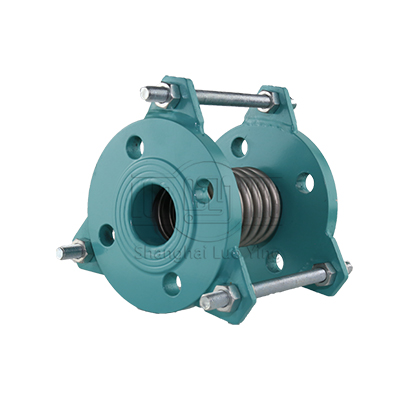

The Bellows Connector metal expansion joint is kept stocked with 150# C/S flanges and tie rods. Although it only comes in one configuration, it is an economical choice, and appropriate for many applications.

It uses vanstone 150# flanges, keeping all the wetted parts stainless steel, and has tie rods standard.

Pipe guides are also available for use with all metal expansion joints.

Detailed product description:

1.Nonmetal expansion joint.

2.Absorbs thermal expansion and shock.

3.Compensates converting misalignment.

4.Metal expansion joints are used in a wide variety of piping application to compensate for thermal expansion or contraction and to absorb equipment vibration or pipe motions.

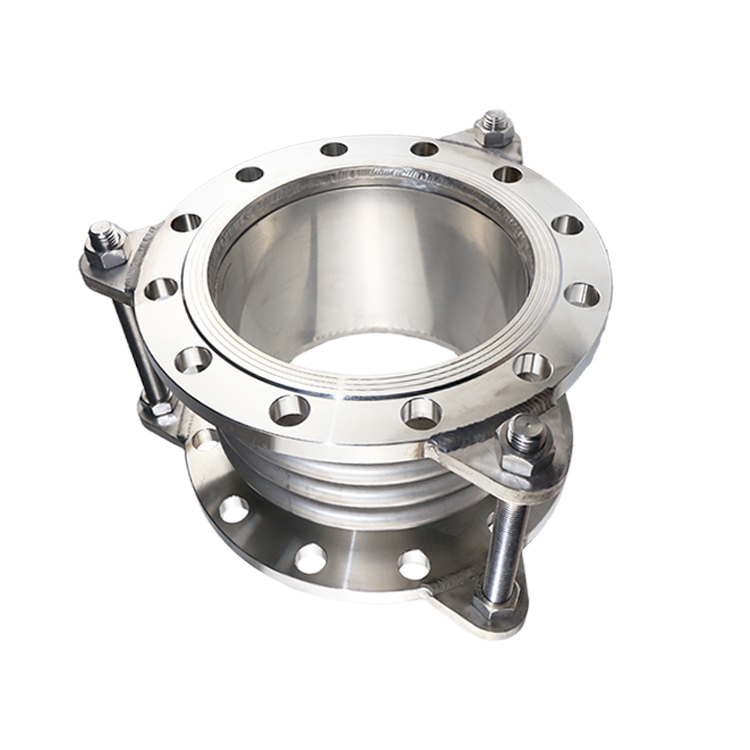

5.We manufacture single, two-ply and multiply testable bellows in different sizes using precision forming technology.

6.The bellow is made of stainless steel, whcih have good performance for extreme pressure, temperature and corrosive conditions.

7.Compensate axial movements.

8.Optimized design for fatigue resistnce and endurance.

9.Widely used to absorb termal expansion in pipe systems carring water, steam, oil and gases.

10.Stainless bellows compensators or expansion joints are designed according to the client's specifications ad design conditions.

Features

FEATURES:

Kept in stock

Economical

Comes standard with tie rods and 150# CS vanstoned flanges that allow all stainless steel wetted parts

APPLICATIONS:

Flexible equipment connection when higher temperatures and compression movement is required

Thermal expansion of piping

TEMPERATURE: to 480°F

Specification

| Order | Specification(two waves) | Nominal diameter | Compensation amount(mm) | Summit diameter(mm) | Length(mm) |

| 1 | 1.2" | DN32 | 60=±30 | 170 | 245 |

| 2 | 1.5" | DN40 | 60=±30 | 190 | 255 |

| 3 | 2" | DN50 | 60=±30 | 300 | 325 |

| 4 | 2.5" | DN65 | 60=±30 | 320 | 336 |

| 5 | 3" | DN 80 | 60=±30 | 360 | 340 |

| 6 | 4" | DN100 | 60=±30 | 400 | 350 |

| 7 | 5" | DN125 | 60=±30 | 433 | 360 |

| 8 | 6" | DN150 | 60=±30 | 477 | 385 |

| 9 | 8" | DN200 | 60=±30 | 527 | 390 |

| 10 | 10" | DN250 | 60=±30 | 579 | 420 |

| 11 | 12" | DN300 | 60=±30 | 635 | 435 |

| 12 | 14" | DN350 | 60=±30 | 635 | 440 |

| 13 | 16" | DN400 | 60=±30 | 760 | 460 |

| 14 | 18" | DN450 | 60=±30 | 810 | 460 |

| 15 | 20" | DN500 | 60=±30 | 860 | 460 |

| 16 | 2" four waves | DN50 | 120=±60 | 300 | 590 |

Related Products

Inquiry

Welcome to visit our website. If you need our products please write down any questions, we will reply as soon as possible.