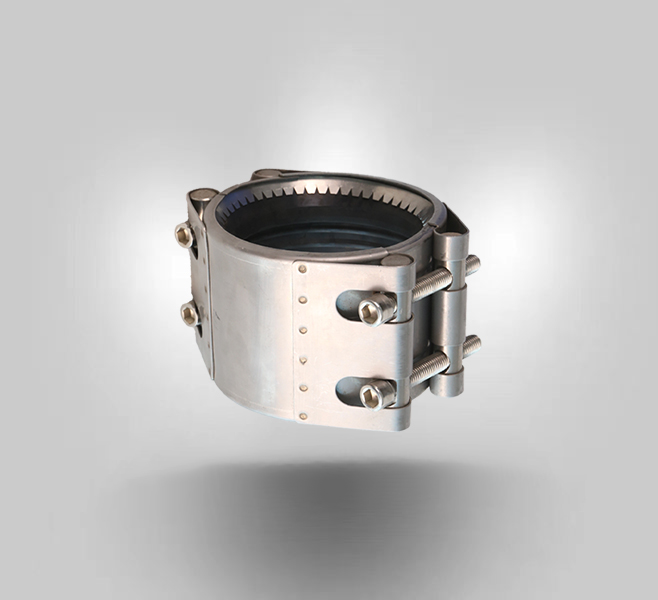

Pipe Repair Clamps

Water supply networks may suffer from leakages due to corrosion or cracking over time. Leaking water pipes can cause serious problems. The damaged pipes must be repaired as soon and safe as possible, but also durably to prevent waterloss. Repairs often cost a lot of time and money. The stainless steel repair clamp is a fast, professional and maintenance-free solution. Whether the damage is simple or complicated, with our stainless steel repair clamps, a pipe with a crack or hole can be repaired permanently. Repair clamps can either provide a temporary or permanent solution. They have a long service life similar to other piping components in the system. The use of high quality Stainless Steel and Rubber gaskets permits use of the product in a range of applications from reticulated water and sewerage to industrial use. A Repair Clamp’s variable OD Range enables a single clamp to adapt to any pipe OD within that variable range. This dramatically reduces the stocking requirement to cater for each individual pipe type and size.

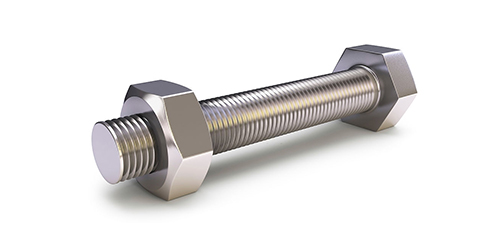

Locking Bolts and Bars:

Stainless Steel (T-304 and T-316 available)

Application:

Snap Clamps provide can quickly and economic repair to small damages to pipes. They are applied on board of ships and by plumbers for repairs above ground. The rubber partially covers the inside of the band and allows the repair of small holes caused by corrosion or frost.

-

Brand

BrandLUOYING

-

Size

SizeUp to DN 5000

-

Casing

CasingStainless Steel (304 and 316)

-

Customized

Customizedsupport

Product Range

-

Double tooth ring repair clamps

View More

-

Single tooth ring repair clamps

View More

-

Ring repair clamps with teeth

The use of high quality Stainless Steel and Nitrile Rubber gaskets permits use of the product in a range of applications from reticulated water and sewerage to industrial use. A Repair Clamp’s variable OD Range enables a single clamp to adapt to any pipe

View More

Customized Products

Technical Notes

Common installation problems

The multi-ply design

Saddle body and segments made of 304L Stainless Steel

request:

Bolts and washers made of stainless steel Screws and shafts are retained so they cannot fall out during installation.

The angular compensation of thermal expansion requires at least two, and for full compensation even three, angular expansion joints. Angular expansion joints offer a wide variety of combination options in so-called two-hinge or three-hinge systems.

Gasket:

Ethylene Propylene Diene Monomer (EPDM) compounded for water and sewer service. Other compounds available on request. Can be used as a coupling.

Compatible with steel, DI, HDPE, PVC, A/C and concrete pipe. Progressive self-sealing - The direct transmission of pressures onto the gasket generates the seal’s tightness, making use of the internal pressure. The gasket is not fixed onto the casing, therefore the clamp allows independent pipe movements.

Common installation problems

1.Be sure that the bolts are tightened to the proper torque shown on the label.

2.Rocks or debris between pipe and gasket.

3.Repair clamp not centered over damaged portion of pipe.

4.Make sure the pipe damage is between the gasket ribs.

5.Repair clamps should not be used as couplings.

6.Eliminate any dirt on threads of bolts or nuts.

7.When reinstalling parts with stainless steel hardware there may be a loss in pressure holding ability due.

Advantage

Nsure that the hose meets the published levels.-

torque

Low torque requirement. and Provides a positive seal on leaking pipes. -

Compatible

Compatible with rigid pipe.Lightweight.and Few bolts. -

integrity

Materials do not compromise the integrity of the pipeline. -

easy

loose pieces in the eld. and Captive bolt design makes installation easy and eliminates -

Constructed

Constructed of high strength corrosion resistant materials. -

304

Type 304 stainless steel or other stainless steel

Expansion joint accessories

Quality decides value-

Flange

Piping components can be bolted together between flanges. Flanges are used to connect pipes with each other, to valves, to fittings, and to specialty items such as strainers and pressure vessels. A cover plate can be connected to create a "blind flange" Flanges are joined by bolting, and sealing is often completed with the use of gaskets or other methods. Mechanical means to mitigate effects of leaks, like spray guards or specific spray flanges, may be included. Industries where flammable, volatile, toxic or corrosive substances are being processed have greater need of special protection at flanged connections. Flange guards can provide that added level of protection to ensure safety.

-

Covers

Fasteners are used for fastening and securing materials such as wood, metal, plastic, or concrete. They include nuts and bolts, threaded rods, structural bolts, machine screws, wedge anchors, washers, rivets, and more in a variety of types and sizes, including metric and inch.

-

Particulate barriers/purge connectors

In systems that have a media with significant particulate content (i.e. flash or catalyst), a barrier of ceramic fiber can be utilized to prevent corrosion and restricted bellows flexibility resulting from the accumulation of the particulate. Purge connectors may also be utilized to perform this same function. Internal liners must also be included in the design if the expansion joint includes purge connectors or particulate barriers.

-

Liners

A gasket is a mechanical seal which fills the space between two or more mating surfaces, generally to prevent leakage from or into the joined objects while under compression. It is a deformable material that is used to create a static seal and maintain that seal under various operating conditions in a mechanical assembly.